WUXI LINBAY MACHINERY CO.,LTD |

Heavy Duty Automatic Galvanized Steel Perforated Cable Tray And Cover Roll Forming Line

The main purpose of the cable tray cover(cable tray roll forming machine/cable tray bending machine) is to better protect the cable tray from excess hazards and, naturally, to increase the service life of the cable tray. Slotted cable bridges can be installed without a cover plate, but in the following specific cases it is necessary to install a cover plate:

1. if the cable tray is to be installed outdoors with a cover plate at the top or on each level. (perforated cable tray roll forming machine/ perforated cable tray bending machine)

2. if the installation site is susceptible to mechanical damage or dusty environments, or if special requirements apply.

3. if the cable trays are installed underneath iron plates or similar perforated devices, the top cable tray must be fitted with a cover. (cable trunking roll forming machine/cable trunking bending machine)

4. if the total width of the upper cable tray is lower than the total width of the lower cable tray, the lower cable tray must be fitted with a cover.

5. If the cable tray is installed vertically, the cover must be installed at a distance of up to two metres from the ground. (cable cover roll forming machine/cable cover bending machine)

The traditional way of fixing the cover of the cable tray(cable tray roll forming machine/cable tray bending machine) is by means of a buckle, i.e. a bent hook is welded on the cover and a buckle is welded in the corresponding position of the cable tray(perforated cable tray roll forming machine/ perforated cable tray bending machine), which will be buckled on the corresponding bent hook of the cover during installation, i.e. the fixing of the cover is completed. As the buckle is welded to the bridge, the cover and the bridge must correspond well during installation on site, and the position must not be misplaced. The welded buckles are very easy to fall off. The frequent vibrations require the fixing of the bridge cover to be quite solid and rigidly connected. Due to the large shape of the bridge and the welding of a buckle on the outside, the buckle can easily scratch other bridges during handling and long-distance transport, resulting in bruising of the bridge and loss of the buckle. Moreover, the buckles are easy to remove after installation and can be loosened by hand, which is very unsafe. (cable trunking roll forming machine/cable trunking bending machine)

The technical solution used in the new equipment is a fixing device for cable tray covers, including a tray cover, a tray with round holes on the ladder side, an L-shaped bending plate and a hook; one side of said L-shaped bending plate is welded to the outer edge of said tray cover, and the other side is provided with screw holes; one end of said hook is a curved hook, and the other end is provided with an outer folded edge, and the outer folded edge is provided with screw holes; the side of said L-shaped bending plate with screw holes The L-shaped bend is bolted to the outer folded edge of the hook, and the bend of the hook is hooked into a round hole in the ladder side of the bridge. In this solution, the L-shaped curved plate is welded on the outer plate of the bridge cover, and the L-shaped curved plate is fixedly connected to the hook that hooks the round hole on the ladder side of the bridge by means of bolts, and the hooks are tightly hooked to the bridge by tightening the bolts, so that the bridge cover is firmly fixed to the bridge. In addition, the hooks are separated from the bridges during transport, avoiding the potential for bumps and scratches between the cables. (cable cover roll forming machine/cable cover bending machine)

Flow Chart of Heavy Duty Automatic Galvanized Steel Perforated Cable Tray And Cover Roll Forming Line

5T hydraulic decoiler-Punch press-Roll forming machine-Outer table

Main Technical Parameters

| Heavy Duty Automatic Galvanized Steel Perforated Cable Tray And Cover Roll Forming Line | ||

| Component 1 | 8T hydraulic decoiler | 8 tons capacity |

| Component 2 | Leveler | 7 rollers |

| Component 3 | Punch press | 200 tons |

| Component 4 | Roll former | 7.5kw*2 |

| Component 5 | Hydraulic cut | 7.5kw |

| Component 6 | Outer table | 2 sets |

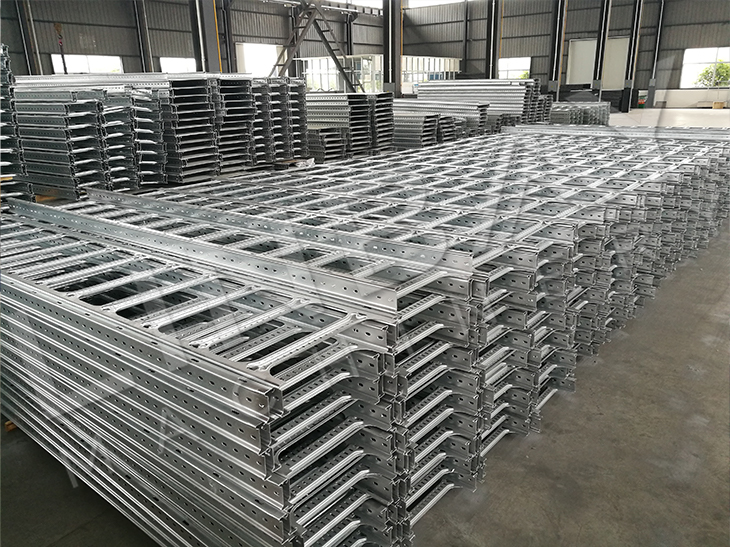

Pictures of Heavy Duty Automatic Galvanized Steel Perforated Cable Tray And Cover Roll Forming Line