Cangzhou Best Machinery Co., Ltd |

|

Verified Suppliers

|

|

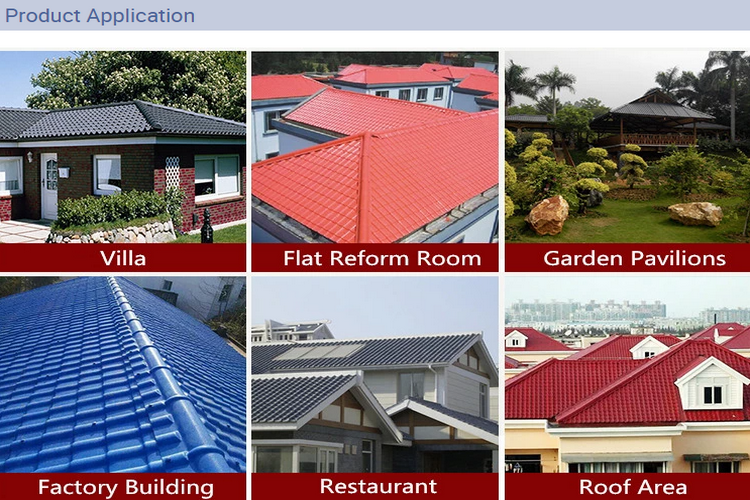

Description of application effect

After-sales Service Provided | Engineers available to service machinery overseas |

raw material | PPGI |

PLC | mitsubishi/delixi/siemens |

warranty | 18 months |

Cutting blade material | Cr12 Quenching |

Roller material | 45# Forged Steel |

Key Selling Points | Easy to operate |

Color | Customized |

2.main parameter table.

| Material thickness | 0.3~0.7mm |

| Material yield stress | 230~550 Mpa |

| Max. forming speed | 8~25m/min |

| Roller material | 45# steel with chrome treatment |

| Roller driven type | Chain transmission |

| Controller & operation | PLC & touch screen and button |

| Hydraulic system pressure | 12 Mpa |

| Hydraulic station motor power | 3 Kw |

| Main motor power | 4~7.5Kw |

| Total power | 7~10.5Kw |

| Total weight | About 6000~8000 Kgs |

| TRAPEZOID TILE ROLL FORMING MACHINE | |

| Feeding material | PPGI |

| Thickness of the plate | 0.3-0.8mm |

| Coil width | 914/1000/1200/1220/1250mm |

| Machine size | about 7000mmX1600mmX1000mm |

| Diameter of the axle | Φ70/Φ75mm |

| Rolling stages | 15-18 stages |

| Productivity | 8-12m/min |

| Total power | 4kw machine motor +4 kw pump station motor |

| Voltage | 220V 60Hz 3phase or as requirement |

| Weight | about 4.5T |

| Base frame | 300H steel |

| Side board thickness | 16mm |

| Cutting blade | Cr12 with heat treatment |

| Cutting system | Hydraulic cutting system after forming |

| Control cabinet | PLC and frequency changer in it |