Suzhou Forestry Technologies Co., Ltd. |

|

Verified Suppliers

|

|

Pressurized refiner can be used for MDF/HDF production line with capacity range from 30,000 to 200,000cbm per year

5~30 Tons Per Hour Fiber Making Refiner for MDF/HDF Production Line

Description

A preferred material for furniture, flooring or ceiling panelling:

medium-density fibreboards (MDF) are in use around the world. Their

quality depends on proper production. Büttner supplies the

wood-based panels industry with energy systems, drying systems and

burners, which ensure that wood fibres are quickly and efficiently

dried, before they are pressed.

Medium-density fibreboards are made of wood fibres and

characterised by their especially homogeneous structure. This

allows for the edges to be machined directly as well as a direct

painting process. MDF is utilised both in furniture construction

and in the production of laminate flooring or ceiling panelling.

Medium-density fibreboards are normally produced from fine wood fibres and glue. Depending on the region and availability, pine, spruce, beech, poplar, as well as eucalyptus and rubberwood trees are used. After the wood has been reduced to fibres, it is mixed with glue in a refiner and then dried in flash tube dryers. The required thermal energy is normally generated by energy systems, which burn both the waste material from the production process as well as purchased fuels such as biomass, oil or gas. The drying system can be heated directly with flue gas, turbine exhaust and burners, as well as indirectly with steam.

BM pressurized refiner adopts the patents and combined international advanced technology. The technical data and performance are close to the advanced level of world-famous similar products. The refiner has advanced structure, high automatic and easy operation, reliable and precision running, which can produce high quality fiber with lower moisture.

Pressurized refiner can be used for MDF/HDF production line with capacity range from 30,000 to 200,000cbm per year.

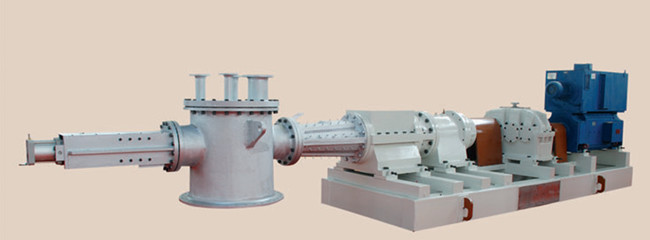

Assembly of refiner system

Main technical data

| SN | Item | Model | 42 | 42 | 44 | 45/48 | 50/54 | 54/58 |

| Cacacity(ton/h) | 5~7 | >7 | 10-11 | 13-18 | 20-26 | 26-30 | ||

| 1 | Feeding screw | Diameter(mm/inch) | Φ355/14 | Φ355/14 | Φ406/16 | Φ406/16 | Φ475/18 | Φ500/20 |

| 2 | Motor power(kW) | 250(DC) | 250(DC) | 315/355(DC) | 406(DC) | 450(DC) | 550(DC) | |

| 3 | Size | Output diameter(mm) | Φ1050 | Φ1050 | Φ1175 | Φ1175 | Φ1370 | Φ1600 |

| 4 | Height(mm) | 7000 | 7000 | 9000 | 9000 | 9000 | 9000 | |

| 6 | Motor power of conveying screw(kW) | 15 | 30(DC) | 30(DC) | 45(DC) | 75(DC) | 75(DC) | |

| 7 | Size of conveying screw(inch) | / | 16 | 16 | 16 | 18 | 20 | |

| 8 | Main motor power(kW) | 1600-2000 | 1600-2000 | 2240 | 3000-3550 | 4000-4500 | 4500-5600 | |

| 9 | Diamteter of refiner segment(inch) | 42,44 | 42,44 | 44 | 45,48 | 50,52,54 | 54,58 | |

| 10 | Seal of main shaft | Mechnical seal | Mechnical seal | Mechnical seal | Mechnical seal | Mechnical seal | Mechnical seal | |

Key parts of refiner

With large compression ratio, wood chips are de-watered during conveying with the new feeding plug screw, which reduce the drying energy, meanwhile, the wood chips are crushed, which is good for grinding. Structure distinguishing feature: overlay and coat one layer of wear-resistance material, improve the plug screw service life. Inside the cone pipe, reinforced bar are inlayed, which can reduce maintenance cost. Speed-adjustable DC motor can provide large torque and good performance.

Large diameter stainless steel vertical digester vessel has lower height which has lower requirements for the civil construction. In desigh of MDF pressurized refiner whose capacity is more than 100,000.0 cbm per year, double screw feed system are used, which can supply the raw material continuously to improve the fiber quality.

A fantanstic way to make wood chips to wood fiber.