GUANGDONG HWASHI TECHNOLOGY INC. |

|

Verified Suppliers

|

|

210kg Payload 6-axis Vertically Articulated Robot Optimized for Spot Welding

SPECIFICATION

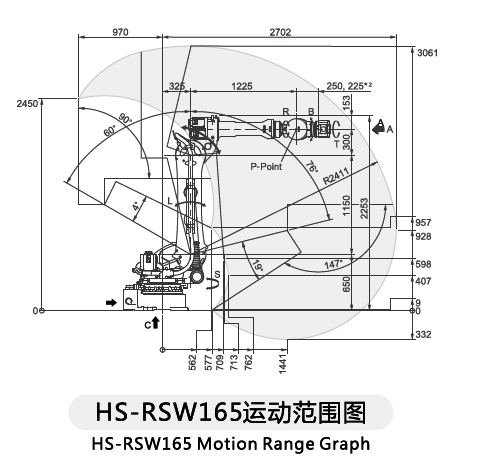

Model | HS-RSW165 | |

DOF | 6 | |

Action Mode | Vertical Multi-joint Mode | |

Effective Load (kg) | 165 | |

Motion Range (°) | J1 | -180~±180 |

J2 | -60~±76 | |

J3 | -147~±90 | |

J4 | +360~±360 | |

J5 | -125~±125 | |

J6 | -360~±360 | |

Max Speed (°/S) | J1 | 120 |

J2 | 97 | |

J3 | 115 | |

J4 | 145 | |

J5 | 145 | |

J6 | 220 | |

Moving Radius (mm) | 893 | |

Max Arm of Force | 2702 | |

DESCRIPTION

1. New vibration control system for the faster operation.

With the increased axis operation speed and speed reducer rigidity, new vibration control system was developed. By reducing the cycle time, this system realizes increase in productivity.

2. Larger range of motion even equipped with spot gun external cables

Range of motion at R-axis (wrist roll), B-axis (wrist pick/yaw) and T-axis (wrist twist) when they are equipped with external cables for spot gun are expanded. This contributes to increase the number of welding points per manipulator and the productivity is improved.

3. High-density layout is realized by the down-sized and streamlined manipulator

Compared to the conventional model, the width and the installation

area have been greatly reduced. With the reduction, higher-density

layout is possible and the productivity can be increased.

High-density layout is realized by the down-sized and streamlined

manipulator

Width : 625 mm (24.8% reduction) Installation : 34.7% reduction

4. Increased payload and decreased cables

Payload of 165 kg/210 kg while equipped with the spot welding gun

external cables is attained.

Large-sized spot welding guns are flexibly mounted.

The number of the power cable is reduced from two to one.

Cabling operation is saved and this will improve the

maintainability.

COMPETITIVE ADVANTAGE

1. HWASHI is the leading brand in resistance welding industry in China for 20 years; Factory direct sale, competitive price.

2. Customized Service: We can help to design and develop the welding machine according to your requirement. We are flexible and capable Supplier.

3. Genuine Product with Excellent Quality: 12 months warranty. Our machines are strictly complied with ISO9001:2000 and China Compulsory Certification. Most of our machines enjoy 8-10 years service life. 100% guarantee test before delivery.

4. After Sales Service and Technical Assistance: 24 hours technical support by email. Our professional team is always here willing to be your technical consultant.

5. Quick Delivery: Our company provides just-in-time delivery.

6. Prompt Response to Customers: Your satisfaction is the goal we pursue.