JIANGSU MITTEL STEEL INDUSTRIAL LIMITED |

|

Verified Suppliers

|

|

AISI 4140 Steel 1.7225 42CrMo4 SCM440 Alloy Steel Round Bar Diameter 10 - 300mm

Products Specification

| Products Name | Steel Round Bar |

| Diameter | 10 - 300mm |

| Length | 6m or custom cutting any length as request |

| Type | Hot Rolled |

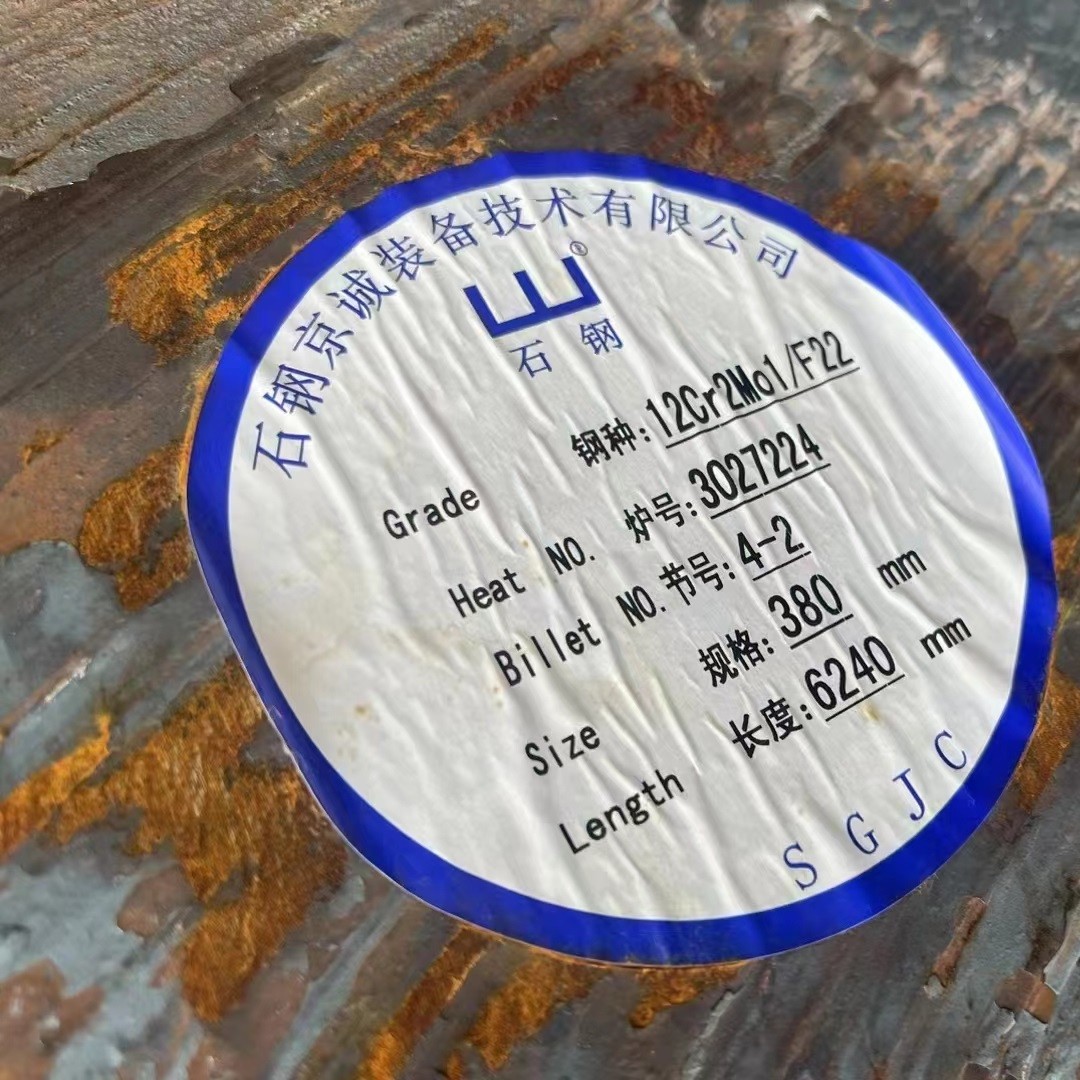

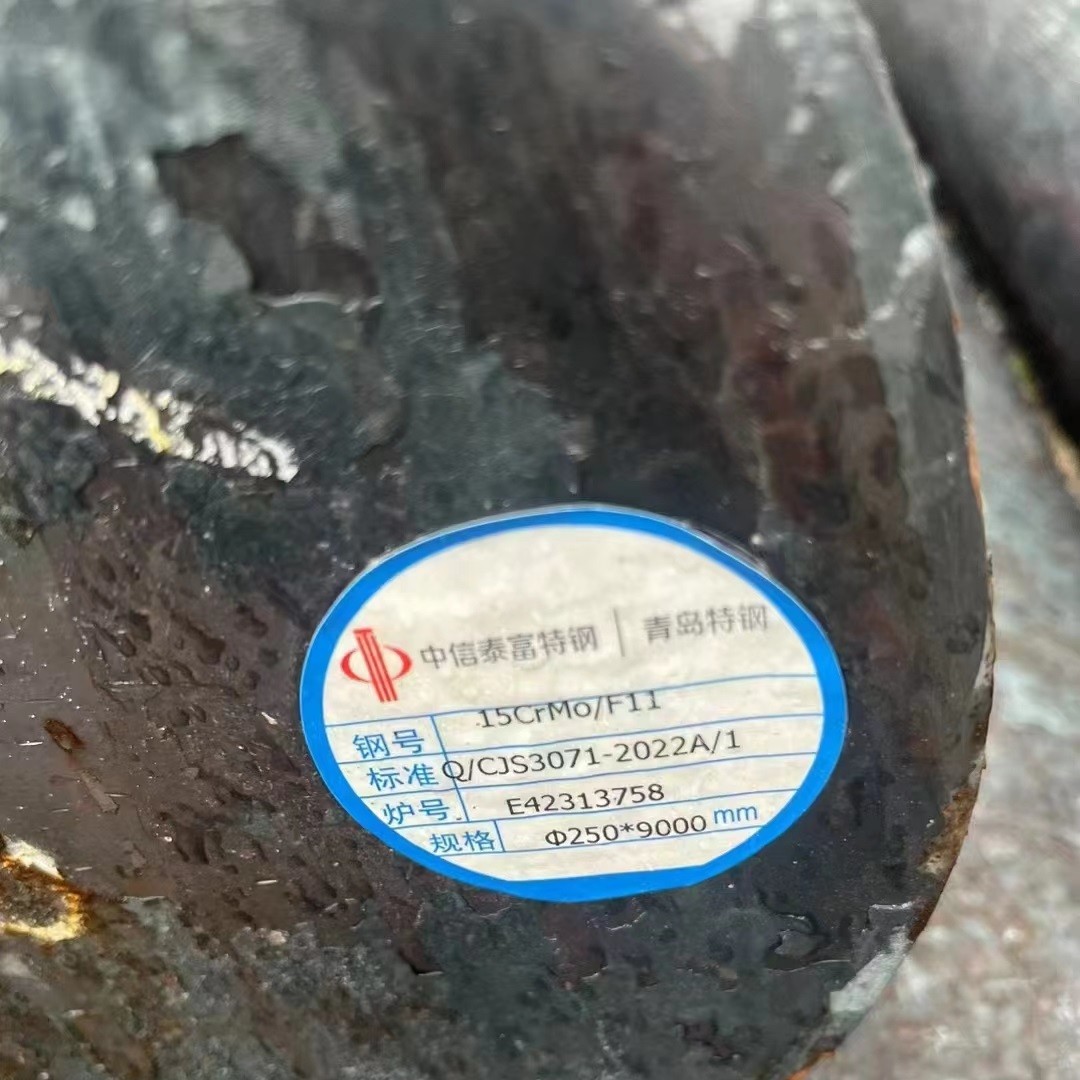

| Brand | BAOSTEEL DELTA DONGBEI HUAXI SHAGANG.etc |

| MOQ | 1 Ton |

| Loading Port | Shanghai Port |

| Packing | packing by steel wire rope |

| Deliver time | 5 - 7 days for stock materials |

| Other Grade | Q195,Q235,10#,20#,35#,45#,Q215,Q345,12Cr1Mov, 15CrMo,304,316,20Cr,40Cr,20CrMo,35CrMo,42CrMo, 40CrNiMo,GCr15,65Mn,50Mn,50Cr,3Cr2W8V,20CrMnTi,5CrMnMo |

| Standard | ASTM GB EN DIN |

| Application | Structure and Industrial |

AISI 4140 Alloy Steel is a common chromium-molybdenum steel that usually used after quenched and tempered, with high intensity, high hardenability. The alloy 4140 plate also has high fatigue strength and good low-temperature impact toughness.

Gnee has great advantage on 4140 steel plate:

When discussing AISI 4140, it is important to understand what the grade number means:

| Number | Meaning |

| 4 | Designates that 4140 steel is molybdenum steel, indicating that it possesses higher amounts of molybdenum than other steels, such as the 1xxx series. |

| 1 | Designates that 4140 steel has additions of chromium as well; more so than 46xx steel for example. |

| 40 | Used to differentiate 4140 Steel from other steels in the 41xx series. |

