Cangzhou Best Machinery Co., Ltd |

|

Decoiler

(1) Max. Width: 1000 mm

(2) Inner Diameter: Φ508 – Φ610 mm

(3) Out Diameter: 1500 mm

(4) Max. Loading Capacity: 5000 kgs

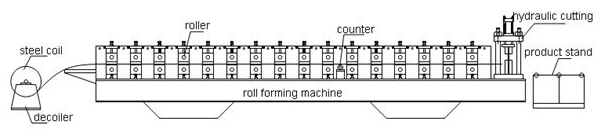

Working flow

Machine components

| No. | Name | Qty |

| 1. | De-coiler | 1 Set |

| 2. | Roll Forming Machine | 1 Set |

| 3. | Hydraulic Cutting Device | 1 Set |

| 4. | PLC Control Box | 1 Set |

| 5. | Hydraulic Pump | 1 Set |

| 6. | Output table | 1 Set |

roll forming

| Item | Parameter detail | ||||||||

| Processing Material | GI and PPGI | ||||||||

| Material thickness | 0.25-0.8mm | ||||||||

| Machine frame | 360#H steel, Adopt diagonal line welding, leveling instrument measurement to make sure the final frame is high-precision | ||||||||

| Machine siding panel |

| ||||||||

| Forming stations | 13-22 stations(according to the profiles) | ||||||||

| Machine rollers | high grade No.45 forged steel,plated hard chroming with thickness

0.05mm | ||||||||

| Machine Shaft | φ70-80mm high garde No.45 steel after treatment, | ||||||||

| Machine spacers | CNC lathing in high-precision | ||||||||

| Machine bearings | China Haerbin bearing or SKF international bearing(option) | ||||||||

| Driving system | 1 inch chain or gear box(option) | ||||||||

| Machine power | 3kw-11kw(according to the profiles) | ||||||||

| Machine working speed | 8-12m/min or 10-30m/min(option) | ||||||||

| Machine adjust type | After machine installation, we will test it ourselves, compare with the profile drawing, the difference is controlled in 0.5mm |

Cutting

| Type | bearing sliding type |

| Blade material | Cr12mov quenching and grinding |

| Frame processing | the whole bottom frame is grinding for high-precision |

| Blade processing | wire-electrode cutting, but the upper balde can not be straight. this is technology |

| Working | Hydraulic type |

Stacker

| Type | Manual | |

| Length | 1.5m-2m | 6m or 12m |

PLC

| Main item | Parameter detail |

| PLC | Delta(standard) or according to your request |

| Inverter | China brand(standard) or according to your request |

| Touch screen | Mcgs(standard) or according to your request |

| Encoder | China brand(standard) or according to your request |

| Voltage/HZ/Phase | 380v/50-60hz/3phase |

Installation and training: If buyers visit our factory and check the machine, we will teach

you how to install and use the machine, and also train your

workers/technician face to face.Without visiting,we willsend you

user manual andvideo to teach you to install and operate.If buyer

needs our technician to go to your local factory,please arrange

board and lodging and other necessary