BEIJING KOREA TECHNOLOGY CASTER CO.,LTD |

|

How to do well the quality control and management of raw material

purchase in caster industry

Castor raw materials are very important to the production of castor

enterprises and are the basis to

ensure the product quality of castor enterprises. Experts believe that caster enterprises need to

control the procurement quality of raw materials and ensure product production quality and safety

from the aspects of evaluation and selection of raw material suppliers, strengthening the acceptance

of raw materials before warehousing, and improving the quality of warehouse management.

1, Classification of raw materials and evaluation and selection of

suppliers

1. Production raw materials shall be subject to classified

management and highlight key points

Caster enterprises need a wide variety of raw materials, but

different raw materials have different

effects on the product quality. In order to facilitate the key control of procurement quality, raw

materials shall be classified and managed according to the impact of raw materials on product

production quality.

It is generally divided into three categories:

Class a raw materials: refer to raw materials that may have a

direct and significant impact on product

production quality (such as direct impact on key functions and performance of products) in the process

of production and use.

Class B raw materials: refer to raw materials that may have an

indirect or important impact on product

quality in the process of production and use.

Class C raw materials: refer to raw materials that are generally

auxiliary parts and have a general or

slight impact on product quality.

2. The evaluation practice of raw material suppliers shows that

whether the quality of purchased raw

materials is stable depends largely on the quality management level of suppliers. Therefore, the

quality assurance capability of suppliers providing various raw materials shall be evaluated before

procurement.

(1) Evaluation of class a raw material suppliers

The evaluation of class a raw material suppliers is the key point.

Generally, it is necessary to conduct

on-site investigation and evaluate the operation status of their quality system, past supply, handling

and rectification ability in case of abnormal supply quality, as well as the ability of on-time delivery

and delivery quantity, the cost performance of their products, their after-sales service ability

(including after-sales service attitude, timeliness and effect), etc. At the same time, we should

also evaluate the quality of raw materials by consulting the data provided by the supplier,

investigating and understanding from other customers of the supplier, testing and trial using the

raw material samples provided, and regularly analyzing the results of the quality of raw materials

provided.

(2) Evaluation of class B and C raw material suppliers.

Generally, the purpose of supplier evaluation can be achieved by

consulting the data provided by

the supplier, testing and trial using the raw material samples provided, and analyzing the results of

regular analysis of raw material quality. For the evaluation of class B raw material suppliers, the

procurement department shall propose the "evaluation list of class B raw material suppliers" and

provide the relevant data of class B suppliers, or the quality, service, price and other data and

information such as the inspection and use of class B raw materials in the past, which shall be sent

to the relevant departments of technology, manufacturing, quality and finance for countersignature

(review) and submitted to the senior management for approval; For the evaluation of the capability

of class C raw material suppliers, the procurement department shall put forward the "evaluation list

of class C suppliers", which shall be countersigned by quality, finance, etc. and signed by the manager

of the procurement department.

1. Selection and determination of raw material suppliers qualified

raw material suppliers shall be

determined through selection. Obtaining a qualified raw material supplier depends on the above

evaluation results of the quality assurance ability of each supplier and factors such as production

and use, price, reputation and so on. Therefore, in the final determination of suppliers, several

suppliers of the same raw materials should be selected for comparison, especially when the

production and use conditions and the quality assurance capacity of each supplier are basically

the same.

2, Strictly control the incoming of raw materials. Purchasing raw

materials from qualified suppliers

is not everything. A qualified supplier only indicates that the supplier has the basic conditions to

provide raw materials with relatively stable quality. It is uncertain whether there is a shortage in the

quantity of raw materials actually delivered and whether the quality can meet the production

requirements. Therefore, the incoming quality of raw materials shall be strictly controlled according

to the following requirements before entering the factory.

3. Acceptance of raw materials without inspection. The acceptance

shall be conducted according to

the raw material purchase contract, the quality certificate, material certificate and other quality

certificates accompanying the goods; For individual low value consumables that are difficult to issue

corresponding certificate of conformity and material certificate, samples must be provided in advance.

Raw materials without certificate and material certificate shall be rejected for acceptance and

warehousing.

