Shenzhen MingYan Technology Co., Ltd |

|

High precision 3040 Stencil Printer + CHMT48VB with vibration Feeder + T961 Reflow Oven

Small SMT Production Line

(CHARMHIGH) YOUTUBE CHANNEL:

www.youtube.com/channel/UCKRczL5Hywx59M_2SWGJOsA

1. Stencil Printer 3040 description:

| Work table size | 300*400mm |

| Print size | 250*400mm |

| Max net frame size | 370*470mm |

| Printer way | manual |

| Thickness of the substrates | 0-80mm |

| The workbench adjust volume | 10mm, Horizontal Angle adjustment |

| Printing platform height | 220mm |

| repeated accuracy | +-0.01mm |

| locate mode | Benchmark or hole shape |

| Dimension | 540*370*350 mm |

| Packing size | 630*450*480mm |

| Weight | NW.25Kg GW.35Kg |

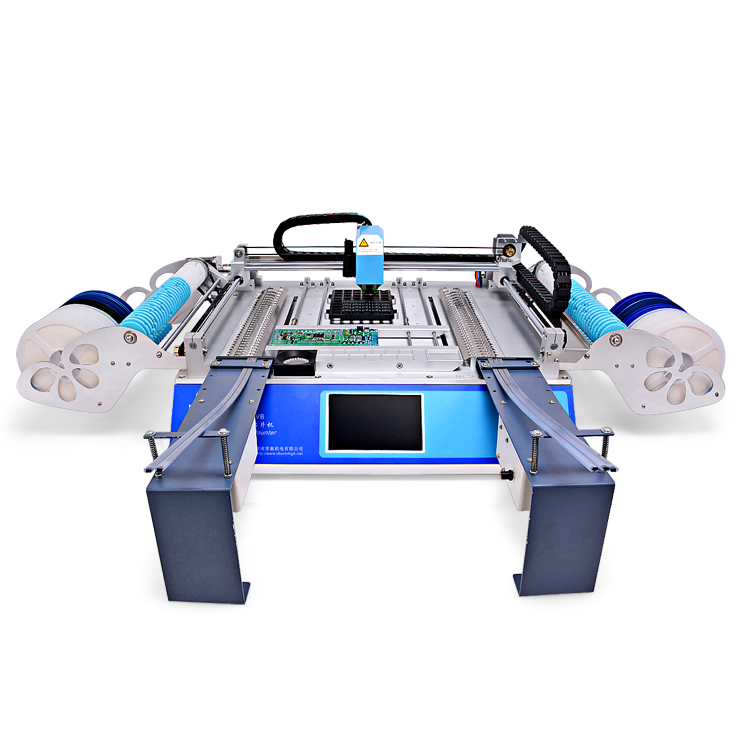

2. CHMT48VB All-in-one Machine:

| Model | CHM-T48VB |

| PCB area | 10mm*10mm - 355mm*355mm |

| X Y axis Travel | 420*460mm |

| Z axis moving range | 15mm |

| Placement heads | 2pcs |

| Feeders | Left 29pcs + right 29pcs 8mm=44pcs, 12mm=8pcs, 16mm=4pcs, 24mm=2pcs, Front IC stack=14pcs, user-defined IC tray |

| Vision system | Dual cameras (up & down cameras) |

| Drive | Closed-loop control stepper servo drive system, make sure never lose step |

| Z axis self-return detection | Yes, prevent nozzles breaking |

| Pull pin self-return | Yes |

| Leakage of material detection method | Vacuum detection, vision detection |

| Touch screen | 7”industry touch screen (USB mouse supprted) |

| Main board | Independent research industry main board |

| System | Embedded Linux system |

| Mounting speed | 5000cph (vision off); 3000cph (vision on) |

| Mounting precision | ±0.025mm |

| Components | 0402-5050,SOP,QFN (tape width: 8MM,12MM,16MM,24MM) |

| Machine dimension | L 960mm* W 705mm* H 335mm |

| Vacuum pump | -92KPA (2pcs,build-in, mute type) |

| External air source | No need (machine build-in mute vacuum pump 2pcs) |

| Compatible software | Altium designer,Protell99SE,PADS,Kicad,Eagle,Cadint,Cadence Orcad,Cadence Allegro,PROTEUS..etc |

| Voltage | 220V (110V), 50Hz |

| Net weight | 68kg |

| Gross weight | 82kg / 118*80*52cm / 0.49m³ |

3. T-961 Reflow oven parameter:

| Model | T-961 |

| The heating zone quantity | upper3/down3 |

| The length of the heating zone | 730mm |

| The heating type | intelligent level sirocco and rapid infrared heating |

| The cooling zone quantity | 1 |

| Maximum width of PCB board | 230mm |

| The operation direction | left→right |

| Delivery options | Net transmission&chain transmission |

| The speed of conveyer belt | 0-290mm/min |

| The power supply | 220V 50/60Hz |

| Peak power | 3.5KW |

| Heating up time | Around 7mins |

| Temperature control range | Room temperature-300 |

| Temperature control mode | PID closed-loop control |

| Temperature control accuracy | ±1 |

| PCB temperature distribution deviation | ±2 |

| Overall dimensions | 1000×466×445mm |

| Machine weight | 70KG |

Pictures as follows:

