Cangzhou Best Machinery Co., Ltd |

|

Verified Suppliers

|

|

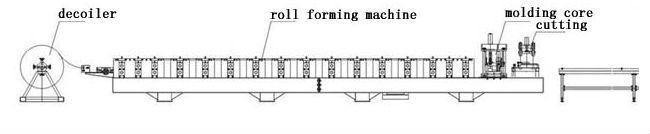

Man-made uncoiler →Roll forming machine →computer control system →hydraulic control system →cutting

Machine components list:

| Name | NO. | Unit |

| 1.De-coiler | 2 | set |

| 2.Forming machine | 1 | set |

| 3.Cutting device | 1 | set |

| 4.PLC control box | 1 | set |

| 5.Hydraulic pump station | 1 | set |

| 6.Production support table | 1 | set |

Decoiler

| Type | Manual type(standard) | Hydraulic type(option) |

| Photo | ||

| Width | 1250mm | 1500mm |

| Capacity | Max 5tons | From 5-15 tons |

| Inner diameter | φ508-610mm | φ508-610mm |

| Outer diameter | φ1500mm | φ1800mm |

roll forming

| Item | Parameter detail | ||||||||

| Processing Material | GI and PPGI | ||||||||

| Material thickness | 0.25-0.8mm | ||||||||

| Machine frame | 360#H steel, Adopt diagonal line welding, leveling instrument measurement to make sure the final frame is high-precision | ||||||||

| Machine siding panel |

| ||||||||

| Forming stations | 10-22 stations(according to the profiles) | ||||||||

| Machine rollers | high grade No.45 forged steel,plated hard chroming with thickness

0.05mm Processing way:cutting--drilling--CNC lathing--quenching--CNC lathing--chroming | ||||||||

| Machine Shaft | φ60-70mm high garde No.45 steel after treatment, | ||||||||

| Machine spacers | CNC lathing in high-precision | ||||||||

| Machine bearings | China Haerbin bearing or SKF international bearing(option) | ||||||||

| Driving system | 1 inch chain or gear box(option) | ||||||||

| Machine power | 3kw-5.5kw(according to the profiles) | ||||||||

| Machine working speed | 8-12m/min or 10-30m/min(option) | ||||||||

| Machine adjust type | After machine installation, we will test it ourselves, compare with the profile drawing, the difference is controlled in 0.5mm |

Cutting

| Type | bearing sliding type |

| Blade material | Cr12mov quenching and grinding |

| Frame processing | the whole bottom frame is grinding for high-precision |

| Blade processing | wire-electrode cutting, but the upper balde can not be straight. this is technology |

| Working | Hydraulic type |

Stacker

| Type | Manual | Auto(option) |

| Length | 1.5m-2m | 6m or 12m |

PLC

| Main item | Parameter detail |

| PLC | Delta(standard) or according to your request |

| Inverter | China brand(standard) or according to your request |

| Touch screen | Mcgs(standard) or according to your request |

| Encoder | China brand(standard) or according to your request |

| Voltage/HZ/Phase | 380v/50-60hz/3phase |

Hydraulic pump

| Main Item | Parameter detail |

| Motor | 3kw China brand or according to your request |

| Pump | China brand or according to your request |

| Solenoid valve | China brand or according to your request |

| Cooling system | Cooling fan |