Sussman Machinery(Wuxi) Co.,Ltd |

|

Verified Suppliers

|

|

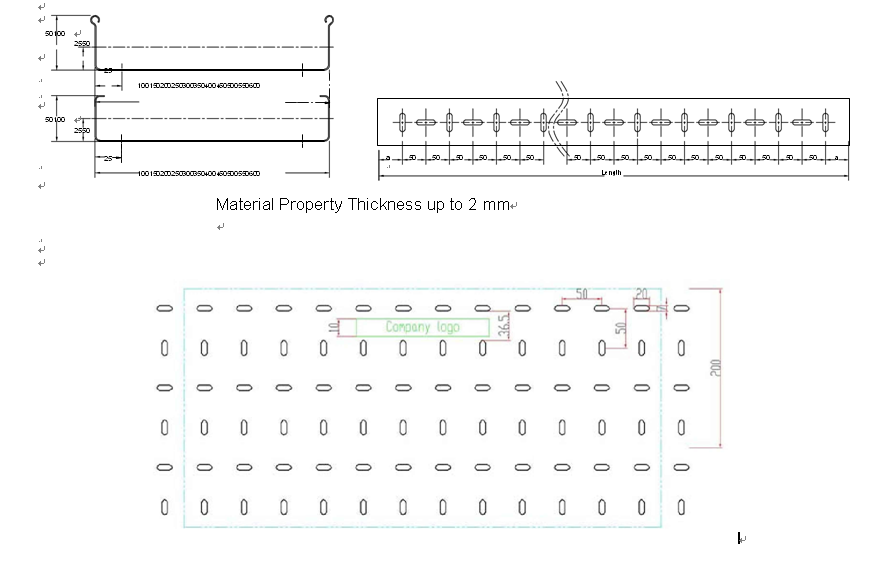

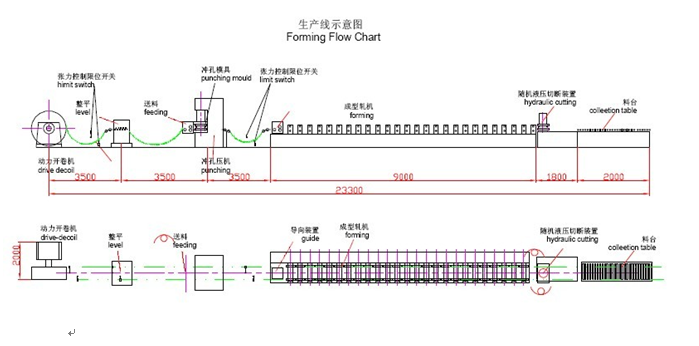

Machine process

Decoiler- leveling—servofeeding---Punching Press--Roll forming-Cutting-Outtable

Used sheet steel materials for cable tray product are:

DX51 EN10142(1991) – thickness: 1-2mm

Profiles according to the customer’s request

To make the 2 profiles by change spacers, and adjust the width by automatically

Machine Layout

5 ton hydraulic De-coiler

Diameter: 508-610mm Hydraulic expansion. Pictures for reference

Expansion: hydraulic decoiler

Capacity: 5000kg per mandrel

Max Coil Width: 1250mm

Drag tension brake with variable brake tension adjustment valve

Leveling device

7 rolls leveling, 3 rolls up and 4 rolls down

Diameter is Ø 80mm, chrome and HRC60 heat treatment to secure the smooth surface

Leveling Raw Material thickness:1.0-2mm

Max Leveling Raw Material width: 1000mm

Power: 7.5kw

idi-font-family:Arial;line-height:150%;font-size:9.0000pt;mso-font-kerning:1.0000pt;" >1250mm

Drag tension brake with variable brake tension adjustment valve

Feeding device

Feeding Servo feeding motor: about 7.5KW,Yaskawa(Japanese Brand)

Description: servo feeding can control the punching distance in precision, controlled by PLC, and the feeding tolerance can be+-0.05mm, the servo motor can control the speed, and can accept the input signal, and react quickly, and performance well, the touch screen can display the rotating speed, the length and the quantity, it can be controlled by the manual and auto modes.

Press machine

Series JH21-200B

Brand name: Yangli

JH21 series press machine description:

JH21series open back press with dry clutch and hydraulic overload protector

◆ Welded body with steel plate and high intensity.

◆ Main motor is made by Siemens.

◆ Adopts combined pneumatic friction clutch and brake.

◆ Cluster gear adopts the flooding oil lubrication.

◆ Six-face rectangle lengthen guide; JH21-315B/400B adopts eight-face lengthen guideway.

◆ Equipped with hydraulic overload protecting device.

◆ JH315 adopts manual shut height adjustment, Among these types JH21-25/45 adopts scale display and JH21-25B with digital display.JH21-250 and above type adopts electric shut height adjustment with digital display.

◆ JH21-180 can equip with die set height adjustment motor, the value will be displayed by digital. above type equipped with balance cylinder.

◆ Duplex valves imported.

◆ Electric compelling grease lubrication system.

◆ Balancing cylinder adopts manual lubrication system.

◆ One set of blowing device.

◆ Controlled by PLC with international brand.

◆ Buttons, indicators, AC contactors, air circuit breakers and other controlling devices are imported from international brand.

◆ Equipped with optional air cushion device, automatic feed shaft and photoelectric protector,which can used to work with various automatic equipments.

Punching Moulds description

As for the profiles, total need 5 sets of punching moulds, when need to punching the first hole drawing, change the punching mould 1, when punching the second hole drawing, change the punching mould 2, ect. When the punching heads broke, they can be removed, and changed by the new punching heads.

Punching moulds material: Cr12Mov Quenching HRC58-62degree Shanghai NO.5 Steel (China best brand for steel)

Punching holes: long holes at bottom 35*7, and distance is 25mm, and 80mm. with Logo

Side holes: when width is 50mm, 2 holes, when width is 100mm, 2 holes, and when width is 150mm, 3 holes.

7.Product drawing

8.FAQ

1) Q: Are you manufacturer or trading company?

A: We are manufacturer and trading company .

2) Q: Do you provide installing and training overseas?

A: Overseas machine install and worker training services are

optional.

3) Q: How is your after sales support?

A: We provide technical support on line as well as overseas

services by skillful technicians.

4) Q: How does your factory do regarding quality control?

A: There is no tolerance regarding quality control. Quality control

complies with ISO9001. Every machine has to past testing running

before it's packed for shipment.

5) How can I trust you that machines pasted testing running before

shipping?

A: 1) We record the testing video for your reference. Or,

2) We welcome your visit us and test machine by yourself in our

factory.

6) Q: Do you sell only standard machines?

A: No. Most machines are made to order.