AISI 4140 is made by placing iron, carbon, and other alloying elements into an electric furnace or oxygen furnace. The major alloying elements added to AISI 4140 are:

Once the iron, carbon, and other alloying elements have been mixed together in liquid form, it is allowed to cool. The steel may then be annealed; possibly several times.

After the annealing is complete, the steel is heated to a molten phase again so that it can be poured into the desired form and can either be hot worked or cold worked through rollers or other tools to reach the desired thickness. Of course, there are other special operations that can be added to this to reduce mill scale or improve mechanical properties.

Mechanical Properties of 4140 SteelAISI 4140 is a low alloy steel. Low alloy steels rely on elements other than just iron and carbon to enhance their mechanical properties. In AISI 4140, additions of chromium, molybdenum, and manganese are used to increase the strength and hardenability of the steel. The additions of chromium and molybdenum are why AISI 4140 is considered a “chromoly” steel.

There are several important mechanical properties of AISI 4140, including:

The table below highlights the chemical composition of AISI 4140:

| C | Cr | Mn | Si | Mo | S | P | Fe |

| 0.38-.43% | 0.80-1.10% | 0.75-1.0% | 0.15-0.30% | 0.15-0.25% | 0.040% max | 0.035% max | Balance |

The addition of chromium and molybdenum promotes corrosion resistance. The molybdenum can be particularly useful when trying to resist corrosion due to chlorides. The manganese in AISI 4140 is used to increase hardenability and as a deoxidizer. In alloy steels, manganese can also combine with sulfur to improve machinability and make the carburizing process more effective.