Working principle, use and maintenance of caster press

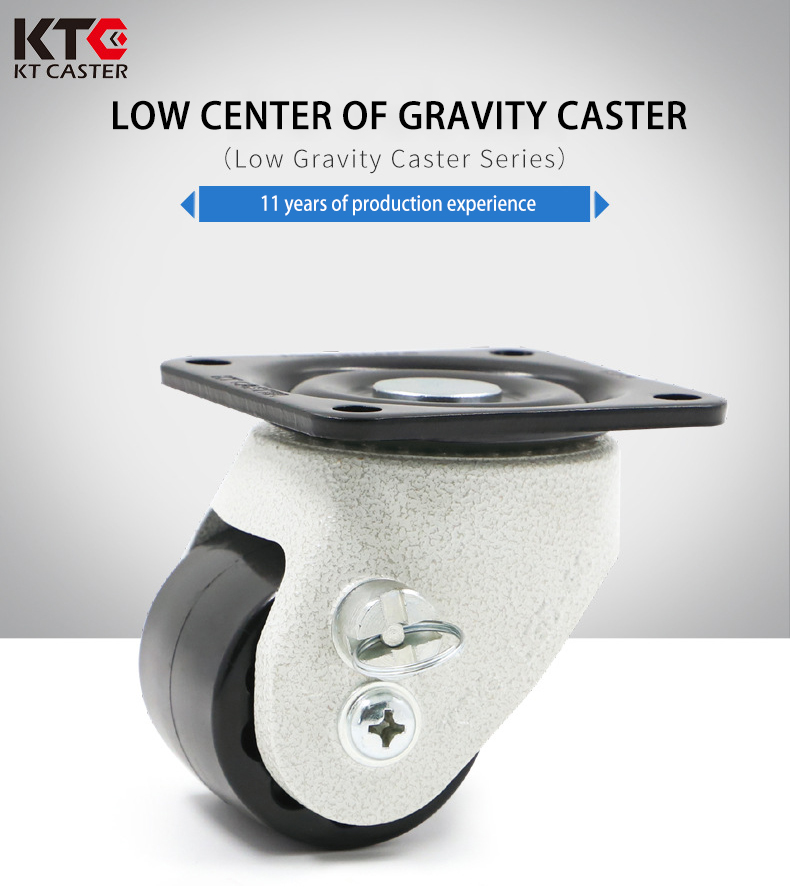

Industrial Swivel Casters Parameter

| Wheel material | Nylon6 |

| Load Capacity | 540KG |

| Wheel Diameter | 60mm |

| Color | white |

| Tread Width | 55mm |

| Load Height | 90MM |

Industrial Swivel Casters Describe

Industrial Swivel Casters Size

Industrial Swivel Casters Material

| Name | Material | Treatment | |

| 1 | Caster Seat | Cold-rolled carbon steel | Black Coated/Zn Galvanized |

| 2 | Body | Aluminum alloy | Ivory/Powder Coated |

| 3 | Ball | Bearing Steel | Ni-Cr |

| 4 | Brake | Steel 45 | Zn Galvanized |

| 5 | Pin | Steel 10 | Zn Galvanized |

| 6 | Wheel | PA6 | Black |

Industrial Swivel Casters Scope of application

KTC (Bejing Korea Technology Caster Co., Ltd.) was founded in 2007. KTC is a modern

company specialzingin the production of multi function &high quality CASTER and

KT FOOT based on best design and design technology.

The company is headquartered in Niulanshan Industrial Zone,Shunyi District, Beijing. KTC

adopts international advanced production testing equipments, professional intelligent

production management system and professional design flow. Now the company produces

multi function & high quality production, such as KT CASTER and KT FOOT, among which

high quality of height adjusting CASTER,shockproof type CASTER, high quality of height

adjusting CASTER, shockproof type CASTER,high load CASTER and level adjusting FOOT

are widely used in the world's advanced automation equipment and semiconductor e

quipment industry.

In order to manufacture the world's highest level of products,KTC

use the best processing

technology and equipment. And KTC continuously launches world top level of new products.

KTC's s also has set up a branch in Korea, so it is favored by theusers of various fields around

the world.