Sussman Machinery(Wuxi) Co.,Ltd |

|

Verified Suppliers

|

|

GCr15 Steel Sheet CZ Purlin Interchangeable Roll Former Machine

With Per Cutting

One machine can produce differenct C/Z Purlins throught simple

manual stepless adjustment, when to produce different profiles, no

need to change the forming rollers. In the process, machine adopt

automactic control model, it can auto pumch, cut, forming based on

inputting length of purlin, portrait hole distance, quantity, etc

datas.

C/Z purlin roll former make up of decoiler, feeding, leveling, 2

sets hydraulic punching device, hydraulic cutting, speediness

interchangeable forming machine, PLC control system, hydraulic

stations, runout tables.

It is quick and easy to operate the machine, and beautiful

appearance, high production efficiency, forming speed up to

15m/min.

This kind of machine can produce C , Z two profiles, through the

exchange side of the roller up and down position to achieve C , Z

purlin conversion , just need about half an hour to achieve saving

time. This machine also can automatically adjust roller horizontal

distance to achieve C or Z purlins pf the width with high precision

, but also save time to increase production.

C Z Purlin Technical Parameter

| Item | Parameter | |

| Material thickness | 1.0-3.0mm Steel sheet | |

Steel coil width | 200-600mm | |

| Size of purlin | 80-350mm | |

Power | Voltage | 380V/3PH/50HZ |

| Main Motor | 11kw | |

| Hydraulic motor | 7.5kw | |

| Hydraulic pressure | 10-12MPa | |

| Main forming stations | 18 steps |

| Forming Shaft | diameter 75 mm, 45# steel thermal refining | |

| Roller Material | GCR15 bearing steel | |

| Blade material | Cr12 mould steel with quenched treatment 60-62° | |

| Punch Mould (if needed) | Cr12 quenched | |

| Forming Speed | 0-15m/min | |

| Cutting system | Length-set cutting after roll formed | |

| Control System | PLC and Inverter | |

Main Components

Decoiler 1 set

Levelling device 1 unit

Punching device 1 unit

Main roll forming machine 1 set

Hydraulic station 1 set

Hydraulic cutting 1 set

Control system 1 set

Run out table 2 units

Working Flow

Decoiler—feeding with guide—leveling—hydraulic punching—cutting—

roll forming—runout table

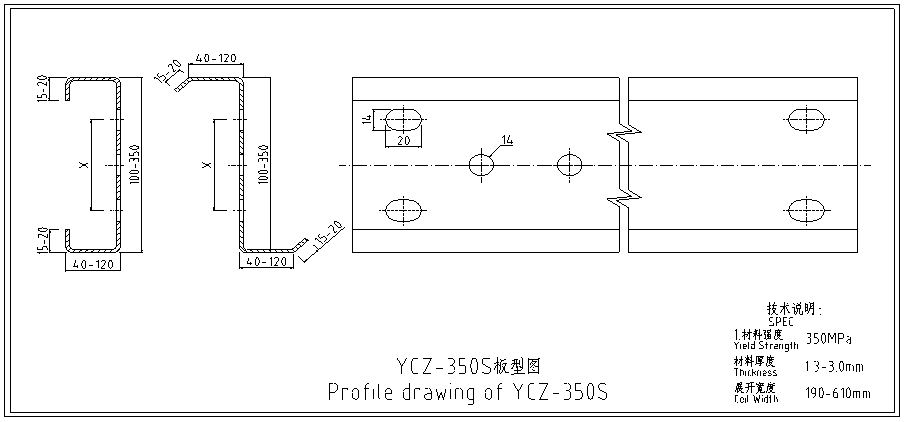

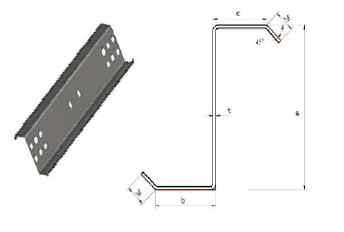

Profile and Drawing Of Product

Packaging & Shipping

Packaging: Main body of machine is naked and covered by

plastic film,loaded into container with steel rope and lock catch

suitable for long-distance transportation, spare parts are covered

by plastic film.

Delivery Time:75 days.

Our Service

Warranty: 1 year warranty from date of shipment.

Guarantee:

1: Guaranteed against malfunctions due to manufacturing defects for

1 year after date of purchase. Repairs will be made free of charge.

2: Repairs will not be performed free of change even during the

guarantee period in the follow circumstances

- Damage occurs due to a natural disaster

- Malfunction occurs due to user error

- Malfunction occurs due to modifications

- Malfunction occurs due to further movement or shipment after

installation.