Shandong Xiangtong Huiyuan Metal Materials Co., Ltd. |

|

Outer Diameter: 10-219mm

Wall Thickness: 2-10mm

Main Material: 10# 20# 35# 45# 40Cr 16Mn 40Cr 12Cr1MoV 25Mn 37Mn5

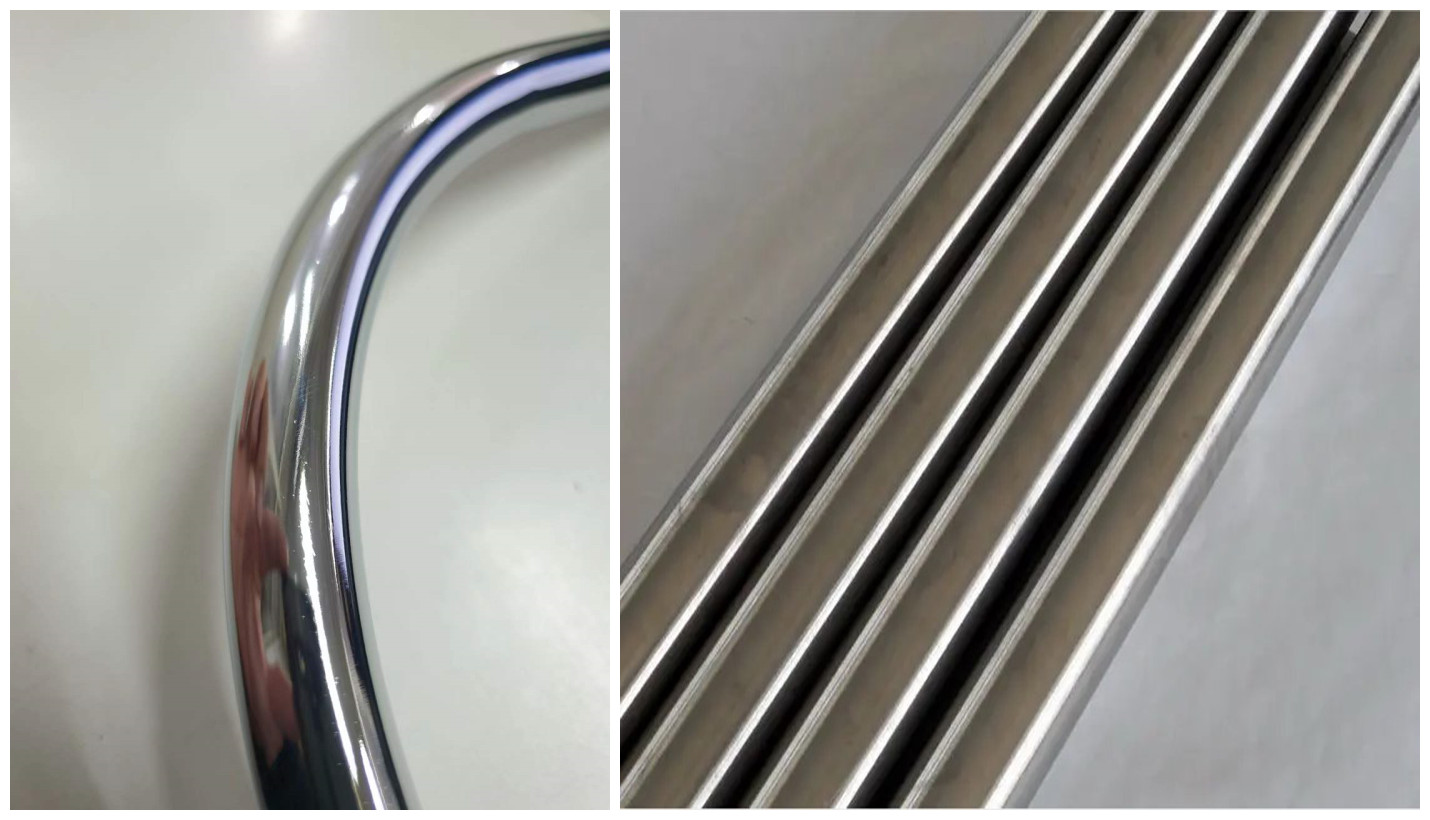

Cold Rolled Precision Steel Pipe is a kind of high-precision steel pipe material processed by cold drawing or hot rolling. Because there is no oxide layer on the inner and outer walls of the precision steel pipe, no leakage under high pressure, high precision, high finish, no deformation after cold bending, no flaring, no cracks in flattening, etc.

