Qingdao Ruly Steel Engineering Co.,Ltd |

|

Verified Suppliers

|

|

Customized Steel Structure Building For Prefabricated Pet Feed Processing Factory

A steel structure pet food processing factory is a facility specifically designed for the production and packaging of pet food products. The use of steel as the primary construction material ensures a robust and durable structure that can accommodate the unique requirements of the manufacturing process.

The exterior of the factory features a steel framework, providing structural integrity and stability. The steel construction allows for the incorporation of large windows and entrances, facilitating natural light and easy access for deliveries and shipments.

Inside the factory, the steel structure provides a spacious and open layout, allowing for efficient workflow and equipment installation. The production area consists of various sections, including raw material storage, processing lines, mixing and blending stations, extrusion or cooking equipment, drying systems, and packaging lines. The steel framework supports heavy machinery and equipment, ensuring a safe and stable working environment.

The raw material storage area is designed to accommodate bulk ingredients such as grains, meat, vegetables, and supplements. The steel structure allows for the installation of storage bins, silos, and conveyor systems, facilitating the efficient handling and transfer of raw materials to the production lines.

The processing lines consist of specialized equipment for grinding, mixing, and blending the raw materials. The steel structure supports the installation of these machines, ensuring stability and minimizing vibration during the production process. The processing lines are designed to meet stringent hygiene standards, with stainless steel surfaces that are easy to clean and maintain.

In the cooking or extrusion area, the steel structure supports high-temperature equipment such as ovens or extruders used to cook or process the pet food mixture. The steel framework ensures the safe operation of these heat-intensive processes, providing a stable and secure environment.

After cooking, the drying systems utilize the steel structure to accommodate large-scale drying chambers or conveyor belts. These systems remove moisture from the pet food while maintaining nutritional value and extending shelf life.

The packaging lines are designed for efficient and automated packaging of the finished pet food products. The steel structure supports conveyor systems, packaging machines, and storage areas for packaging materials. This allows for smooth and streamlined packaging operations, ensuring the timely and accurate packaging of the pet food products.

Throughout the factory, the steel structure allows for the integration of essential utilities such as ventilation systems, lighting fixtures, and electrical wiring. These systems ensure a comfortable and safe working environment for employees while maintaining the necessary conditions for pet food production.

In summary, a steel structure pet food processing factory provides a robust and efficient facility for the production and packaging of pet food products. The steel construction enables the seamless integration of specialized equipment, efficient workflow, and adherence to strict hygiene standards, ensuring the production of high-quality pet food for the market.

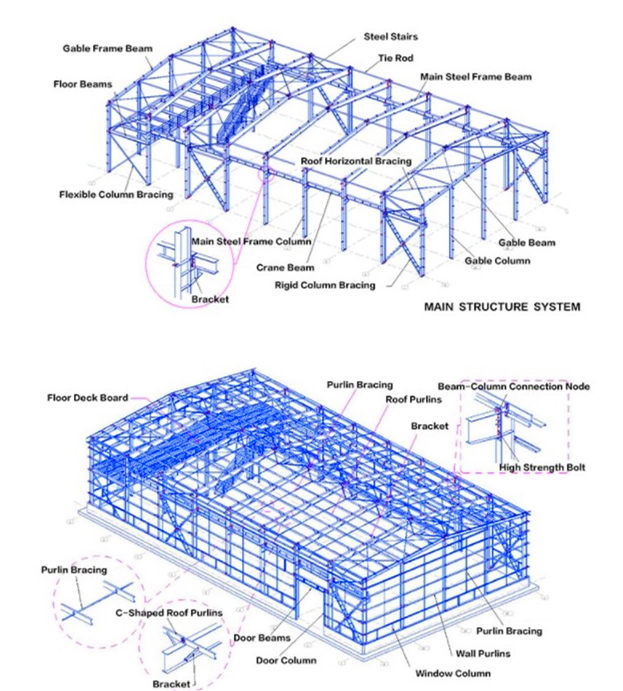

| Main Steel Frame System | |

| Main structure | H section steel Q355, alkyd painting, two primary painting, two finish painting. |

