| Item | Parameter | Remark |

| Material | Type | Galvanized steel, colored steel | |

| Thickness (mm) | 0.75-1.25 | |

| Yield Strength (MPa) | 230 | |

| (mm) | 1220 | |

| Forming Speed (m/min) | About 15 | Cutting time excluded |

| Number of Roller | About 30 stands | Depend on actual design |

| Main Motor Power (kW) | 5.5 × 3 | Depend on actual design |

| Main Hydraulic Station Power (kW) | 5.5 | Depend on actual design |

| Decoiler Motor Power (kW) | 5.5 | Depend on actual design |

| Decoiler Hydraulic Station Power (kW) | 3 | Depend on actual design |

| Total Power (kW) | 30.5 | Depend on actual design |

| Power | AC440V, 60Hz, 3 Phase | |

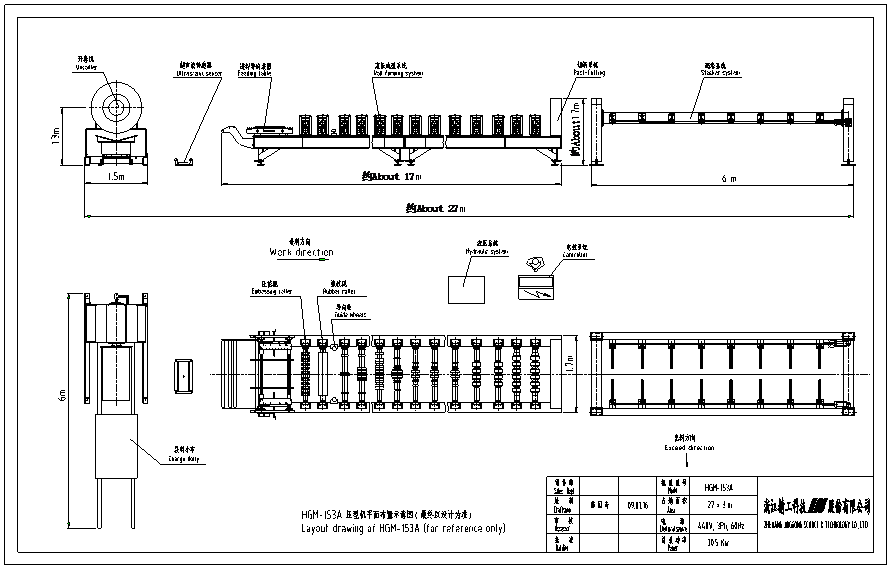

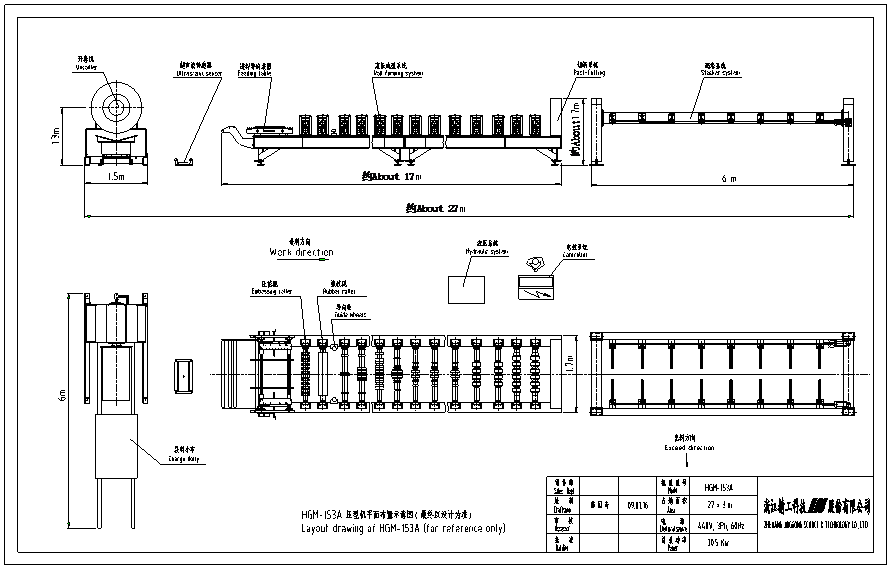

| Dimension (L × W × H) (m) | 27 × 3 × 2 | Depend on actual design |

Components

| Item | Quantity | Technical Description |

| Decoiler System | 6T automatic decoiler (JK6-1250AM) | 1 set | 1. Arm-type hydraulic expanding decoiler with electric motor. 2.

