Shanghai Bozhong Metal Group Co., Ltd. |

|

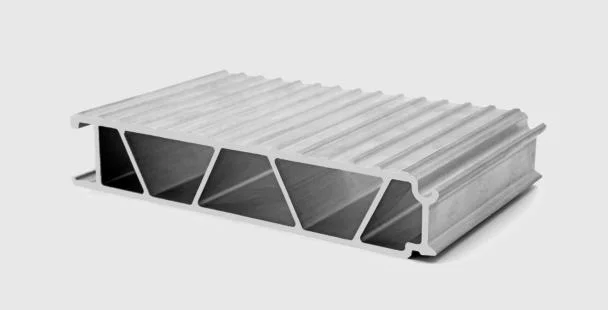

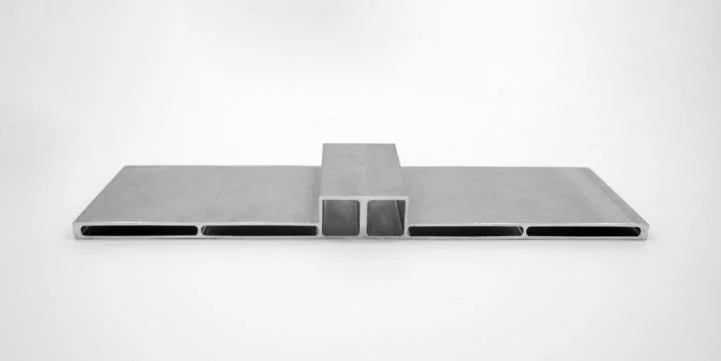

| NO. | DESCRIBTION | CONTENT |

| 1 | Material | AA1070,3003,6061,6063 are typital |

| 2 | Temper | T3-T8,etc |

| 3 | Length | Up to 6000mm |

| 4 | Width/Diameter | Up to 200mm |

| 5 | Height/Diameter | Up to 200mm |

| 6 | Wall Thickness | At Least 0.5mm |

| 7 | Dimension Tolerance | Follow up GB or ISO or custom |

| 8 | Shape | As per specification |

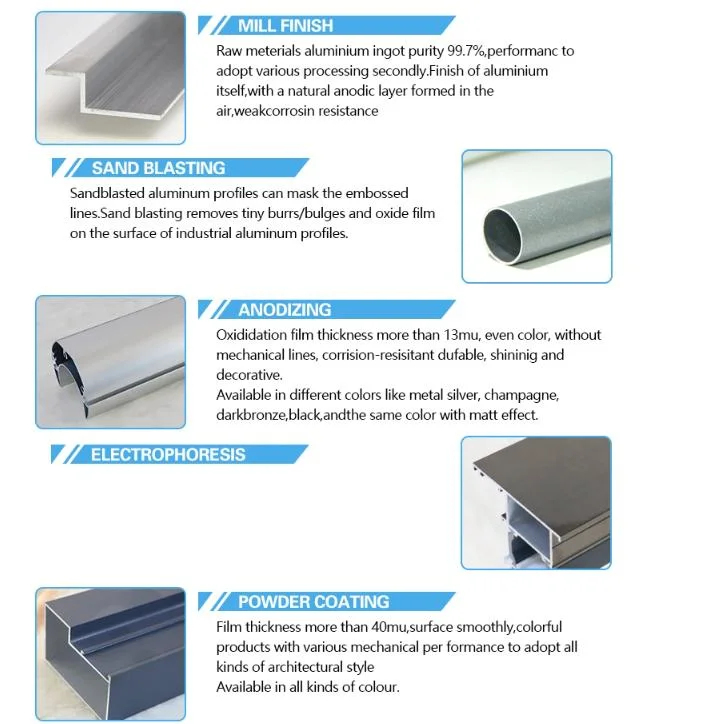

| 9 | Surface Finish | Mill Finish, painting, powder coating, oxidation,etc |

| 10 | Packing Way | To be packed in wood crate or case |

| 11 | Application | Industrial, building fields |

What is Aluminium Extrusion?

Extrusion is the introduction of a heated aluminium ingot into a

container and forcing it at high pressure through the profiled

opening of a die which corresponds to the cross-section of the

extrusion.

Why Aluminium Extrusion?

More and more people are realizing the benefits that aluminium

extrusion can offer: AThe unique properties of aluminium in

combination with the virtually unlimited opportunities the

aluminium extrusion process gives to adapt product shape to

innovate, reduce cost and maximize efficiency. From automotive to

architecture, furniture to facades, lifts to lighting, the use of

aluminium extrusions is extensive and new applications are being

discovered every day.

Besides, the cost of aluminium extrusion is significantly lower

than other processes, such as casting or forming and other

extrusion processes such as plastic. Costs vary depending on the

size, type, and complexity of extrusion.

In addition, the low density of aluminium results in a lightweight

profile compared to other materials, which is easy to handle down

the supply chain, as well as being cheaper and more environmentally

friendly to transport.

How to change the design into a real product?

CAD drawings evaluation as per extrusion natures-

CAD drawings finalized-

Tooling drawings approved and 100% prepayment for tooling fee-

Tooling development-

Extrusion-

Off-tool samples for approval-

30% Prepayment for bulk production-

Bulk production-

Balance payment-

Delivery

1. Technician team: over 30 years of experience in Aluminium extrusion for industrial application.

2. Rich source of Aluminium ingot locally.

3. Export staff embodied with fluent English communication skills,

good knowledge in aluminium extrusion industries, and exports.

Stable and reliable to help to sort out all problems.

4. Wide range of Aluminium alloy materials available.

5. Undertake any quality problems unconditionally.

Q1: Any MOQ required?

A: We accept any quantity you may need. But there will be set-up

charge for small order.

Q2: What is the lead time for tooling and off-tool samples?

A: For small tooling (External size less than 229mm), it takes

about 10-15 days for tooling and about 5 days for off-tool samples

preparing.

Q3: How about the payment terms?

A: For tooling, 100% prepayment by TT bank; for bulk production,

30% prepayment by TT bank, and balance against delivery.

Q4: Will you send videos or pictures in the processing?

A: Yes, we will keep you updated about the status here by sending

videos or pictures.

You can start with a small trial. Just send me your drawings!

Look forward to hearing from you.