1. Stencil printer size 250*400mm

2. CHMT48VB 58pcs feeder pick and place machine:

3. Reflow oven T-961

Applications industry:

Household appliances industry, Auto electronics industry, Power

industry, LED industry, security,instruments and meters industry,

communications industry, intelligent control industry, Internet of

Things(IOT) industry and military industry, etc.

Q1: What is the lead time of your products? (How long do you need to prepare my goods?)

A: 2-3 days for 1-3 unit machine. 5-15 days for mass production orders (based on different quantities).

Q2: How will you deliver my goods to me?

A: We usually ship by international expresses such as DHL,UPS, FedEx, TNT to enable our customers get their goods rapidly. For bigger quantity, ship by air or by sea.

Q3: How long do I need to wait before my goods arrive?

A: 3-7 days for international express. 5-8 days for air transportation. 20-40 days for sea transportation.

Q4: What is your product quality?

A: Our raw materials are purchased from qualified suppliers, the best qaulity in China. And our engineers all have over 20 years expereinces in Machinery, ensure good quality and functions. Now CharmHigh's Quality and feedback is better than other brands in China.

Warranty:

The complete machine has a warranty period of 1 year from the time of purchase and lifelong service

support as well as a long

term factory price supply. (Artificial damage except)

We provide online Q/A and troubleshooting support and technical advice service. Provide one to one after-sale service.

If your machine or machine part is defect on transportation, please take photos and send to our email, we will make placement of damaged parts to you soon.

Each machine 100% test well before

ship out.

Tech support:

Kimi Mob: 0086 135 106 75756

Skype: kimiliu89 .

E-mail: kimi@charmhigh-tech.com

Standard package service:

The package of our P&Ps is standard export wooden package

to avoid the damage during the transportation.

Transportation service:

For package below 200 kg , you can use DHL, Fedex or other express company, For large quantities, you could use sea delivery.

Competitive Advantage:

1. Convenient software, Embedded Linux System of the machine, industry system, more professional and stable,

independent operation, no need external computer, operation more

easy and convenient.

2. Industry full touch screen operation, no need external screen,

room saved, more convenient operation, USB mouse supported as well.

3. Top and bottom two cameras CCD system correct the position of each components very accurate, especially for IC.

4. It has flexible PCB clamping fixture, and it has user-defined IC tray, convenient and quick.

5. The vision also can second correction machine origin point, make

sure origin point correct.

6. With two nozzles placing heads, high precise Juki Nozzles with magnet, no need to disassemble with wrench. 2 nozzles

arbitrary rotation angle -180 degree~ +180 degree. Placing height can adjustable.

7. Pull pin automatically return to avoid nozzles broken, pull pin not be stuck, big progress.

8. Z axis detection, placement head can auto back to origin to prevent nozzles broke.

9. Closed-loop control, X,Y Axis with encoder, never lose steps.

7. PCB by calibrate two components position ---- first and last

component, amend the offset of PCB.

8. Calibration can be rapidly and accurately for PCB, do not need

to care about offset, no need to calculate the input.

9. Comes with vacuum testing, with automatic feeding; if one

component suck crooked, it will automatically throw it to the feed

zone, then pick a new one to mount again.

10. If lack material it will automatic detection, machine will

alarm and stop; after supply material, then continue working, no

need to re-start.

11. Support any number of PCB batch.

12. If no PCB file, or don’t you don't have work file, you can

create a new file to program in machine directly.

13. Support single step.

Why choose Charmhigh?

1.Professional design and room saved.

2.User friendly operation, no need professional SMT engineer,

entry-level device

3.One machine - Integrated operation, no need extra pump or PC or

any supporting facility

4.High accuracy and reliability, make up the defection of manual

work

5.Cost efficient, reduce expense to own a professional automatic

SMT production line

6.International express with door to door service,3-5 working days

delivery

7.Especial for laboratory research and development, samples, to

avoid any patents and designs revealment.

8.One machine equal to 5 soldering staff, easy manage and cost-saved. Good for small batch production.

9.Charmhigh Is factory supply, all of our machines parts are researched and manufacturing by ourselves. After-service spare parts never stop.

10. Charmhigh is a professional manufacturer of SMT Pick and Place

machine since 2009. All the software are researched by ourselves.