Jiangsu Lebron Machinery Technology Co., Ltd. |

|

Good Service PLC Control Automatic Door Frame Roll Forming Machine Gi And Gl Material

1. Technical Parameters:

| No. | Item | Specification |

| 1 | Can Formed Material | GI,AI |

| 2 | Equipment operation | Automatic |

| 3 | Voltage | 380V 60Hz 3Phase or as your requirement |

| 4 | Thickness of sheet (mm) | 0.8-1.2mm |

| 5 | Material width(mm) | As your requirement |

| 6 | Cover Width of the sheet after formed | as your drawing |

| 7 | The size of the roll forming machine | 6000mmx800mmx1400mm |

| 8 | Speed | 8-15m/min |

| 9 | Diameter of shaft | 40mm |

| 10 | Weight of the Machine | 3000-3500KGS |

| 11 | Material of rollers | C45 steel quenched and chromed |

| 12 | Motor brand | Siemens or Guomao |

| 13 | PLC | Siemens or Delta or Mitsubushi |

| 14 | Total power (kw) | 11kw |

| 15 | Power of hydraulic system | 5.5kw |

| 16 | Power of main molding core | 5.5kw |

2. Description of Rolling Shutter Door T Profile Machine

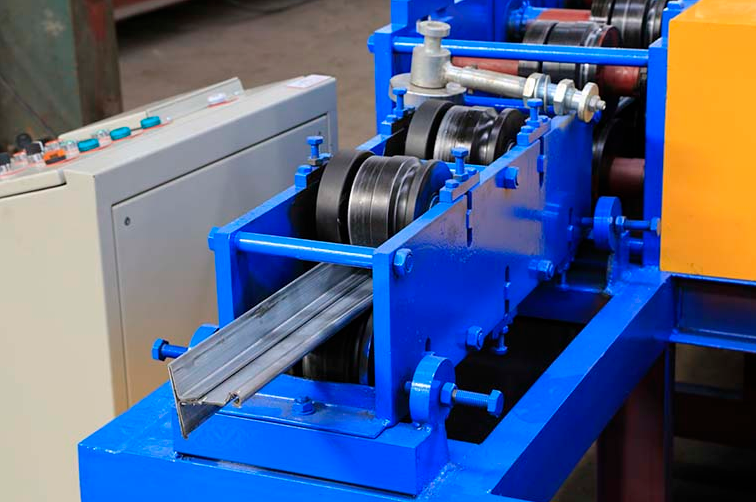

Rolling Shutter Door T Profile Machine are always required for the manufacturing of guide rails for rolling shutter doors to raise up and lowered down from galvanized steel strips of 1.2-2.0mm thickness.

There are a variety of rolling shutter door tracks used in the markets, T profile is one type. So the width of steel strips varies accordingly. In the rolling shutter tracks or rails, always the galvanized steel rolling shutter slats, pre-painted rolling shutter door panels and PU Rolling Shutter Slats are guided.

Due to the heavy duty materials a Rolling Shutter Door T Profile Machine usually bends, there are two types of transmission available for customers to choose: Chain-brackets transmission and Gear-box transmission.

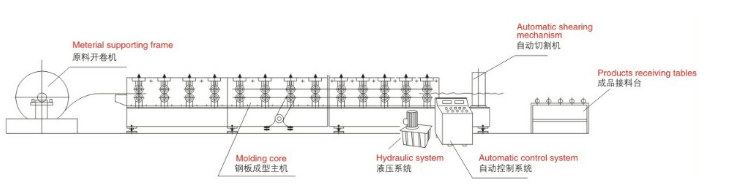

A Rolling Shutter Door T Profile Machine for the production of rolling shutter door guide rails generally consists of a decoiler, leveler, main roll forming machine, transmission system (chain-brackets or gearbox), cutting tool, hydraulic oil pump, PLC control cabinet and runout tables.

3. Main Components and features of the Rolling Shutter Door T Profile Machine

Decoilers: The decoiler range is one of the largest and most powerful in the world. So we offering ranges from light, mechanically-operated options all the way up to a completely motorised decoiler with a quick charge integrated system which has a capacity of up to 15 tonnes.

Plate end welding: This system allows plate ends to be welded quickly and automatically, reducing waste and downtime.

Intermediate punching and forming station: Can incorporate several intermediate stations for punching, forming or marking. The different options available are endless. Starting with a single punching or forming unit right the way through to a multi-tool CNC press.

Vertical plate stock: This system eliminates the need for a traditional roll-forming pit. Allowing the plate to accumulate, ready for the forming process.

CNC control: Our user-friendly CNC touch screen display enables full control of the automatic line in a synchronised and also in a autonomous way.

Versatility, diversity and production optimization: Depending on the customer’s needs, our roll forming lines can be equipped with several different, interchangeable systems to easily meet specific requirements. Quick cassette changes along with adjustable tooling to produce a variety of bespoke profiles with different dimensions make both efficient and versatile.

Cut-to-lenght: There is also an option to equip our roll-forming machines with stationary or high speed cut-to-length systems.

Offload systems: To increase the efficacy of the roll forming, an automatic offload system can be incorporated to stack products on pallets or fill stillages.

4. COMPONENT FOR unistrut channel roll forming machinery

| COMPONENT FOR unistrut channel roll forming machinery | |||

| Name | Quantity | Units | |

| Decoiler | 1 | Set | |

| Main Machine | Feeding device | 1 | Set |

| Roll forming system | 1 | Set | |

| Cut Equipment | 1 | Set | |

| Hydraulic system | 1 | Set | |

| Electric control system | 1 | Set | |

| Supporter/Automatic Stacker | 1 | Set | |

5. Our Service

Install and Training:

If buyers come to our factory to inspect, the training to install and operate is provided face to face.

If not, manual and video is provided to show how to install and operate.

After-sale Service:

We provide 12-hour online service for our customers. Phone: +86 15821208506

a .The seller will debug the machines freely in China, and the traffic expense in China of the technique people will be paid by the seller.

When technique men go to the buyer's place to debug the machines, the buyer should pay the

expense of accommodation, and round-trip tickets for the seller’s men. and pay the technician USD60 per day.

b. If the buyer sends people to receive the training of the operation given by the seller, during the training period, the seller should pay the expense of accommodation, and traffic for the buyer's men.