| Roof purlin | XZ160*60*20*2.5, galvanized |

| Wall purlin | XZ160*60*20*2.5, galvanized |

| Intensive bolt | Grade 10.9 |

| Turn buckle bolt | M20+2, steel Q235, processing |

| Anchor bolt | M24, steel Q235, processing |

| Ordinary bolt | Galvanized bolt M20 |

| Ordinary bolt | Galvanized bolt M12 |

| Brace nut | Galvanized bolt M12 |

| Bracing System | |

| Cross brace | Φ20 round steel bar Q235, process and painted (alkyd painting) |

| Angle brace | L50*5 angle steel Q235, process and painted (alkyd painting) |

| Column bracing | Φ25 round steel bar Q235, process and painted (alkyd painting) |

| Tie bar | Φ127*3 steel pipe Q235, process and painted (alkyd painting) |

| Batter brace | Φ32*2.5, Φ12 round steel bar Q235, process and painted (alkyd painting) |

| Wall & Roof System | |

| Roof panel | Corrugated steel plate or sandwich panel (EPS/fiber glass/rock wool/PU) |

| Wall panel | Corrugated steel plate or sandwich panel (EPS/fiber glass/rock wool/PU) |

| Edge cover | 0.5mm color plate, angle Alu. |

| Fittings & accessories | Nails, glue etc. |

| Unpowered ventilator | Diameter Φ600, stainless steel |

| Sky lighting band | 1.2mm FRP, double layer |

| Sliding door | sandwich panel door |

| Roof drainage system | |

| Gutter | 0.5mm color steel plate |

| Rainspout pipes | Φ110 PVC pipe |

Qingdao Ruly Steel Engineering Co., Ltd is a professional steel

structure design, research, fabrication and construction company,

located in Qingdao, China. Our company's steel structure processing

plant now covers an area of 35, 000 square meters, plant20, 000

square meters. More than 100 employees. The monthly production

capacity for steel structure is more than 2000 Tons.

We could contract the projects such as prefabricated steel

structure warehouse, workshop, storage sheds, garage, hangar,

chicken shed, car parking, showroom, office buildings, gym,

dormitory building, high rise steel residence buildings,

oli&gas project, power station, infrastructure buildings, etc.

At present, Our products have been exported to Southeast Asia,

South America, Middle East and Africa, Australia, etc. In order to

serve better for the exported project, we get certification of AWS

D1.1, CE(EN 1090-1: 2009+A1: 2011), ISO 14001, ISO9001, ISO45001,

AS/NZS 1554, SGS and BV Certification.

We provide one-stop service for steel structure project, just tell

us your requirement, and we will give you what you need.

All the structure components, panels,bolts and sort of accessories will bewell packed with standard package suitable ocean transportation and loaded into 40'HQ.

All the products are loaded at the loading site of our factory using crane and forklift by our skilled workers,who will prevent the goods to be damaged.

1. Professional design team, we could design the drawing as your requirement or calculate the steel quantity based on your drawing.

2. Skilled fabrication team and advanced equipment. We make the independent production schedule to each project.

3. One-stop service: We have completed lots such kinds of projects, we could provide the integrated proposal for your project.

4. Professional QC team will guarantee that we will provide the production and service as your request.

5. After sales service: If it has any questions that need us to do in your process of using, such as the maintain of outside insulation and steel components, just tell us , we will try to provide the service as well as we can.

The following questions we need to know before offering the quotation. Just feel free to fill in what you know.

| 1 | Location (where will it be built?) | _____country, area |

| 2 | Size: length*width*height | _____mm*_____mm*_____mm |

| 3 | wind load (max. wind speed) | _____kn/m2, _____km/h, _____m/s |

| 4 | snow load (max. snow height) | _____kn/m2, _____mm |

| 5 | anti-earthquake | _____level |

| 6 | brickwall needed or not | If yes, 1.2m high or 1.5m high |

| 7 | thermal insulation | If yes, EPS, fiberglass wool, rockwool, PU sandwich panels will be

suggested; . if not, the metal steel sheets will be ok. The cost of

the latter will be much lower than that of the former |

| 8 | door quantity & size | _____units, _____(width)mm*_____(height)mm |

| 9 | window quanity & size | _____units, _____(width)mm*_____(height)mm |

| 10 | crane needed or not | If yes, _____units, max. lifting weight____tons; max. lifting height _____m |