Dongguan Fulund Intelligent Technology Co., Ltd. |

|

Top Selling Tyre Rubber Frame Type Vulcanizing Press Machine

Fulund has a long history since its establishment in 1999. Due to the needs of development, the original brand (TYL) expanded the new brand Fulund in 2022 . Fulund has customers all over the world,such as international brands shoe manufacturer.

Fulund mainly produces: Hot label machine, foam cutting machine, insole hot stamping machine, shoe tongue transfer hot stamping machine, insole heat transfer machine, insole cutting and transfer integrated machine, insole printing machine, silk screen printing machine, embossing machine, soft rubber equipment , vacuum vulcanizing machine, silicone labeling machine, glue dispensing machine, etc.

Troubleshooting of Fulund vulcanizers

Since the vulcanizer is made of metal with high hardness, it is

subjected to vibration shock and other compound forces during

production and operation, resulting in the formation of gaps in the

components and causing wear. The traditional repair methods include

surfacing, thermal spraying, electric brushing, etc., but several

methods have certain drawbacks: surfacing will make the surface of

the part reach a high temperature, causing deformation or cracking

of the part, affecting dimensional accuracy and normal use, In

severe cases, it will lead to fracture; although the brush

crossover has no thermal influence, the thickness of the crossover

layer should not be too thick, the pollution is serious, and the

application is also greatly limited. Western countries use polymer

composite materials to solve the above problems. It has

comprehensive performance and can be machined at any time, which

can meet the use requirements and precision after repair, and can

also reduce the impact and vibration of the equipment during

operation and prolong its service life. Because the material is a

"variable" relationship, when the external force impacts the

material, the material will deform to absorb the external force,

and expand and contract with the expansion and contraction of the

bearing or other components, and always maintain a tight fit with

the components to reduce the probability of wear. For the wear of

large vulcanizers, "molds" or "matching parts" can also be used to

repair damaged equipment on site, to avoid the overall disassembly

of the equipment, to maximize the matching size of the parts, and

to meet the production and operation requirements of the equipment.

Introduction to the structure of the vulcanizer:

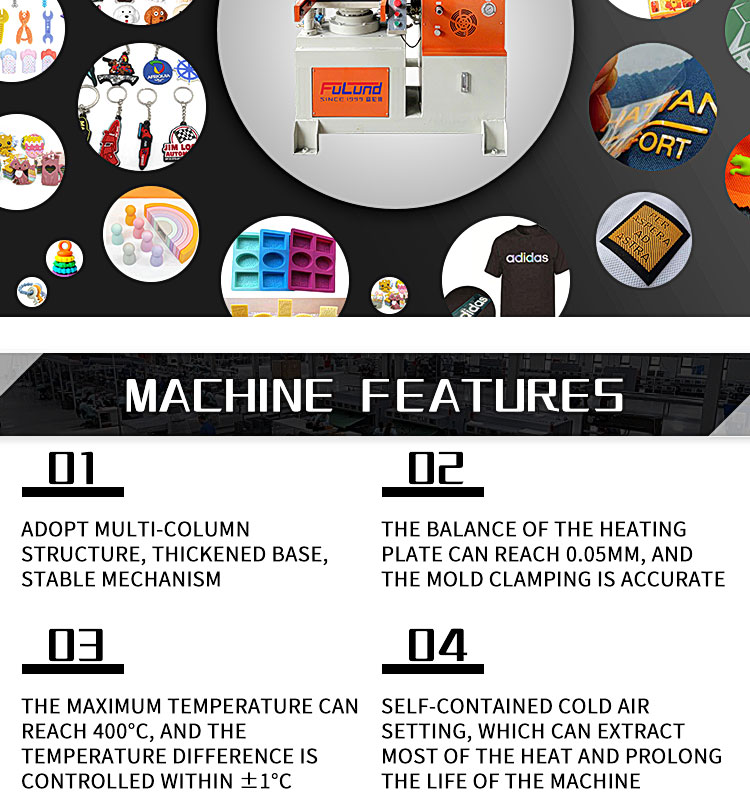

1. Structural stability: a special four-column structure is adopted, the upper seat is reinforced with medium carbon steel, and the upright column is thickened and hardened to ensure structural stability and accuracy.

