Cangzhou Best Machinery Co., Ltd |

|

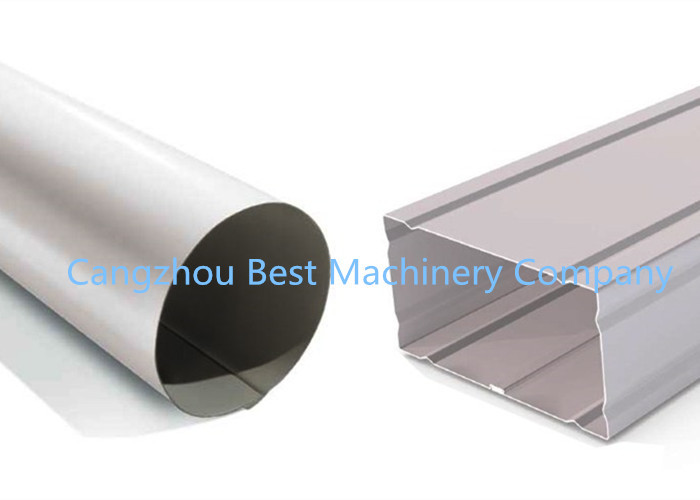

Machine components

De-coiler------------------------------------------1set

Forming machine--------------------------------1set

Cutting device -----------------------------------1set

PLC control box ---------------------------------1set

Hydraulic pump station-------------------------1set

Production support table-----------------------1set

Bending machine---------------------------------1set

SPECIFICATIONS FOR ROLL FORMING MACHINE | |||

Main roll forming machine | Material of roller | High grade 45# forged steel plated with hard chrome plating | |

Working Speed | m/min | 8-15 | |

roller stations | station | 16 | |

Motor power | Main motor power | kw | 5.5 |

Hydraulic Station Power | kw | 3 | |

Hydraulic Station Pressure | Mpa | 12 | |

Otehrs | Electrical Control System | PLC brand | Panasonic Japan |

Material Thickness | mm | 0.25-0.8mm | |

Cutting accuracy | mm | ±2 | |

Machine Parts

Name: Rollers

In order to get high quality product, our machine adopts welded

steel frame structure, AC frequency conversion motor reducer drive,

chain transmission, roller surfaces polishing, hard plating, heat

treatment and chrome coating.

Roller chrome coated thickness: 0.05 mm

Roller material: Forging Steel 45# heat treatment, coated

Main Features

Name:PLC

Brand: Panasonic Japan

Panasonic PLC is adopted to organize all actions of the machine.

The length of workpiece is adjustable according to the setting of

on the PLC. Two optional control modes: automatic and manual. By

automatic mode, the machine can realize fully automatic working. In

order to make the machine has a long service life and easy

maintenance; we only adopt globally famous electrical components.

And by our special designed program, the human-computer interface

is very easy to be adopted by any level of operators.

Brand:China

It is derived by a Gear Pump. After filling the hydraulic oil into

the hydraulic oil tank, the pump could drive the hydraulic cylinder

to realize the cutting function.

The system includes a set of hydraulic tank, a set of a Gear Pump,

two hydraulic pipes .and two sets of Solenoid Valves.

Power of The Pump:4kw

Hydraulic oil :40#

Main Features

Name: Encoder

Brand:OMRON

We understand that the encoder is a very important part of the

cutting to length system, so we only adopt the best quality from

OMRON Japen. And we offer enough matching couplings to make the

machine will never shut off due to the encoder problem.