Cangzhou Best Machinery Co., Ltd |

|

Verified Suppliers

|

|

8-12m/min Production Capacity 3kw Roofing Panel Roll Forming Making Machine

1. Main Parameters:

| No. | Item | Specification |

| 1. | Can Formed Material | PPGI,GI,AI |

| 2. | Equipment operation | Automatic |

| 3. | Voltage | 380V 50Hz 3Phase or as your requirement |

| 4. | Thickness of sheet (mm) | 0.3-0.8mm |

| 5. | Material width(mm) | 914/1000/1219/1250mm |

| 6. | Cover Width of the sheet after formed | As profile drawing |

| 7. | The size of the roll forming machine | 7500mmx1700mmx1300mm |

| 8. | Speed | 8-12m/min(also have high spped) |

| 9. | Diameter of shaft | 70mm |

| 10. | Weight of the Machine | 4000-4500KGS |

| 11. | Material of rollers | No. 45 steel quenched and chromed |

| 12. | Motor brand | Siemens or China brand |

| 13. | PLC | Siemens or Delta or Mitsubushi |

| 14. | Total power (kw) | 3+3KW |

| 15 | Power of hydraulic system | 3KW |

| 16. | Power of main molding core | 3KW |

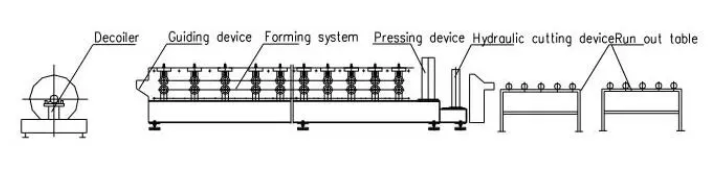

2. Working Flow:

Manual decoiling----feeding and guiding----roll forming----punching----cut to length----run out table

3. Product Application

Different roof panel forming machines can produce different shapes

of steel roof wall sheets according to the client’s profile

drawings and requirements. The steel roof, wall sheets are new

building materials with various thickness and colors. The finished

products are used as the roof and walls of gymnasiums, airports,

theatres, factories, warehouses, garages, exhibition centers etc.

The complete machine includes the uncoiler, main forming machine,

computer controlling system and run out tables.

4. Our Service:

1). Payment Term: 30% of the total contract value paid by T/T as down payment, the rest 70% of the total contract value to be paid by T/T after inspection by buyer in seller’s factory while before delivery.

2). Delivery Time: The seller guarantees the equipment will be ready for shipment within 30working days after receipt of deposit from the buyer.

3). Service: We could send the technician to your country to fix the machine if you need.

4). Warranty: 24 months During the warranty, the replaceable parts are free, but the buyers need to pay for the shipping fee.

5. Packing:

Standard Export Packing.

1. One 40ft container for loading one set machine with manual

decoiler;

2. The whole Wiped Anti Rust Oil, PLC controller covered by foam

film;

3. Spare parts and some small parts packed in plastic tooling box;

4. All Components Fixed by steel wire with Container.

6. FAQ

Q: Are you manufacturer?

A: Yes, we are manufacturer.

Q: What kind of payment term you can do?

A: We are flexible about payment terms, please contact us for details.

Q: What info you need before you make the proposal for a roll

forming machine?

A: The profile drawings, material informations, your special

requirements.

Q: What I should do if I just start to know roll forming machinery?

A: Contact us immediately, we provide free consultant pre-sales

service.

Q: How to visit our company:

A: 1.Fly to Beijing airport: By high speed train From Beijing Nan

to Cangzhou Xi (1 hour),then we can pick up you.

2. Fly to Shanghai Airport: By high speed train From Shanghai

Hongqiao to Cangzhou Xi(4.5 hours),then we can pick up you.

3. Fly to Guangzhou aiport: By air From Guangzhou to Beijing

airtpot; By high speed train From Beijing Nan to Cangzhou Xi (1

hour),then we can pick up you.