Jiangyin Dingbo Technology Co., Ltd |

|

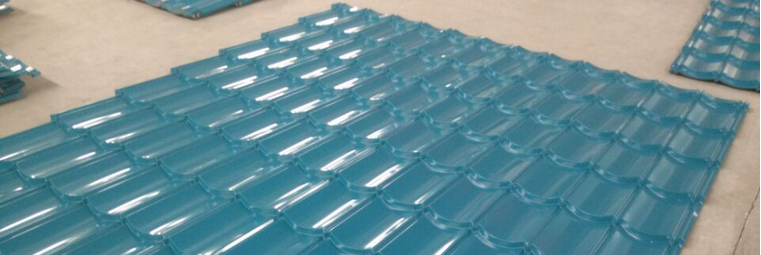

Stand Column Series Roof Roll Forming Machine , Roof Sheet Making Machine

Tile Roll Forming Machine Technical parameters

| Model | WLTM | |

| Material | Type | Pre-paited steel sheet |

| Thickness | 0.3-0.7 mm | |

| Yield stress | 230-300 Mpa | |

| Max.Forming speed | 2-3 m/min or high speed solution | |

| Roller material | 45#Steel with chrome treatment | |

| Roller driven type | Chain transmission | |

| Controller | PLC | |

| Operation | Touch screen and button | |

| Hydraulic system pressure | 12 Mpa | |

| Hydraulic station motor power | 5.5 KW | |

| Main motor power | 5.5KW | |

| Total power | 11 KW | |

| Total weight | About 8000 Kg | |

| Index error of length | 10m±2mm | |

| Voltage | 380V 3 phase 60Hz or at buyer's requirement | |

Components and Functions

| Coil Feeding Equipment | Consists of one uncoiler with capacity of 5000kgs and its base. The steel sheet is manually fed to the guiding equipment under the function of friction and traction |

| Guiding Equipment | Adopting guiding bar and sliding block to control the width and position of the steel sheet. The coil is guided in the correct position and passed to the roll forming equipment. |

| Mainframe Transmission | Transfer the main motor power to the rollers through chains and sprockets, and also transfer the coil sheet. |

| Roll forming system | The main frame of machine is welded separately and the outside wall is connected by screw after being rotoblasted on the surface.The rollers are surface-chromeplated after being machined by the exact machine tool. |

| Pressing equipment | After formed the shape of the tile panel, pressing the tile panel with pressing equipment which ensures the shape lasting and more beautiful. |

| Post Cut Equipment | The length and blocks can be set by the buyer through the control panel, when reach the set length, the machine will cut the panel automatically. The cutting is finished under the power of hydraulic station which guarantees the precision of cutting. |

| Hydraulic Station | Supplies the initial power to the cuter through a closed oil tank. It is off without cutting, which can save the power. |

| PLC Control Panel | The electric controlling system of this machine consists of five

parts: operating system, screen, PLC, transducer and strong

electricity part. The controlling system of this machine are

imported from Mitsubishi company of Japan. The system uses

modularized structure and has convenient, reasonable, canonical

wiring arrangement, and its maintenance is quite easy. The

independent operating console facilitates the mutual dialogue

between the operator and the machine. The operation is easy and

steady and can be choosed operation by manual or automatically. |

Designated use

Machinery Shows

Factory Shows

Loading Hints