Zhongshan Lambert Precision Hardware Co., Ltd. |

|

OEM ODM commercial stainless steel aluminum welding sheet metal fabrication

Sheet metal bending service is often used in the enclosure or cabinet of equipment. Many times, sheet metal shell products with flat surface and beautiful appearance are the lowest cost and most efficient solutions. It can be used with welding and inlaid fasteners to quickly realize the design. Our company has advanced laser cutting machine, CNC punch and bending machine, as well as experienced team, reliable quality and stable delivery date.

![]()

Item | OEM ODM commercial stainless steel aluminum welding sheet metal fabrication |

Material | Satinless steel,iron,aluminum,alloy,brass, carbon steel, etc. |

Thickness | 0.2-50mm depends |

Tolerance | laser cutting and bending: ±0.1mm, press stamping: ±0.02mm. tube bending:±0.2 |

Size or shape | According to customer drawing or request |

Application | Used Widely |

Drawing accepted | All formats(CAD, PDF, SOLIDWORKS,ProE,UG,etc.) |

Machining | Laser cutting, punching, bending, reviting, welding, polishing, brushing, etc. |

Quality Control | ISO 9001, 100% QC Test before shipment. |

Cost control | Advanced equipment, reduce labor costs; Strict quality control, reduce defective rate, ensure delivery time. |

after-sale guarantee | If the quality problem is caused by our fault, we will take 100% responsibility. |

Surface treatment | Polishing, brushing, chrome,electroplating, powder coating,hot dip,spraying, anodizing, etc. |

Delivery Time | 7-30 days |

Company Type: | Factory & manufacturer |

Service mode | OEM or ODM, customized |

Certificate | ISO 9001 |

Feature or advantage | R&D ability, FREE design, All in one solution.cost reduction. |

Experience | OEM & ODM since 2012 |

![]()

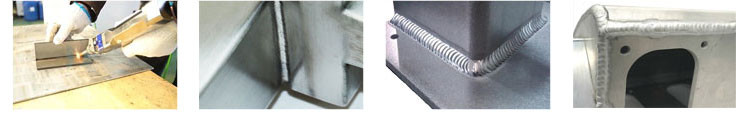

Bending parts

Sheet metal welding parts.

![]()

Step 1 : Material cutting.

| |||

| laser cutting | laser cutting aluminum | laser cutting brass | laser cutting sus plate & tube |

Thickness : 0.2mm to 50 mm

Max Range : 1500X3000mm

Tolerance : ±0.1mm

Step 2 : Bending.

| |||

| Trubend | aluminum sample | sus plate bending | sus tube bending |

long : 6 meters,

width : 2.5 meters long

Capacity : 6meters long parts.

thickness : 50mm depends.

Tolerance:±0.05 mm

Step 3 : Welding.

| |||

| laser fiber welding | argon arc welding | MIG welding | plate welding |

We also have high quality resistance welders,carbon-dioxide arc welding, etc.

Step 4 : Riveting.

| |||

| Riveting | Our sample | Our sample | Our sample |

Step 5 : Surface treatment.

| |||

| polishing | polish and brush | powder coating | polishing |

We offer polishing, brushing, chrome plating,

electroplating, powder coating,spraying,blackening,

shot blasting and so on.

![]()

|

Laser cutting material

(1) laser cutting plate

(2) 3D laser cutting pipe machine It can cut various round, square, flat and irregular tubes

in precision:

|

|

| CNC punching - Iron plate -Galvanized sheet - Aluminum coating plate - Coating plate - Plastification/ laminate - AISI 430 - AISI 304 Equipping with sheets which size up to1500*3000 mm and thickness ranging from 0.2 to 50 mm. |

|

| Robot welding We have the following equipment at our disposal for precision welding: A robotic TIG (Tungsten Inert Gas) welding centre A robotic MIG (Metal-arc Inert Gas) welding centre Both centres carry out welding works with the help of special jigs of varying complexity. In our MIG centre, for example, we are able to carry out internal weldings in various types chamber kilns. |

|

CNC turning machine High precision, complex shape,high efficiency and low cost.

Tolerance : ±0.01mm. |

|

| 5 axis machining center

High precision, complex shape, Low surface roughness, high efficiency and low cost.

Tolerance : ±0.01mm. |

|

CNC Cylindrical grinder

Very high machining accuracy.

Tolerance : ±0.002mm |

|

CNC flat grinder

Very high machining accuracy.

Tolerance : ±0.002mm |

![]()

Zhong Shan lambert precision hardware CO., LTD specializes in sheet metal processing and CNC processing.

We have advanced equipments and experienced team. We always adhere to the improvement of production technology, committed to providing high quality products and efficient service.

Our services include: customized finished products, 3D printing, various metal products, spare parts,various sheet and tube profile processing, various products and spare parts's surface treatment.

For example: laser cutting parts, stamping parts, control boxes, instrument boxes, insulation boxes. OEM metal boxes, steel brackets, steel hotel tables, seats.

Welcome to visit us for cooperation.

|  |  |

| Production meeting | Stamping workshop | Final inspection and packaging workshop |

![]()

![]()

|  |  |

| Raw maerial inspection | Precision inspection | Balance scale measurement |

|  |  |

| Internal inspection of workpiece | Salt spray test | The two sides confirmed |

![]()

Method 1: shrink film, then bulk loading.

Method 2: shrink film + box + pallet / wooden case.

Method 3: As per customer's requirements or negotiated.

![]()

» Sample & Mold

Q : Can i have a trial order or samples only for several pieces?

A : As the product is customized and need to be produced, we will charge sample cost, but if the sample is unqualified, the sample will be free or after you placed mass orders, we will refund the sample cost.

Q : Can you open mold for us to manufacture new product?

A : Yes! if the quantity is big, our company can afford part of the mold cost.

» Delivery time & after-sales service

Q : Can you provide after-sales services?

A : Generally it is 20 -30 days after the drawing confirmed. Generally

it is 20 -30 days after the drawing confirmed .

Q : Can you open mold for us to manufacture new product?

A : Yes, every defected products will be replaced and the cost be

responsble by us or we will send new ones to customer immidiately

if it is urgent. However, it would take some time for the first

production and almost 0 bad feedback from our customers after then

.

» Payment Terms

Q : What is your terms of payment?

A : T/T(For big order, 30-90 days can be acceptable), paypal, VISA,

E-checking, MasterCard.

» About quotation

Q : How can i get the quotation?

A : Please send us information for quote; drawing, material,

weight, quantity and request, we can accept PDF, ISGS, DWG, STEP

file formant.

If you don’t have drawing, please send the sample to us, we can quote base on your sample too.