Shandong Longkuang Metal Products Co., Ltd. |

|

Verified Suppliers

|

|

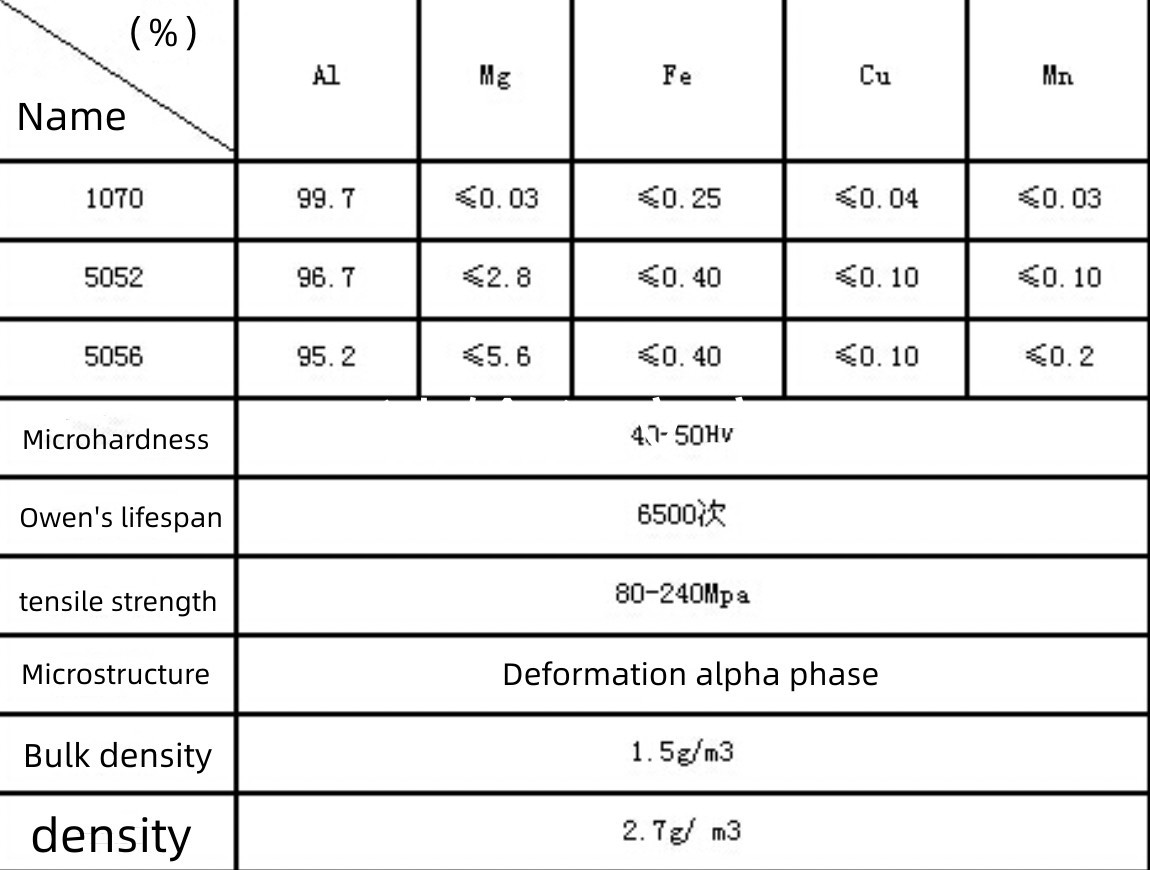

Non-Flammable Aluminum Shot High Corrosion Resistance And Tensile Strength 80-240MPa

Aluminum shot, also known as aluminum wire cut shot, aluminum wire grinding shot, aluminum grit, aluminum pellets, etc., is produced through processes such as wire drawing, cutting, and grinding.

Characteristics:

Bright appearance

Lightweight compared to other abrasives

Low hardness

Corrosion-resistant

Allows for polishing without damaging the surface of the product

Provides significant whitening effect on the workpiece surface

Product specifications:

Size: 0.2mm-3.0mm

Enhanced portability: Aluminum shot's exceptional lightweight nature makes it highly portable, facilitating ease of transportation and handling. This attribute is particularly advantageous in applications where mobility and maneuverability are crucial, such as in remote or on-site surface preparation tasks.

