LIYANG APEX BIOMASS EQUIPMENT CO.,LTD |

|

Verified Suppliers

|

|

Alfalfa Rice Husk Grass Biomass Pellet Press Mill Machine 678

Main Features:

1. Siemens motor, Imported FAG/SKF/NSK bearing.

2. Equipped with auto cooling and oil adding system.

3. Lubrication system consists of automatic lubrication and manual lubrication.

4. Gear reducer with aluminum alloy housing, with compact structure, attractive appearance and high driving efficiency.

5. Ring die material: customzied alloy steel or all stainless steel, wear resistance and long life.

6. Processing of gear box: Imported CNC procesing

7. It's equipped with safe protection mechanism, when operating

overload, it could be quickly unload and protect the pellet mill

effectively.

8. Cutting mechanism equiped on the gate to control the length of pellet.

9. Pelleting for mixing raw materials, we can provide customized equipment.

10. (Optional) Intelligent automatic control system, high efficiency, cost savings, and data can be monitored.

Main technical parameters :

| Model | MZLH420 | MZLH508 | MZLH678 |

| Capacity(t/h) | 1-1.5 | 2.5-3 | 2-3 |

| Main power (kw) | 75/90 8/6P | 110/132 8/6P | 185/200 8/P |

| Feeding Power (kw) | 2.2 | 2.2 | 3 |

| Pellet Diameter (mm) | 6-12 | 6-12 | 6-12 |

Model | MZLH420 | MZLH508 | MZLH678 |

Ring die inner diameter (mm) | 420 | 500 | 688 |

Ring die working width(mm) | 90 | 100 | 110 |

Ring die linear speed (m/s) | 3.16 | 3.78 | 3.54 |

Number of clamp | 3 pcs | 3 pcs | 8 pcs |

Number of roller | 2 pcs | 2 pcs | 2 pcs |

Number of cutter | 1 pcs | 1 pcs | 1 pcs |

Motor power | 90+2.2+0.75 | 90+2.2+1.5 | 185+3.0+1.5 |

Motor rotation speed | 750 | 750 | 595 |

Ring die hole diameter(mm) | 6/8/10 | 6/8/10 | 6/8/10 |

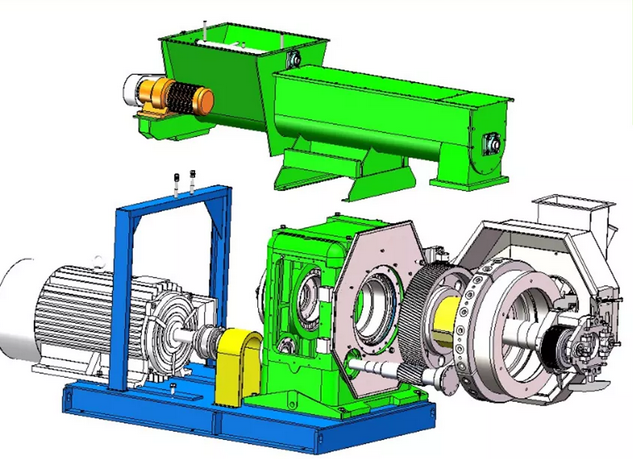

The structure of Alfalfa Rice Husk Grass Biomass Pellet Press Mill Machine 678

1. Feeder&Observation Hole:

Variable Frequency speed control, observation window to inspect the

pelletizing at any time .

2. Forced feeder:

The average quantity is fed to the main engine at a constant speed.

3.Pelleting Chamber:

Insist of two rollers, ring die, and fixing parts.

4. Safety device :

the safety pin and switch is equipped to protect main shaft and stop the electric when iron go into the chamber .

5. Ring die lifting device :

Roller shell and Ring die replaced easliy with lifting device

6. Ring die :

Customized raw material and imported processing equipment and profession heating treatment compared to others .

How to work of Alfalfa Rice Husk Grass Biomass Pellet Press Mill Machine 678

The material in the granulation bin is fed into the chute by the feeding auger, the material enters the pressing chamber through the forced feeder, and is fed into the two pressing areas in the ring die by the feeding scraper. Due to the high-speed rotation of the ring die The material is brought between the ring die and the pressure roller. Under the strong extrusion action of the ring die and the pressure roller, the material is gradually compacted and formed in the die hole. Because the extrusion of the material between the die rollers is continuous , so the formed material is continuously discharged from the die hole in a columnar shape, and then cut into particles of the required length by the cutter, and then enters the next process.

The compression ratio of Alfalfa Rice Husk Grass Biomass Pellet Press Mill Machine 678

(Compression Ratio= L/D L: Effective Die Hole Pelleting Length; D:

Effective Die Hole Dia)

Generally speaking, the higher the compression ratio, the denser

the finished pellets. But it does not mean that the higher the

compression ratio, the better the pellet quality. Compression ratio

should be calculated based on your raw material for making pellets.

Commonly compression ratio is inversely proportion to the hardness

of raw material, the harder the raw material, the smaller the

compression ratio.

Why us :

A.Good reputation

Because of the good quality and credit,our company are with good reputation both at home and abroad.

B. Factory direct supply

This ensure the competitive price available and brand care.

C. Advanced technology adopted

American CPM advanced technology with rich experience on site for installation and debugging,which has the good ability to provide with aftersale service.

D. Best and reasonable structure design of the pellet mill

This make sure the durability of the machinery running.

Gear drive of the bioass pellet mill which make the pellet machine stronger for making the wood pellets.Compared with belt drive,with lower consumption for the same capacity.