LIYANG APEX BIOMASS EQUIPMENT CO.,LTD |

|

Verified Suppliers

|

|

Anti Friction Pellet Die And Rollers Customization Alloy Steel

Opened corrugation ,closed corrugation ,fish corrufation ec as demands customized .

Top raw material from factory directly .

Alloy steel:

Top1: Germany standard: 20CrMn5

Top2: Chinese standard: 20CrMnTi

Top3: Chinese standard: 40Cr(most used)

Others:

Stainless steel: X46Cr13, Spring steel.

Accept custom-made!!!

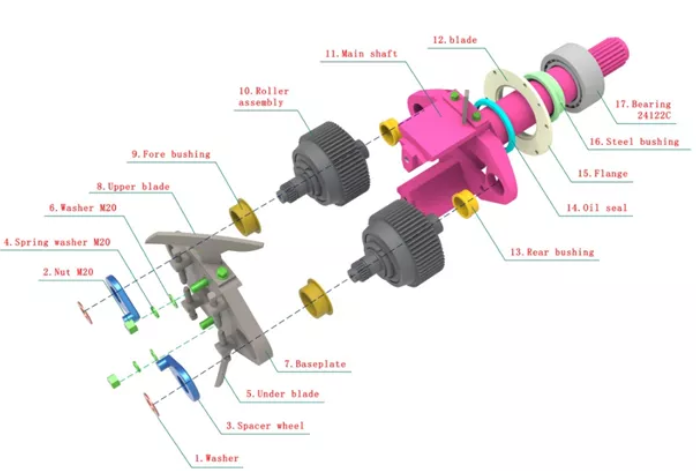

Roller shell, commonly known as pressure roller, is one of the main work parts in pellet machine and is applied for processing various kinds of biomass fuel pellet, animal feed pellet and other pellets. It is made of wear resistant alloy steel with carburization heat treatment, featuring even hardness and long service life.

Quick advantage :

1. Type of roller shell: straight tooth, helical tooth, circular

arc tooth, hole type tooth, cross-type tooth, Tungsten Carbide

roller shell, etc.

2. Material: alloy steel

3. Heat treatment: the carburized surface hardness reaches

58-60HRC, the carburized layer depth is 1.6mm, the medium frequency

surface hardness reaches 52-58HRC, and the hard layer depth of

50HRC is 5mm

4. It can provide 90% roller shell of pellet mill

5. Roller shells can be customized

Main technical paremeter of pressure roller shell :

1.Size indication: outer diameter / inner diameter X width

2. Surface processing type: through groove, closed groove, punching

3. Material: according to customer requirements

4. Hardness: HRC 58-62 according to diferent raw material

| Product Name | Pellet Roller Customization |

| Raw Material | 60Si2Mn,20CrMnTi,40Cr,X46Cr13,50#Alloy steel,42CrMo,Stainless Steel,etc( As customer demanded, |

| Certification | ISO9001, SGS, ISO14001 |

Product Type

| Roller for XGJ560,850 etc . 1.SZLH250,300,320,350,400,420,508,........ C600,TAIWANYIDA,TAIWANWANDEFU,400D,ZHENGCHENG,HDJ008...... Other Particular Dimension(L*W*H): Can be customrized. |

| Used | pellet press |

Note :

1. Correctly select the appropriate die hole compression ratio;

2. Correctly adjust the working gap between the ring die and the pressure roller to be between 0.1 and 0.3mm (the pressure roller is driven by the ring die after the new granulator is turned on in a “like rotating but not rotating” state);

3. The new ring die should be used with a new pressure roller, and the pressure roller and the ring die must be loose before and then tightened. When sharp corners appear on both sides of the pressure roller, the flange of the pressure roller should be smoothed with a hand grinder in time to facilitate a good fit between the pressure roller and the ring die;

4. The raw material must undergo preliminary cleaning and magnetic separation before the pelletizer to reduce iron pressing into the die hole. And to check the die hole regularly to see if there is any blockage. Punch out or drill out the blocked mold hole in time;