Cangzhou Best Machinery Co., Ltd |

|

Verified Suppliers

|

|

High Quality 915 MM Building Structure Deck Floor Roll Forming Machine

Steel decking profile of various shapes and width. The formed structure bears more strength and can be easily fit with each other. They can be easily aligned with each other. The metal decks can bear high tensile loads. They can be used for the walls roofing’s and floorings of any warehouses, storage areas, factories, etc. They are cost effective than concrete structures and easily installing structure. Due to its light weight, transportation has become very easier.

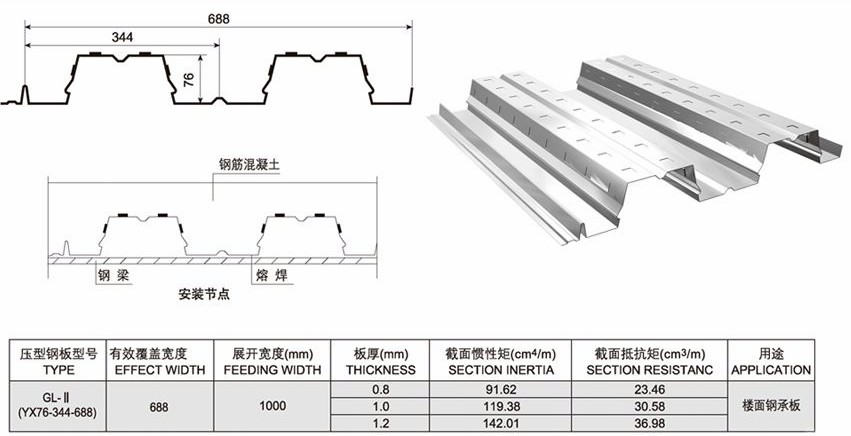

| Name of Roll Forming Machine | 688 Floor Deck Roll Forming Machine Floor Tile Material Making Machine | |

| Profile Drawing or Sample Picture |  | |

| 1 | Suitable raw material | PPGI/PPGL/GI/GL Steel Coils |

| 2 | Thickness of coil sheet | 0.3-0.8mm |

| 3 | Feeding Coil width | 1000mm |

| 4 | Effective width | 688mm |

| 5 | Under frame | 400H-beam |

| 6 | Diameter of Soild shaft | 70mm, high grade 45# steel, finish turning, cylindrical grinding, with keyway |

| 7 | Roller | High grade 45# steel, processed by CNC lathe, Quenched and tempered treatment, hard chrome coated 0.05-0.07mm |

| 8 | Thickness of middle plate | Guide pillar memorial archway |

| 9 | Forming stations | 26 |

| 10 | Drive type | By chain(1.0 inch) link bearing model 6210 |

| 11 | Power of main motor | 7.5kw with Cycloidal reducer, Lichao, Shanghai |

| 12 | Power of pump station | 4kw, Lichao, Shanghai |

| 13 | Forming speed | About 15-20m/min |

| 14 | Hydraulic cutting | Controlled by PLC |

| 15 | PLC | DELTA, TAIWAN / Mitsubishi, Japan |

| 16 | Material of cutting blade | Cr12Mov, quenching 58-62℃ |

| 17 | Frequency converter | It has the advantage of slowing down before cutting, to ensure the length accuracy(±1mm, far better than industrial standard ±3mm). |

| 18 | Switch | CHNT |

| 19 | Transducer | SAJ |

FAQ:

Q1. What's your payment terms and delivery time?

A1: 30% as the deposit by T/T in advance, 70% as the balance payment by

T/T after your inspect the machine well and before delivery. Of course your payment terms are acceptable.

After we get down payment, we will arrange production. About 30-45 days for delivery.

Q2. Do you have after-sales support?

A2: Yes, we are happy to provide advice and we also have skilled

technicians available across the world. We guarentee your machine

running well in order to make your business running well.

Q3. Do you sell only standard machines?

A3: No, customized service will be provided for all of our

customers. Most of our machines are built according to customers

specifications, using top brand components.

Q4. What will you do if the machine is broken?

A4: We provide 18 months free warranty and free technical support for the whole life of any machine.

If the broken parts can't repair, we can send the new parts replace the broken parts freely, but you need pay the express cost

by yourself. If it is beyond the warranty period, we can negotiate to solve the problem, and we supply the technical

support for the whole life of the equipment.

Q5. Can you be responsible for transport?

A5: Yes, please tell me the destination port or address. we have

rich experience in transporting.

Q6. How to visit your company?

A6: 1) Fly to Beijing airport, By high speed train From Beijing Nan

to Cangzhou Xi (1 hour).

2) Fly to Shanghai Airport: By high speed train From Shanghai

Hongqiao to Cangzhou Xi(4.5 hours), then we can pick up you.

Installation and Training:

① If buyers visit our factory and check the machine, we will teach

you how to install and use the machine, and also train your

workers/technician face to face.

② Without visiting, we will send you user manual and video to teach

you to install and operate.

③If buyer needs our technician to go to your local factory,please

arrange round trip tickets, food and hotel and everyday salary

USD100, visa cost and necessary things.