Shanghai Titanic Steel Co., Ltd. |

|

Verified Suppliers

|

|

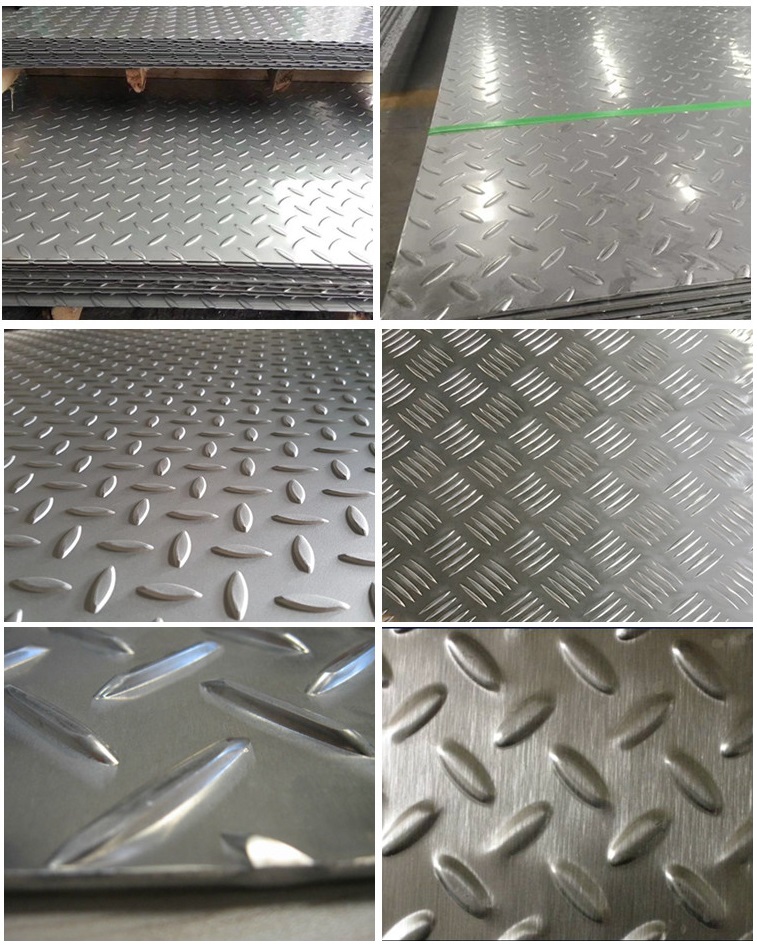

201 Embossed Plate 304 Stainless Steel Checkered Plate Diamond Plate

Our 201 embossed plate and 304 stainless steel checkered plate offer a durable and visually appealing solution for various applications. The embossed plate features a diamond pattern, adding a touch of elegance and texture to any space. Crafted with precision and expertise, these plates provide excellent corrosion resistance and durability. Whether you need them for decorative accents or functional purposes, our embossed and checkered plates offer reliable performance and a sleek appearance. Choose our stainless steel plates for their high-quality construction, attractive design, and versatility in enhancing the aesthetics of any project.

Surface Treatment

Packaging & Shipping

FAQ

Q1: Are you a trading company or manufacturer?

A1: We are a professional manufacturer of steel products, and our company is also a very professional trade company for steel

products. We can also provide a wide range of steel products.

Q2: How long is your delivery time?

A2: Generally it is 5-10 days if the goods are in stock. or it is 15-20 days if the goods are not in stock, it is according to quantity.

Q3: Do you provide samples? Is it free?

A3: The sample could provide for the customer for free, but the courier freight will be covered by the customer account.

Q4: Do you accept third-party inspection?

A4: Yes absolutely we accept.

Q5: How could you guarantee your products?

A5: Each piece of product is manufactured by certified workshops, and inspected by employee piece by piece according to national QA/QC standards.

Q6: How do we trust your company?

A6: We specialize in the steel business for years, you are welcome to investigate in any way.

Q7: Are you a trading company or manufacturer?

A: We are a factory. we welcome customers from all over the world to visit our factory.

Checkered Stainless Steel Plate Product Profile

Checkered stainless steel plates, also known as diamond or tread plates, are specially designed to offer enhanced slip resistance and aesthetic appeal. These plates feature a raised pattern of alternating diamond-shaped projections, providing traction and reducing the risk of accidents in various industrial and architectural applications. This product profile aims to provide a comprehensive overview of checkered stainless steel plates and their key features.

Key Features:

1. Slip Resistance: Checkered stainless steel plates are designed with a raised pattern of diamond-shaped projections. This pattern enhances the grip and provides excellent slip resistance, making them ideal for applications where safety is a priority, such as industrial flooring, staircases, walkways, and transportation platforms.

2. Corrosion Resistance: Checkered stainless steel plates are manufactured from corrosion-resistant stainless steel alloys, such as 304 or 316 stainless steel. This ensures exceptional resistance to rust, oxidation, and chemical corrosion, making them suitable for both indoor and outdoor applications.

3. Durability and Strength: Checkered stainless steel plates offer excellent durability and strength, ensuring long-lasting performance even under heavy loads and harsh conditions. They can withstand mechanical stress, impacts, and abrasion without compromising their structural integrity, making them suitable for high-traffic areas.

4. Easy Maintenance: Checkered stainless steel plates are easy to clean and maintain. The raised pattern minimizes dirt and debris accumulation, making them easy to wash and preventing the growth of bacteria or mold. This feature is particularly advantageous in industries with stringent hygiene requirements, such as food processing or pharmaceutical facilities.

5. Versatility: Checkered stainless steel plates are available in various grades, sizes, and thicknesses to accommodate different application requirements. They can be further processed, cut, or shaped to meet specific design needs, allowing for versatility in architectural and industrial projects.

6. Aesthetic Appeal: In addition to their functional benefits, checkered stainless steel plates also provide an attractive appearance. The raised diamond pattern adds texture and visual interest to surfaces, making them suitable for decorative purposes in architectural applications.

Common Applications:

1. Industrial Flooring: Checkered stainless steel plates are widely used for industrial flooring in factories, warehouses, and production facilities. Their slip-resistant surface helps prevent accidents and improves worker safety, while their corrosion resistance ensures durability in demanding environments.

2. Transportation Platforms: Checkered stainless steel plates find applications in transportation platforms, such as buses, trains, ships, and loading docks. Their slip-resistant surface allows for secure footing, reducing the risk of slips and falls, especially in wet or oily conditions.

3. Architectural and Decorative Applications: Checkered stainless steel plates are utilized in architectural projects for their aesthetic appeal and functional properties. They can be used for wall cladding, elevator interiors, escalator steps, and exterior facades, adding a touch of sophistication and safety to the design.

4. Walkways and Staircases: Checkered stainless steel plates are commonly employed for walkways, stairs, and ramps in commercial and public buildings. The slip-resistant surface ensures safe passage for pedestrians, especially in areas with high foot traffic.

5. Kitchen and Food Processing: Checkered stainless steel plates are used in commercial kitchens, food processing facilities, and restaurants. They are suitable for applications such as food preparation areas, serving counters, and kitchen flooring, where slip resistance and hygiene are critical.

6. Decorative Applications: Checkered stainless steel plates can be used for decorative purposes, such as wall panels, ceiling tiles, and furniture accents. The unique diamond pattern adds visual interest and texture, enhancing the overall aesthetics of the space.

In conclusion, checkered stainless steel plates offer enhanced slip resistance, durability, corrosion resistance, and aesthetic appeal. Their use in industrial, architectural, transportation, and decorative applications highlights their versatility and reliability. Whether used for industrial flooring, transportation