Cangzhou Best Machinery Co., Ltd |

|

Verified Suppliers

|

|

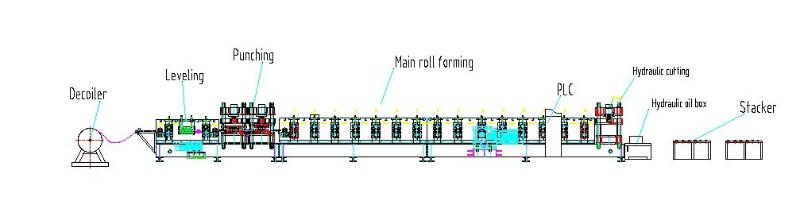

2. Working flow:

Uncoiler—Feeding—Leveling---Hole punching—Roll forming----Hydraulic cut to length—Output table

3. Main component:

1) Decoiler

Hydraulic de-coiler

Single unrolling machine, one side can put material

Adopt automatic hydraulic system

Coil weight (Max): 5000kg

Coil dia (Max): 1600mm

Oil cylinder dia: 1200mm working pressure: 10mpa

Coil Width (Max.): 500mm

Working speed: 0-25m/min

Power: 5.5KW

2) Feeding and leveling system

Feed the coil into to guide wheel (can right and left adjust)

Leveling is three roller above and four roller below, quenched and chrome coated 0.05mm

3) Punching system(adjustable)

Hydraulic punching

Oil cylinder dia: 140mm

Working pressure: 20mpa

Mould material: Cr12 quenched 58°-62°

Hydraulic power: 7.5kw

4) Roll forming machine

Main motor power: 45kw

Total weight: About 15tons

Drive: Gearbox driving with universal joint

Main shaft dia: 100mm material: 45 forge steel

Roller material: GCR15 quenched 58°-62°,chrome coated 0.05mm

Roll station:16stations

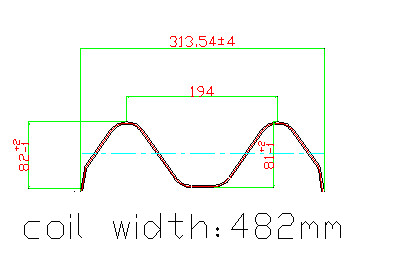

Raw material: Black steel and galvanized steel, thickness: 2.5-3mm

Working speed: 6m--14m/min(Exclude punching time)

PLC: Panasonic, made in Japan 380V 50HZ

Computer operating panel: Touching screen

5) Cutting system

Hydraulic cutting

Blade material: Cr12,quenched 58°-62°

Oil cylinder dia: 250mm

Working pressure: 30mpa