BOTOU SHIBO MACHINERY MANUFACTURING CO.,LTD |

|

Hydraulic Cutting Type Roller Shutter Door Roll Forming Machine With Punching Holes

1. Brief introduction of our company

SHIBO specializes in producing and designing each kind of roll forming machine such as roll forming machines for metal roofing tiles, wall panels. While consummating the old model, with the continuous efforts of our scientific researchers, our company developed one after another of Automatic Cutting and Punching C-type Steel Roll Forming Machine, Automatic Cutting and Punching Z-type roll forming machine, the production line of Glazed Tile Roll Forming Machine, Automatic Panel Machine, Guardrail Forming Machine, Shutter Door Forming Machine, which have the advanced technical level.

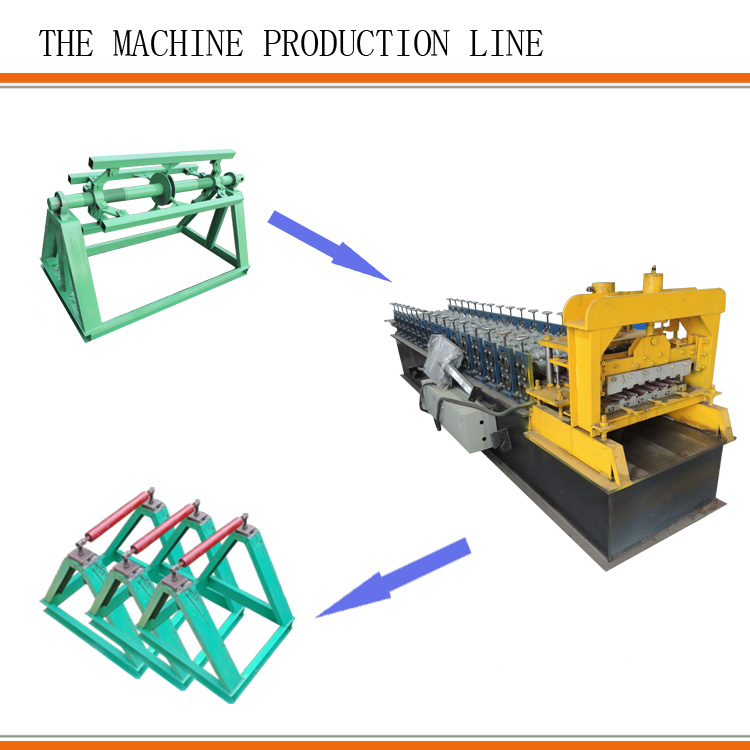

2. Components of this roller shutter door forming machine line

-- One set, manual type decoiler, five tons capacity

-- One set roll forming part, which is the main part of whole line, it forms the shape that clients need.

-- One set hydraulic cutting head, which is usually fixed on the end of the roll forming part. And we also have two types of cutting head for your choice.

-- One set discharge table, usually includes three separate small tables, which is easily moved and adjustable.

-- One set hydrualib pump station, which give the power for the cutting head and punching press device.

-- One set PLC control system, the system can keep the machine work automatically only if you have set the order as your want, which is very convenient and easy to operate.

3. Main parameters of the roll forming machine

Feeding material | PPGI / GI plate | Width of the plate | 500mm |

Thickness of the plate | 0.3 - 0.8mm | Dimensions | 7000mm*1500mm*1400mm |

Diameter of the shaft | Φ75mm | Roller station | 16rows |

Productivity | 8 - 12m/min | Total Motor power | 5.5kw+4kw |

| Weight of the machine | 2.5T | Material of roller | 45# steel, standard |

| Machine frame | Steel board welded | Sideboard thickness | 16mm |

4. Frequently asked questions

Q1, We bought your roll forming machine line, but we couldn't

install and debug it?

A1, Don't worry about that, when finished the machine, we will send

you the manual book which shows you how to use the machine; if you

still don't know, we can record a video to teach you how to operate

the machine.

Q2, About the after service, if the machine has problem out of

guarantee?

A2, All the machines are one guaranteed, life maintenance. It means

if you order our machine, you will be our customer for lifetime,

you can ask us anytime about the machine issues.

5. The roller shutter door roll forming machine details and process flow: