Qingdao Ruly Steel Engineering Co.,Ltd |

|

Verified Suppliers

|

|

Prefabricated Car Repair Shop Steel Structure Building Steel Structure Warehouse With Overhead Crane

Having an overhead crane in a workshop provides several advantages. Here are some benefits of having a workshop equipped with a crane:

Increased Efficiency: The presence of an overhead crane in a workshop significantly improves efficiency. It allows for the easy movement of heavy materials, equipment, and products within the workspace. This eliminates the need for manual lifting and carrying, saving time and reducing the risk of injuries.

Enhanced Safety: Overhead cranes are designed with safety features such as limit switches, overload protection, and emergency stop buttons. These features ensure the safe handling of heavy loads, reducing the chances of accidents and injuries. Additionally, using a crane minimizes the risk of damage to the materials being transported.

Versatility: Overhead cranes are highly versatile and can handle a wide range of loads, from small components to large machinery. They can be equipped with various attachments such as hooks, magnets, and grabs, allowing for efficient handling of different types of materials.

Optimal Space Utilization: Overhead cranes utilize the vertical space of a workshop, maximizing the available floor area. Since the crane operates overhead, it doesn't obstruct the floor space, enabling workers to move freely and perform their tasks without hindrance. This is particularly beneficial in workshops with limited space.

Increased Productivity: The ability to quickly and safely move heavy loads with an overhead crane contributes to increased productivity. It reduces downtime associated with manual handling, allowing workers to focus on their core tasks. Moreover, cranes enable faster assembly, disassembly, and maintenance of equipment, leading to improved workflow and overall productivity.

Cost Savings: While the initial investment in an overhead crane may be significant, it can result in long-term cost savings. By minimizing the reliance on manual labor for heavy lifting, the crane reduces labor costs and the potential for worker injuries. Additionally, efficient material handling provided by the crane can prevent damage to products and equipment, saving on repair or replacement expenses.

In summary, having a workshop equipped with an overhead crane offers benefits such as increased efficiency, enhanced safety, versatility in handling various loads, optimal space utilization, improved productivity, and potential cost savings.

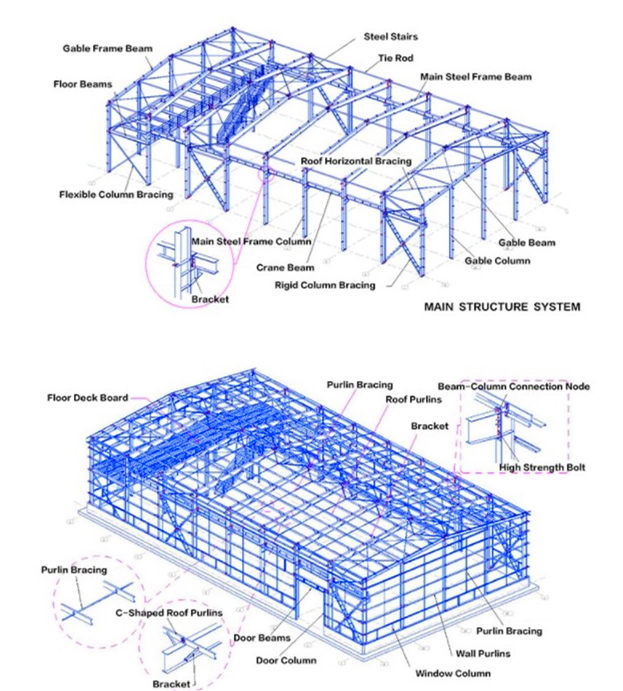

| Main Steel Frame System | |

| Main structure | H section steel Q355, alkyd painting, two primary painting, two finish painting. |

| Roof purlin | XZ160*60*20*2.5, galvanized |

| Wall purlin | XZ160*60*20*2.5, galvanized |

| Intensive bolt | Grade 10.9 |

| Turn buckle bolt | M20+2, steel Q235, processing |

| Anchor bolt | M24, steel Q235, processing |

| Ordinary bolt | Galvanized bolt M20 |

| Ordinary bolt | Galvanized bolt M12 |

| Brace nut | Galvanized bolt M12 |

| Bracing System | |

| Cross brace | Φ20 round steel bar Q235, process and painted (alkyd painting) |

| Angle brace | L50*5 angle steel Q235, process and painted (alkyd painting) |

| Column bracing | Φ25 round steel bar Q235, process and painted (alkyd painting) |

| Tie bar | Φ127*3 steel pipe Q235, process and painted (alkyd painting) |

| Batter brace | Φ32*2.5, Φ12 round steel bar Q235, process and painted (alkyd painting) |

| Wall & Roof System | |

| Roof panel | Corrugated steel plate or sandwich panel (EPS/fiber glass/rock wool/PU) |

| Wall panel | Corrugated steel plate or sandwich panel (EPS/fiber glass/rock wool/PU) |

| Edge cover | 0.5mm color plate, angle Alu. |

| Fittings & accessories | Nails, glue etc. |

| Unpowered ventilator | Diameter Φ600, stainless steel |

| Sky lighting band | 1.2mm FRP, double layer |

| Sliding door | sandwich panel door |

| Roof drainage system | |

| Gutter | 0.5mm color steel plate |

| Rainspout pipes | Φ110 PVC pipe |

Qingdao Ruly Steel Engineering Co., Ltd is a professional steel

structure design, research, fabrication and construction company,

located in Qingdao, China. Our company's steel structure processing

plant now covers an area of 35, 000 square meters, plant20, 000

square meters. More than 100 employees. The monthly production

capacity for steel structure is more than 2000 Tons.

We could contract the projects such as prefabricated steel

structure warehouse, workshop, storage sheds, garage, hangar,

chicken shed, car parking, showroom, office buildings, gym,

dormitory building, high rise steel residence buildings,

oli&gas project, power station, infrastructure buildings, etc.

At present, Our products have been exported to Southeast Asia,

South America, Middle East and Africa, Australia, etc. In order to

serve better for the exported project, we get certification of AWS

D1.1, CE(EN 1090-1: 2009+A1: 2011), ISO 14001, ISO9001, ISO45001,

AS/NZS 1554, SGS and BV Certification.

We provide one-stop service for steel structure project, just tell

us your requirement, and we will give you what you need.

All the structure components, panels,bolts and sort of accessories will bewell packed with standard package suitable ocean transportation and loaded into 40'HQ.

All the products are loaded at the loading site of our factory using crane and forklift by our skilled workers,who will prevent the goods to be damaged.

1. Professional design team, we could design the drawing as your requirement or calculate the steel quantity based on your drawing.

2. Skilled fabrication team and advanced equipment. We make the independent production schedule to each project.

3. One-stop service: We have completed lots such kinds of projects, we could provide the integrated proposal for your project.

4. Professional QC team will guarantee that we will provide the production and service as your request.

5. After sales service: If it has any questions that need us to do in your process of using, such as the maintain of outside insulation and steel components, just tell us , we will try to provide the service as well as we can.

The following questions we need to know before offering the quotation. Just feel free to fill in what you know.

| 1 | Location (where will it be built?) | _____country, area |

| 2 | Size: length*width*height | _____mm*_____mm*_____mm |

| 3 | wind load (max. wind speed) | _____kn/m2, _____km/h, _____m/s |

| 4 | snow load (max. snow height) | _____kn/m2, _____mm |

| 5 | anti-earthquake | _____level |

| 6 | brickwall needed or not | If yes, 1.2m high or 1.5m high |

| 7 | thermal insulation | If yes, EPS, fiberglass wool, rockwool, PU sandwich panels will be

suggested; . if not, the metal steel sheets will be ok. The cost of

the latter will be much lower than that of the former |

| 8 | door quantity & size | _____units, _____(width)mm*_____(height)mm |

| 9 | window quanity & size | _____units, _____(width)mm*_____(height)mm |

| 10 | crane needed or not | If yes, _____units, max. lifting weight____tons; max. lifting height _____m |