Supersonic control and coil car. |

| Main Forming System | Guiding device | 1 set | 1. Material of roller: 38CrMoAl, with surface nitrified. 2.

Material of roller shaft: 45# steel after quenching and tempering

treatment 3. Inner support structure of roller: column 4.

Back/forward movement of roller is driven by chain, and part of the

upward/downward movement is driven by gear. 5. Material of cutting

blade: Cr12, quenching treated. |

| Roll forming system | 1 set |

| Post-cutting device | 1 set |

| Output System | Stacking system | 1 set | 1. Stacker length: 6m. 2. The air source of the system has to be

prepared by customer, with the air pressure higher than 0.5MPa, and

air flow more than 0.5m3/min. The air source shall be dry and clean. |

| Hydraulic System | 1 set | 1. Outside-placed hydraulic station for main machine. 2.

Inside-placed hydraulic station for decoiler. |

| Electric Control System | 1 set | 1. PLC Control. 2. Operation mode: touch screen and buttons. 3.

Speed adjusting: AC frequency conversion. |

Working Process

Decoiling → Feeding → Roll forming → Cutting to length → Finished

panel stacking

Component Description and Parameter

A. Decoiler (JK6-1250AM)

1. Functions and components

| Coil support Type | Decoiling Type | Expanding Type | Press Arm | Coil Car | Hydraulic System | Remark |

| Cantilever | Electrical motor | Hydraulic slide block | No | Yes | Separated | |

2. Parameter

| Max. loading capacity (ton) | 6 |

| Coil ID (mm) | φ508 / φ610 |

| Coil OD (mm) | < φ1300 |

| Material (mm) | 1000-1250 |

3. Main structure and features

1) Machine frame adopts welding structure with shot blasting

treatment.

2) Driven by hydraulic cylinder, the sliding parts can increase or

decrease the inner diameter of the mandrel to tighten the coil.

3) The control box, hydraulic station, reducer and transducer are

mounted inside the decoiler frame.

B. Roll forming system

1. Guiding device

The guiding device uses guiding bar and sliding block to control

the width and position of the steel sheet. The sheet is guided to

the right position and moves to the roll forming equipment. The

transverse position of the guiding device can be adjusted by screw.

2. Roll forming device

Roll forming device consists of machine frame, transmission parts

and roll forming rollers, etc.

1) Machine frame adopts welding structure with shot blasting

treatment.

2) Rollers are made of high quality 38CrMoAl with nitride treated

surface. These rollers with excellent rigidity contribute to

high-precision steel profile.

3) Inner support structure of roller: column.

4) Back/forward movement of roller is driven by chain, and part of

the upward/downward movement is driven by gear.

5) Manually adjust the screw bar to adjust the distance between

upper and lower rollers for sheets with different thicknesses. The

accuracy of finished panel may be fluctuant using raw materials

with different thicknesses.

3. Cutting device after rollforming

1) Cutting blade material: Cr12, quenching treated.

2) Welded frame for good rigidity.

3) The power of cutting is supplied by the hydraulic station.

C. Stacking system

1) Stacker length: 6m.

2) The air source of the system has to be prepared by customer,

with the air pressure higher than 0.5MPa, and air flow more than

0.5m3/min. The air source shall be dry and clean.

D. Electric control system

1. PLC control and frequency speed adjustment help realize

automatic production.

2. Human and machine interface facilitates the setting of plate

length, quantity, etc.

3. Operation mode: touch screen and buttons.

4. Main parts: Mitsubishi.

E. Hydraulic system

1. Decoiler and main machine use separated hydraulic station.

2. Main valve: well-known Shanghai Lixin brand.