| Product name | Cold Rolled Precision Steel Pipe |

| Thickness | 0.5-12mm |

| Diameter | 10-200mm |

| Standard | GB, ASTM, DIN, JIS |

| Material | 10# 20# 35# 45# 40Cr 16Mn 40Cr 12Cr1MoV 25Mn 37Mn5 |

| Surface | Oiled and Bright |

| Packing | Standard Export Packing, Or According to Customer Requirements. |

| Application | Precision Machinery,Automobiles,Motorcycles,Electric Vehicles Petrochemicals |

| Port of delivery | QINGDAO, TIANJIN and SHANGHAI |

| Payment term | T/T or L/C |

| Certificate | ISO 9001 |

| Lead time | 15-50days according to order quantity |

| MOQ | 5tons each size |

| Type | seamless |

| Technique | Cold Rolled |

| Inspection | Acceptable |

| Price term | FOB,CIF,CFR |

Application

Automobiles

Motorcycles

Electric Vehicles

Petrochemicals

Electric power

Ships, Aerospace

Bearings

Pneumatic Components

Medium and Low Pressure Boiler Pipe

Steel Sleeves

Bearings, Hydraulics

Machining and other fields.

Standard requirement

1. Appearance of cold-rolled steel pipe

Cold-rolled steel pipes are not allowed to have any traces of cracks on the outer surface and its inner surface, even if it is very slight, and on its inner and outer surfaces, There can be no fold marks, rolling marks, delamination marks and scarring. If any of these problems appear on the surface, it is unqualified, and these marks need to be eliminated again, so as to achieve In a perfect state, the most important thing is that when cleaning these defects, the depth of cleaning has a certain limit, and the thickness it cleans cannot be greater than its allowable range.

For cold-rolled steel pipes, the cleaning value of the steel pipe cannot be greater than 4% of the nominal wall thickness, that is, if the wall thickness of the steel pipe is 1.4 mm, the allowable cleaning thickness is below 0.05 mm. not more than 0.05 mm.

2. Features and functions

The use and application of cold-rolled steel pipes can save a lot of steel, and can also improve the efficiency of production and processing of products.

The use of cold-rolled steel pipes also greatly saves a lot of energy. High-precision steel pipes can reduce processing time, improve material utilization, and improve product quality.

Process

Tube blank - inspection - peeling - inspection - heating -

perforation - pickling and passivation - grinding - lubrication and

air drying - cold rolling - degreasing - cutting head - inspection

- marking - Product packaging.

Delivery Conditions

BKS(+SR): After the final cold drawing process there is a stress relieve heat treatment in a controlled atmosphere.

NBK(+N): After the final cold drawing operation the tubes are normalized in a controlled atmosphere.

GBK(+A): After the final cold drawing process the tubes are annealed in a controlled atmosphere.

BK(+C): No heat treatment after the final cold drawig process.

BKW(+LC): After the final heat treatment there is a suitable drawing pass.

Working Method

Steel pipe cold working methods include cold rolling, cold drawing and spinning, which are mainly used to produce small diameter, precision, thin-walled and high-strength pipes. Cold-rolled steel pipes have smooth surface, accurate size, good performance, many cross-sectional shapes and high metal utilization rate. They are widely used in defense and military industry, machinery, mining, chemical industry, electric power, agricultural machinery and other fields. The cold-rolled steel pipe process is developed on the basis of the cold-drawn steel pipe process. It solves the problems of small deformation, many passes, high metal consumption and poor deformation conditions in cold drawing.

Main standards: DIN2391, DIN2445, EN10305, DIN1629, DIN1630, ASTM A179.