SHENZHEN JIATUO PLASTIC MACHINERY CO.,LTD |

|

Verified Suppliers

|

|

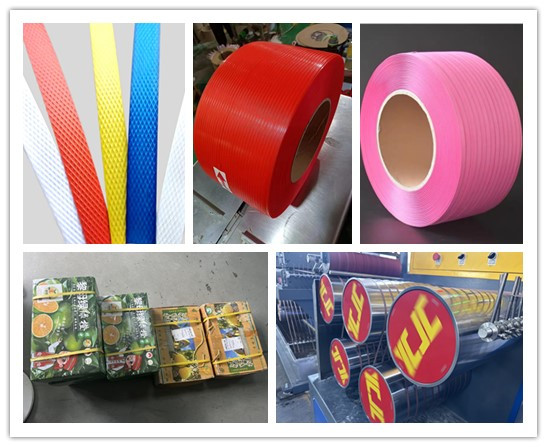

PP Strap Making Machine, also known as Polypropylene Banding Machine or Plastic Strapping Manufacturing Machine, is a highly efficient and reliable machine used for producing high-quality polypropylene straps. These straps are widely used in industries such as packaging, shipping, and logistics to secure and bundle various types of goods and packages.

The PP Strap Making Machine is designed and manufactured using advanced technology and high-quality materials to ensure long-lasting performance and durability. It is capable of producing PP straps with a thickness ranging from 0.4mm to 1.2mm, making it suitable for a wide range of applications.

The PP Strap Making Machine is equipped with a video outgoing-inspection feature, which allows for real-time monitoring and quality control of the production process. This ensures that only straps of the highest quality are produced, reducing the chances of defects and increasing customer satisfaction.

The PP Strap Making Machine is available with both single and double screw extruders, allowing for flexibility in production. The extruders are made of high-quality materials and are designed to provide precise and consistent melting and extrusion of the raw materials, resulting in uniform and high-quality straps.

The screws used in the PP Strap Making Machine are made of 38CrMoALA, a high-strength and wear-resistant material. This ensures the longevity and efficiency of the machine, even when used for prolonged periods.

The PP Strap Making Machine is compatible with both 380V and 220V power supplies, making it suitable for use in various countries and regions. The power supply can also be customized according to the specific needs of the customer.

The PP Strap Making Machine is a highly efficient and reliable machine that is essential for the production of high-quality polypropylene straps. With its advanced technology, video outgoing-inspection, and customizable features, it is the perfect solution for any business looking to improve their packaging and bundling processes. Invest in the PP Strap Making Machine today and experience increased productivity and cost-effectiveness in your operations.

| Product Name | PP Strap Making Machine |

|---|---|

| Automatic Grade | Fully Automatic |

| Screw Diameter | 110*3300mm |

| Plastic Processed | PP |

| Machine Type | Single Screw Extrusion Line |

| Thickness | 0.4-1.2mm±0.05mm |

| Strap Thickness | 0.4-1.2mm |

| Winder | Double Station Winder |

| Power Supply | 380V/220V (customizable) |

| Strap Speed | >280m/min |

| Strap Tension | Adjustable |

| Strap Core Type | Paper/Plastic |

Welcome to the world of PP Strap Making Machine, a highly advanced and efficient product of modern technology. This machine is designed and manufactured to cater to the growing demand for high-quality polypropylene (PP) straps in various industries. With its cutting-edge features and superior performance, it has become an essential equipment for PP strap manufacturing companies.

PP Strap Making Machine, also known as Polypropylene Banding Machine, is a specialized equipment used for producing PP straps in different sizes and thicknesses. It is a single or double screw extruder that can produce straps with a speed of over 280m/min, making it one of the fastest machines in the market. The machine is equipped with a double station winder, ensuring a smooth and continuous production process.

PP Strap Making Machine is widely used in various industries such as packaging, logistics, and transportation, where PP straps are essential for securing and bundling goods. It is also used in the construction industry for bundling and reinforcing building materials. With its high-speed production capacity and ability to produce straps with different specifications, this machine has become a go-to choice for many manufacturers.

PP Strap Making Machine boasts of several features that make it stand out from its competitors. Some of its key features include:

With these features, PP Strap Making Machine offers several benefits to its users, such as increased production capacity, reduced downtime, and cost-effectiveness.

This product is certified with IS CEO, ensuring its compliance with international quality standards. It is also packed with plastic film for safe transportation and storage. The minimum order quantity for this product is 1 set, and the delivery time is 30-40 days, depending on the order size.

In the fast-paced world of manufacturing, PP Strap Making Machine has become a game-changer for the polypropylene strap manufacturing industry. With its high-speed production, customization options, and durable performance, it has revolutionized the way PP straps are produced. Choose PP Strap Making Machine for your business and experience a new level of efficiency and productivity.

Brand Name: PP Strap Making Machine

Model Number: JTPP-110

Place of Origin: CHINA

Certification: ISO9001

Minimum Order Quantity: 1 SET

Price: Negotiable

Packaging Details: Plastic Film

Delivery Time: 30-40 days

Screw Diameter (mm): 110*3300mm

Extruder: Single or Double Screw

Strap Thickness: 0.4-1.2mm

Winder: Double Station Winder

Strap Core Type: Paper/Plastic

Key words: Polypropylene Strap Making Machine, Plastic Strap Manufacture Equipment, Polypropylene Strapping Machine

The PP Strap Making Machine will be securely packaged to ensure it arrives safely to its destination. The packaging will consist of:

Once packaged, the PP Strap Making Machine will be shipped via a reputable shipping company to the designated address. The shipping process will include:

We take great care in packaging and shipping our products to ensure they arrive in perfect condition. If there are any issues with the shipment, our customer service team will be happy to assist in resolving them.