Shanghai Strong Metal Production Co., Ltd. |

|

Verified Suppliers

|

|

1. What is New energy vehicle busbars

New energy vehicle busbars are a type of busbar specifically designed for use in electric and hybrid vehicles. These busbars are a critical component in the power distribution and energy management systems of the vehicle.

2.Features of New energy vehicle busbars

(1).High current carrying capacity: New energy vehicle busbars are designed to carry high currents, which is necessary to power the electric motor and other components of the vehicle.

(2).Low resistance: Low resistance is critical for efficient power transfer and to minimize power loss in the system.

(3).Lightweight: New energy vehicle busbars are often made of lightweight materials, such as aluminum alloys, to minimize the weight of the vehicle and improve its overall energy efficiency.

(4).High temperature resistance: New energy vehicle busbars must be able to withstand high temperatures, as they are often located close to the battery pack and other high-temperature components.

(5).Corrosion resistance: Corrosion resistance is important to ensure the long-term reliability and performance of the busbar, especially in harsh environments.

(6).Compact size: New energy vehicle busbars must be designed to fit within the limited space available in the vehicle's battery pack and power distribution system.

Overall, new energy vehicle busbars play a critical role in the efficient and reliable operation of electric and hybrid vehicles, and their design and specifications are carefully optimized to meet the unique requirements of these applications.

3. Specifications of new energy vehicle busbars

(1). Current carrying capacity: The current carrying capacity of the busbar is typically specified in amperes (A) and is based on the maximum current that the busbar is designed to carry.

(2). Voltage rating: The voltage rating of the busbar is typically specified in volts (V) and is based on the maximum voltage that the busbar is designed to handle.

(3). Resistance: The resistance of the busbar is typically specified in ohms and is based on the maximum acceptable voltage drop across the busbar.

(4). Dimensions: The physical dimensions of the busbar may be specified, including length, width, and thickness, as well as the spacing between the busbars.

(5). Material: The material used to construct the busbar may be specified, including any coatings or treatments applied to the surface.

(6). Temperature rating: The temperature rating of the busbar is typically specified in degrees Celsius (°C) and is based on the maximum temperature that the busbar is designed to operate at.

(7). Corrosion resistance: The level of corrosion resistance may be specified, including any special coatings or treatments applied to the surface to protect the busbar from corrosion.

Overall, the specifications of new energy vehicle busbars are carefully optimized to meet the specific requirements of the vehicle's power distribution system, including the need for high current carrying capacity, low resistance, lightweight construction, high temperature resistance, and compact size. The use of advanced materials and manufacturing techniques is often required to meet these specifications and ensure the long-term reliability and performance of the busbar in the harsh environment of an electric or hybrid vehicle.

4. Type of New energy vehicle busbar

(1). Battery busbars: These busbars are used to connect the battery cells or modules together to form a high voltage battery pack. They must be able to handle high current and voltage, and are often designed to be lightweight and compact.

(2). Inverter busbars: These busbars are used to connect the inverter to the battery pack and the electric motor. They must be able to handle high current and voltage, and may be designed for high temperature and vibration resistance.

(3). Charger busbars: These busbars are used to connect the charging system to the battery pack and may be designed for high current and voltage.

(4). Power distribution busbars: These busbars are used to distribute power from the battery pack to other components in the vehicle's power distribution system, such as the DC/DC converter or the auxiliary power supply. They may be designed to handle high current and voltage, and may be made of lightweight materials to minimize weight.

(5). Grounding busbars: These busbars are used to provide a low-resistance path to ground for the vehicle's electrical system. They may be designed to handle high current and must be made of materials that are resistant to corrosion.

5. Our company

Strong metal was established in June 2003 with a total registered capital of 67 million yuan and a totalconstruction area of 30,000 square meters. It has 5 factories in total which are located in Nantong,Taicang, Nanjing, Vietnam, and Shanghai.

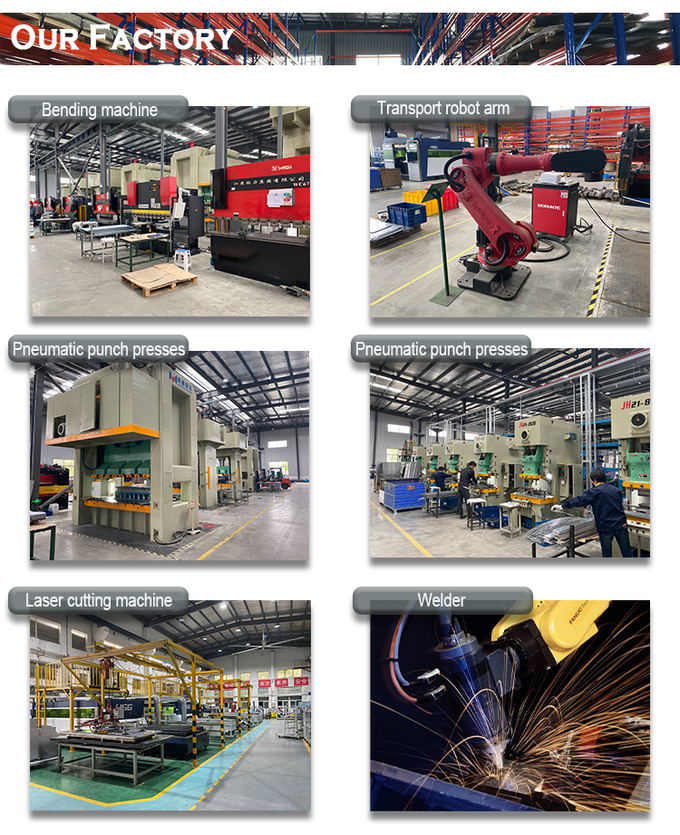

Strong has many advanced production equipment: 50+ punch press machines (highest 1000 ton),20+plastic injection machines (highest 740ton), 20+ bending machines (highest 600 ton), 20+ automatic welding arms, 50+ welding working tables, 8+ laser cutting machines, and a 400m powder coating line,etc. In terms of the QC testing tool, We have CMM, a two-dimensional measuring instrument, hardness tester, salty frog tester, etc.In 2021, the yearly turnover of Strong exceeded 200 million yuan and we keep going to search and offer better solutions to our customers and make more value to create a better world.Strong focused on metal manufacturing and has comprehensive ability in mold self-design, metal stamping, sheet metal, laser cutting, powder coating, welding, plastic injection, etc.

6. FAQ

Q: Do you provide samples? is it free or extra?

A: Yes, we could offer the sample for free but do not pay the

freight cost.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is

15-20 days if the goods are not in stock,it is according to

quantity.

Q: Are you a trading company or manufacturer?

A: We are a manufacturer.

Q: What are your terms of payment?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 30%

T/T in advance ,balance

before shipment.If you have another question, pls feel free to contact us.