Cangzhou Best Machinery Co., Ltd |

|

Verified Suppliers

|

|

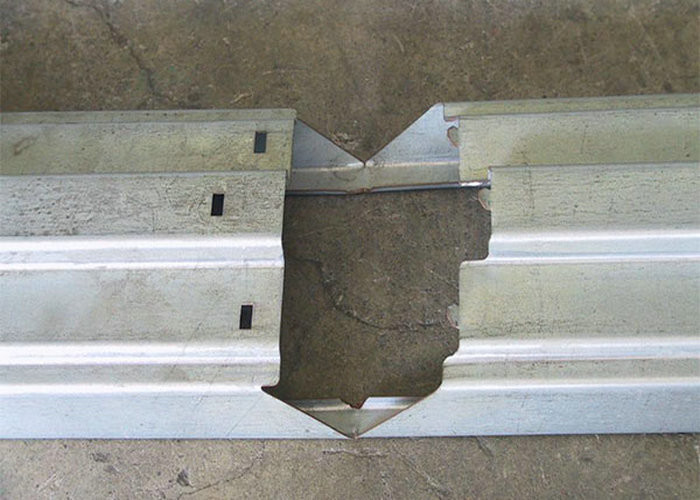

Galvanized Steel Roller Shutter Door Window Frame Roll Forming Machine

Working flow

Decoiler---------leveling--------punching---------roll

forming--------cut to length----------output table

Machine components:

| No. | Name | Qty. |

| 1 | Decoiler | 1set |

| 2 | Feeding and guiding device | 1set |

| 3 | Roll forming machine | 1set |

| 4 | Punching machine with servo feeding | 1set |

| 5 | Hydraulic cutting device | 1set |

| 6 | PLC control box | 1set |

| 7 | output table | 1set |

Techincal description:

A Manual decoiler

(1)Inner Diameter: Φ450 – Φ550 mm

(2)Out Diameter: 1500 mm

(3)Max. Loading Capacity: 3000 kg

B. Main roll forming

1. Number of forming groups: | 18 groups |

2. The machine material: | welding comprise of 12 square tube |

3. The wallboard: | processing compose of 25mm steel plate |

4.The mold: | The mold is made of Gcr12mov steel, processed after rough turning,

finish turning, finish grinding, hard chrome plating to ensure that

the mold no deformation, glabrous, wearable and accurate. |

5.The shaft: | The shaft is made of 45#steel, diameter of 58mm, finish turning,

finish grinding after heat treatment, quenching and high

temperature tempering. |

6. The bearing: | Harbin type 6209 |

7. The rolling material: | 0.7-1.0mm galvanized steel sheet. |

8. Motor: | 7.5kw * 1 set (380v) |

9. Transmission: | 1.5 inch chain |

10. Discharge rack: | 1 set |

11. Machine feature: | PLC NC frequency electrical boxes, touch screen`s display, the

encoder counting, the length and quantity of the material is

controllable, accuracy with in 1.0mm, automatic hydraulic cut. |

C Cutting device

1)Cutting: Hydraulic cutting

2)Auto cutting when reach the set length.

3)Hydraulic power: 7.5KW

4)Blade material: Cr12,quenched 55°-60°

5)Working pressure:16mpa

6)Cutting tolerance: +/- 1.5mm

D Punching

1) Hydraulic punching AFTER roll forming

2) Power:7.5kw

E Control system

(1) Electrical Control: PLC Frequency Control System with touch screen

(2) Voltage: 380V/3Ph/50Hz(or as your local standard)

(3) Length Error: ±1mm

F. Output Table

(1) It is simple and used to load finished product

(2) Length: 4m

Re-sale Service :

1. Send you invitation letter, if you want to visit our factory and

check the machines.

2. Good Quality + Competitive price + Quick Response + Reliable

Service.

Selling Service :

1. Email the production schedule and make prompt delivery.

2. Count the cheapest shipping cost, look for the fastest forwarder

and send relevant documents promptly.

3. Be here for your service at any time.

After-sale Service :

Any questions, contact us by WhatsApp or Telephone.