Henan Zhengyang Machinery Equipment Co., Ltd. |

|

Verified Suppliers

|

|

Raw Materials | The raw materials should meet the requirements of GB/T467-2010

cathode copper No.1 standard copper Cu-CATH-2 |

Battery Cover Remover | 2200*2000*1300 mm |

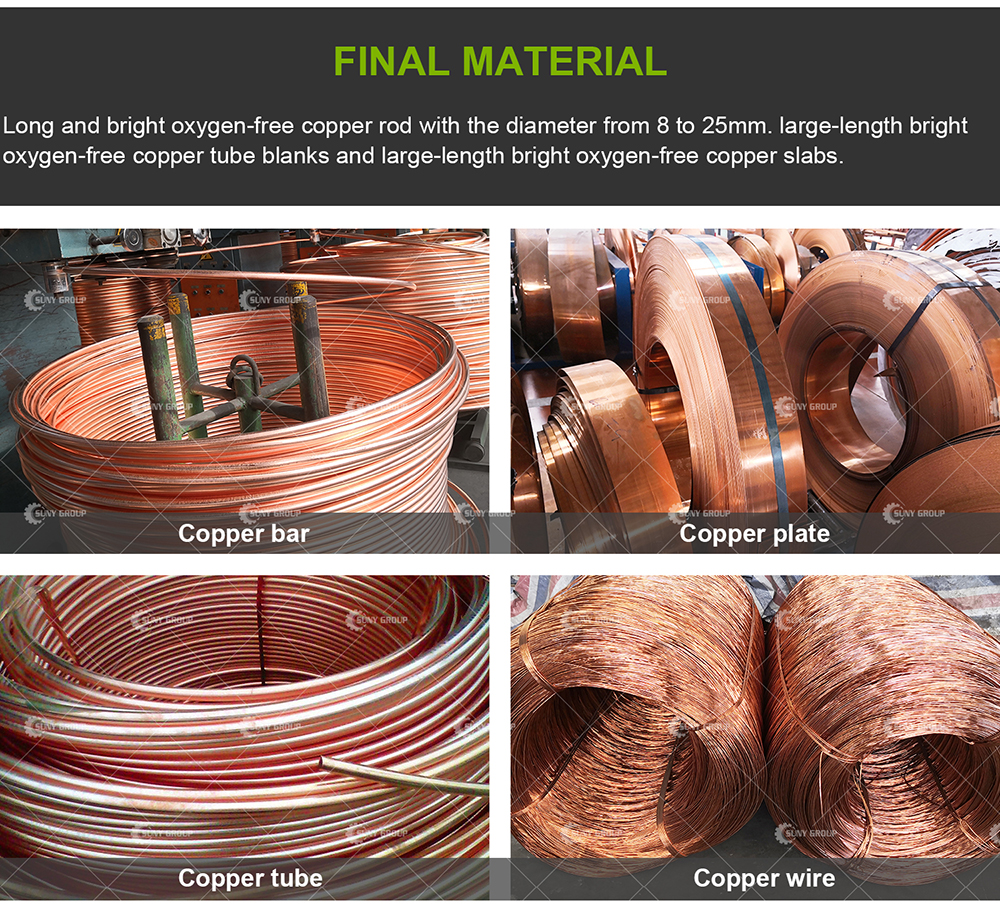

Copper Rod | Copper rod technical indicators should meet the GB/T3952-2008

standard |

Density | ~8.9Kg/dm3 |

Tensile Strength | >170N/mm2 |

Soft Electrical Conductivity | >100% IACS ( 2m2n Flexble Wire ) |

Soft Electrical Resistivity | >0.15328Ωg/m2 |

Elongation | >37% |

Oxygen Content | ≤20ppm |

Capacity | 3000 - 12000T/Year |

Furnace Number | 2 Melting Furnace+1 Heat Preservation Furnace |

Casting Rod Number | 24 Pcs |

Casting Rob Diameter | φ8mm ~ φ20mm |

Upward Speed | 6.0 ~ 2800mm/min |

Upward Circular Pitch | 3-6mm ( Adjustable ) |

Traction Frequency | 0 ~ 800 times/time |

Traction Way | Servo Motor Tranction |

Winding Specification | φ1000xφ1550x800 ( mm ) |

Voltage | 380V, 50Hz, 3Phase |

Melting Copper Speed | 1550 Kg/H |

Maximum Operating Power | ≤560 Kw |

Power Consumption | ≤330 Kwh/T |