Guangdong ABLinox Sanitaryware Co., Ltd. |

|

China Precision Lose Wax Casting Foundry Produce Steel Alloy Investment Casting Fishing Weight Drop Shape

Product Description

| Material | Stainless Steel ,316 316L 2205 |

| Processing | lost wax casting process + Precision CNC Machining + Surface Treatment |

| Casting process | Client drawings , pattern, raw casting, machining, packing and delivery |

| Surface treatment | Plating, anodizing powder coating, spray-paint, electrophoresis |

| Size | Customized as customer's drawings |

| Standards | DIN, AISI, ASTM, BS, JIS, etc |

| Service | To chart to sample production; OEM / ODM |

| Certificate | ISO9001:2015 |

| MOQ | Small order is acceptable |

| Shipping | Accept FOB or customer designated shipping agent |

| Package details | Standard export package(carton/wooden case/pallet) |

| Application | Fishing weight,foodstuff, power, construction, etc. |

Main products

| Pipe fittings |

| Bar fittings |

| Hrandrail fittings |

| Glass Clamp/Glass Spigot |

| Spider |

| commercial/industrial kitchen equipment |

| Marin Hardware |

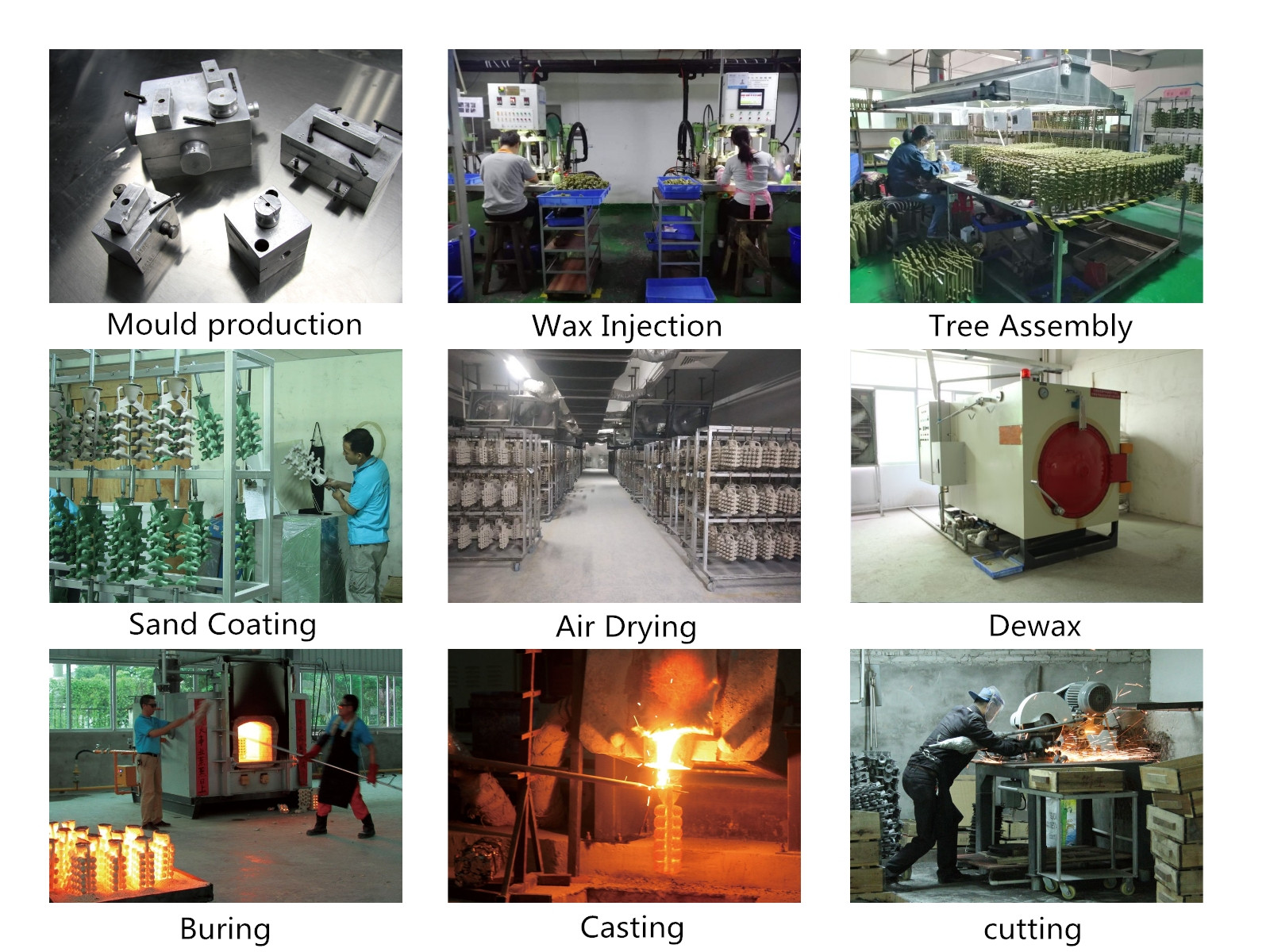

Production Process

1. TOOL MAKING

A wax injection mold is designed and built to produce castings per

customer specifications.

2. WAX PRODUCTION

A wax pattern is produced from the wax injection mold.

3. PATTERN ASSEMBLY

Wax patterns are attached to gating system by hot knife.

4. SHELL MAKING

The pattern assembly is dipped into a ceramic slurry, coated with a

refractory material and dried. The process is repeated until the

desired thickness and strength is achieved.

5. DEWAXING

Using regulated steam pressure, an autoclave melts and remove the

wax from the ceramic shells.

6. SHELL PREHEAT

High temperature ovens cure and preheat the ceramic shells before

pouring.

7. CASTING

Pre-heated Ceramic cavities are poured with the molten metal.

8. KNOCK OUT

The ceramic shell is removed by vibration knocking and the cluster

is cleaned.

9. CUT OFF

Castings are cut off from the gating system.

10. MACHINING,SURFACE FINISH,AND INSPECTION

After cut off and gate removal, all secondary finishing operations

are performed. Each casting is inspected according to customer

specifications and requirements.

Equipments

We specialize in turning, drilling, tapping, and a variety of other machining capabilities to offer a complete product.

With these in-house turning capabilities,We also can quote your bar stock requirements, which complements

our investment casting line.

ABLinox can be your one-stop-shop and has in-house machining capabilities as well as outside machining services available for specialized machining.

ABLinox specializes in turning, drilling, tapping, and a variety of other machining capabilities to offer a complete product With these in-house turning capabilities, ABLinox also can meet your ready assembly product price requirements,which complements our investment casting line.

ABLinox wants to become a high-end customized expert in stainless steel industry.

ABLinox have been cooperated with some TOP 500 enterprises in the world.

ABLinox wants to be your first-grade partner in near future.

Our Service

l OEM & ODM l Mould design l Drawing design l Investment Casting l Heat treatment

l Machining l Surface treatment l Assembly l Packing l Export & Trading to whole world

l Fast response within 24 hours l Project management l After-sales service

Quality inspection at each stage,

1. Incoming material inspection 2. Inspection of work-in-progress

3. Finished product inspection 4. Random warehouse inspections