2. System: The high plane pressure equalization correction is adopted, and the pressure (18mpa) strengthens the nut leveling device, which can increase the parallelism of the upper and lower heating plates to 0.05mm.

3. Temperature control system: Adjustable from room temperature to 350°C, using intelligent temperature control to control the temperature fluctuation range within ±2°C.

4. Operating system: PLC combined with touch screen, whether debugging or production, can be controlled directly and simply.

5. Operating system: The optimally designed oil circuit and high-quality oil circuit accessories ensure the smooth operation of the entire oil circuit system from the principle and accessories.

6. Energy-saving system: The heating plate adopts the deep hole processing technology, which is closely matched with the heating pipe to reduce the heat loss during the heat transfer process.

7. The intelligent system can automatically push out the mold, thereby reducing the labor time of the staff, increasing efficiency, high output and saving time.

Scope of application:

Children's toys, baby products, kitchen supplies, clothing labels, equipment seals, etc.

Technical parameters:

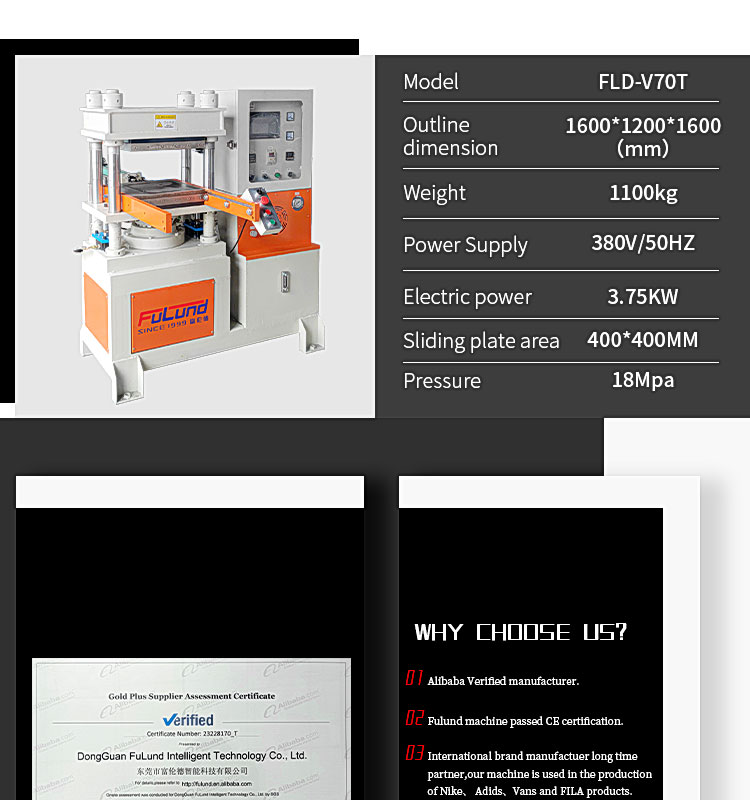

| Model No. | FLD-V70T |

| Machine size | 1600*1200*1600mm |

| Weight | 1100kg |

| Power | 13kw |

| Hot plate specifications | 400*400mm |

| Temperature range | Normal temperature -350℃ |

| Hot plate spacing | 200mm |

| Way to heat up | Imported heating tube |

| Mold opening method | Automatic mold release |

| System pressure | 18MPa |

| Main column diameter | 210mm |

| Clamping stroke | 220mm |

| Work level | Upper and lower layers |

| Motor power | 3.75kw |

| Greatest pressure | 70 tons |

| Machine structure | Four-column/single-head model |

| Power specifications | 380V/50HZ |