Non-sparking properties: Being non-ferrous and non-magnetic, aluminum shot offers the advantage of being non-sparking. This makes it suitable for use in environments where the generation of sparks poses safety risks, especially in industries dealing with flammable or explosive materials.

Gentle abrasion: Aluminum shot's lower density and softer impact provide a gentler abrasion process on the workpiece surface. This characteristic is beneficial when working with delicate materials or components that require a more delicate touch, minimizing the risk of damage or surface deformation.

Long-lasting shine: Thanks to its natural oxide layer, aluminum shot retains its shine and visual appeal over time. This attribute is advantageous in applications where long-lasting surface aesthetics are important, ensuring an enduring and attractive finish.

Sustainable material: Aluminum shot is an environmentally sustainable choice due to its high recyclability. Its efficient recovery and reuse contribute to waste reduction, resource conservation, and cost-effectiveness, aligning with environmentally friendly manufacturing practices.

Minimal airborne contaminants: Aluminum shot's low dust generation during the cleaning process ensures a cleaner working environment. This is particularly valuable in industries where airborne dust needs to be minimized, such as cleanroom environments or sectors with strict air quality regulations, ensuring optimal working conditions and product quality.

Surface protection for delicate materials: With its lower density and softer impact, aluminum shot provides surface protection when working with delicate or sensitive materials. It allows for surface cleaning and preparation without causing damage or deformation, preserving the integrity and quality of the treated materials.

| Parameter | Value |

|---|---|

| Product Name | Metallic Aluminum Shot |

| Usage | Surface Blasting Treatment |

| Tensile Strength | 80-240MPa |

| Density | 2.7g/cm3 |

| Malleability | High |

| Flammability | Non-flammable |

| Conductivity | High |

| Owen's Lifespan | 6500 times |

| Corrosion Resistance | High |

| Uses | Shot Blasting, Metal Additive, Fireworks |

| Material | Aluminum |

| Key Features | Metallic aluminum granules, Metallic aluminum shot, Metallic aluminum granules for shot blasting |

Surface rejuvenation and corrosion mitigation: Aluminum shot is effective in rejuvenating surfaces and mitigating corrosion by removing oxidation layers, rust, oil residues, and other contaminants from workpiece surfaces. It ensures a clean substrate for subsequent coating, welding, or machining processes, enhancing the overall longevity and performance of the treated surfaces.

Surface refinement and luster enhancement: Aluminum shot is utilized for surface refinement and luster enhancement, improving the quality and appearance of workpieces. It removes burrs, dents, and defects, resulting in a smoother, more uniform surface with enhanced glossiness, adding aesthetic value to the treated workpieces.

Maintenance of compression molding and stamping dies: Aluminum shot plays a crucial role in maintaining compression molding and stamping dies. It removes carbon deposits, residues, and oxides from the die surfaces, restoring their geometric shape and surface smoothness. This ensures proper functionality, extends their lifespan, and optimizes the quality of the molded or stamped products.

Cleaning and preparation of aluminum workpieces: Aluminum shot is employed to clean and prepare the surfaces of aluminum workpieces. It effectively removes oxidation layers, dirt, and grease, creating a clean and pristine surface for subsequent coating, welding, bonding, or assembly processes. This ensures optimal adhesion, integrity, and performance of the finished products.

Refinement of post-processed 3D printed parts: In the realm of 3D printing, aluminum shot serves as a valuable tool for refining post-processed printed parts. It is adept at removing support structures and residues from the surface, achieving the desired surface quality and preparing the parts for subsequent treatments, coatings, or assemblies, ensuring optimal functionality and aesthetics.

Casting surface preparation and treatment: Aluminum shot is widely employed in casting surface preparation and treatment processes. It efficiently removes sand grains, oxides, and other contaminants from the casting surfaces, ensuring clean and defect-free castings for subsequent heat treatment, coating, or machining operations. This enhances the overall quality and integrity of the castings, resulting in superior performance and durability.

Inner packaging: 25kg/bag with inner film bag.

Outer packaging: nylon woven bag, kraft paper bag, carton.

Whole ton packaging: pallet or ton bag.