GUANGDONG HWASHI TECHNOLOGY INC. |

|

Verified Suppliers

|

|

Flexible 6 Axis Welding Robot with Multi-Torch Compatibility and Versatile Power Options for Diverse Welding Processes

Six-axis robots provide maximum working range and can be installed from multiple angles to improve the flexibility of the system. The mechanical arm can install various types of welding torches. Various welding power sources can be matched to meet different welding requirements and realize various welding processes.

.

Product Features

1. The further development of programmable production automation is

flexible start-up. Industrial robots can be reprogrammed according

to the change of their working environment. Therefore, it can play

a good role in the flexible manufacturing process of small batch

and multi variety, and it is an important part of flexible

manufacturing system;

2. Anthropomorphic industrial robots have human like walking, waist

turning, big arms, small arms, wrists and claws in mechanical

structure, and computers in control. In addition, intelligent

industrial robots also have many "biosensors" similar to human

beings, such as skin type contact sensors, force sensors, load

sensors, visual sensors, acoustic sensors, language functions, etc

. The sensor improves the adaptive ability of the industrial robot

to the surrounding environment;

3. Generality in addition to specially designed industrial robots,

general industrial robots have good versatility in performing

different tasks. For example, replacing the end effector (claw,

tools, etc.) of industrial robots can perform different tasks.

Product Parameters

Model | HS-R6-08 | HS-R6-10 | HS-R6-20 | HS-R6-50 | HS-R6-165 | |

DOF | 6 | |||||

Driving Mode | AC Servo Driving | |||||

Effective Load | 8KG | 10KG | 20KG | 50KG | 165KG | |

Repeat Accuracy | ±0.05mm | |||||

Working radius | 1400mm | 1589mm | 1595mm | 1950mm | 2483mm | |

Weight | 180KG | 180KG | 290KG | 600KG | 1300KG | |

Motion Range(°) | J1 | ±170 | ±170 | ±170 | ±180 | ±180 |

J2 | ±120~-85 | ±120~-80 | ±132~-95 | ±130~-90 | ±80~-60 | |

J3 | ±85~-165 | ±85~-165 | ±73~-163 | ±75~-210 | ±80~-190 | |

J4 | ±180 | ±180 | ±180 | ±360 | ±360 | |

J5 | ±135 | ±135 | ±133 | ±115 | ±115 | |

J6 | ±360 | ±360 | ±360 | ±360 | ±360 | |

Max Speed(°/s) | J1 | 130 | 130 | 147 | 158 | 100 |

J2 | 130 | 130 | 100 | 149 | 90 | |

J3 | 130 | 130 | 135 | 130 | 104 | |

J4 | 270 | 270 | 300 | 215 | 144 | |

J5 | 170 | 170 | 198 | 251 | 160 | |

J6 | 455 | 455 | 194 | 365 | 215 | |

Power | 4KVA | 4KVA | 6KVA | 14KVA | 31KVA | |

Voltage | 380V or 220V | |||||

Frequency | 50Hz or 60Hz | |||||

Application

The application fields of industrial robots include aerospace,

automobile and parts, electronics and 3C manufacturing, food and

beverage and medicine, warehousing and logistics, rubber and

plastics - handling and processing, stone and wood products -

processing and carving, casting and pressing - forging and casting,

metal processing - welding and loading and unloading, and other

non-standard applications.

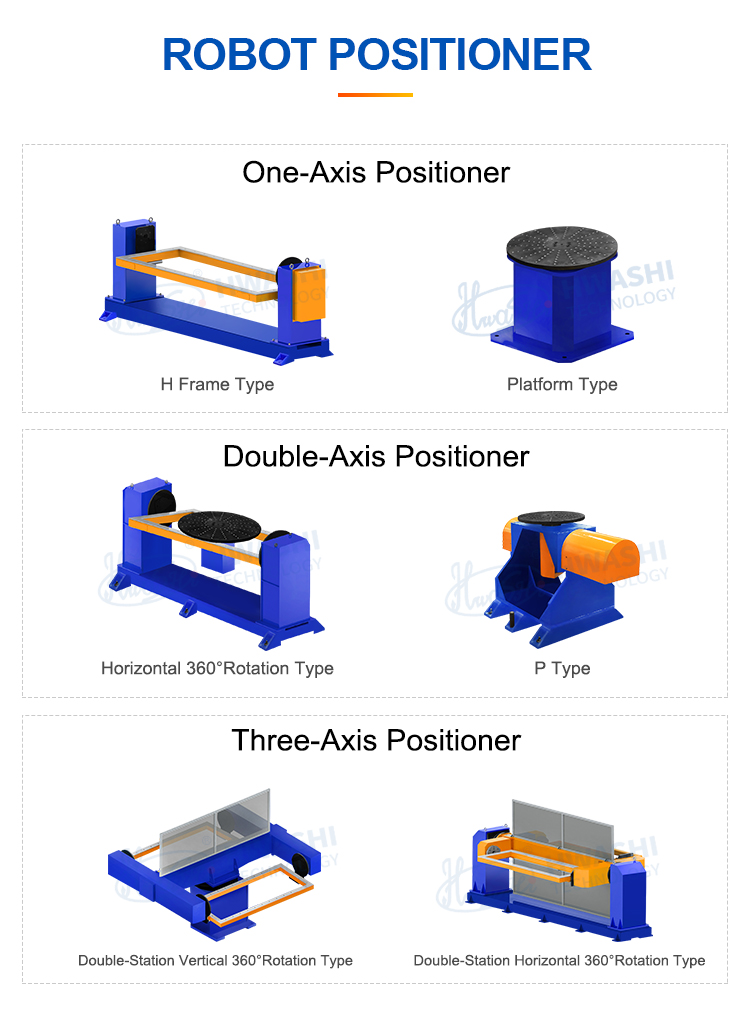

Provide different types of welding positioner

1. it can work in coordination with the robot to ensure constant

welding speed and attitude and provide higher welding quality.

2. Use imported servo motor with high precision reducer, high rotary accuracy, accurate positioning, and strong bearing capacity.

3. By turning the workpiece fixed on the worktable to the required welding angle.

Provide the 7th axis of the customized machine

1. Increase the working range of the robot to solve the disadvantages of limited working range caused by limited movement range of the robot.

2. Robot slide rail installation: the robot can walk alone or walk with matching welding power supply and robot control cabinet as a whole according to the on-site working conditions of customers.

3. Special protective mechanism to prevent welding spatter or dust in the air which will cause bad impact of precision parts.

4. In order to adapt to the different conditions of different customers, be able to do different configuration and installation for customer.