Jiangyin Dingbo Technology Co., Ltd |

|

High Grade Roof Panel Roll Forming Machine For Making Ridge Capping

Final Products ( Roof tiles ) Features

1. A stylish and attractive design, giving the apperance of a

traditional roof tile.

2. Resistant to frost, heat, hail and gales ; 100% waterproof,

thanks to the lateral run-off channel on each sheet for

several models.

3. The raw material can be in different color, elegant and

noble looking. It is widely used as the garden like factory, hotel,

exhibition, villa, civil construction etc.

Machine Features

1. Precise forming.

2. High-solid forming stand guarantees the good and uniform quality

of final products

3. The operation automatically minimizes the tolerance of cutting

length.

Main Parameters

Material Spec | Colored and galvanized steel sheet (Q235) |

| Coil thickness | 0.30~0.80mm |

| Coil width | 613 mm |

| Working speed | 10~12m / (cutting time is not included) |

| Cutting tolerance | ≤±2.5mm ( length ≤5000mm ) |

| ≤±3.0mm (5000mm <length ≤10000mm) | |

| Power requirement | Main motor power: 3Kw |

| Hydraulic station power: 3Kw | |

| 3 tons manual un-coiler | Max. capacity: 3000kgs; Inner Dia.: 508mm |

| Main roller quantity | Around 11 stands |

| Type of cutting | Roll-formed and length-set cutting |

| Voltage | 380V 3phase 50HZ or as customers' requirements |

| Main body dimension | 6000*800*1500mm |

Components and Function

Coil Feeding Equipment Consists of one uncoiler with capacity of 3000kgs and its base. The mandrel can expand or shrink. With separate button to make the mandrel roll.

Guiding Equipment Adopting guiding bar and sliding block to control the width and position of the steel sheet. The coil is guided in the correct position and passed to the roll forming equipment.

Roll forming system The main frame of machine is welded separately and the outside wall is connected by screw after being roto-blasted on the surface. The rollers with quenched treatment after being machined by the exact machining tool.

Hydraulic Station Supplies the initial power to the cuter through a closed oil tank. It is off without cutting, which can save the power.

PLC Control Panel Main parts imported from Mitsubishi. The operation is easy and steady and can be choose operation by manual or automatically.

Working Flow

Decoiling the Sheet—→Sheet Guiding—→Film Covering—→Roll

Forming—→Measure Lengh —→ Cutting the Panel—→Panels to the

Supporter.

Main Accessories

1. Main machine

2. Manual/hydraulic decoiler

3. Hydraulic system

4. PLC computer controlling system

5. Forming cutter

6. Run out table (3 units)

7. User's manual in English

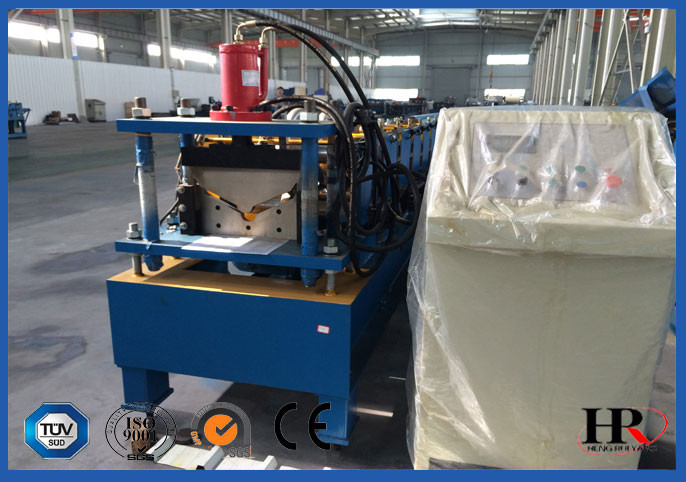

Machinery Photos

Workshop Show