Shanghai Strong Metal Production Co., Ltd. |

|

Verified Suppliers

|

|

A solar bracket is a type of mounting

system used to secure solar panels to a roof or other surface in

order to generate electricity from sunlight. Solar brackets are

typically made of metal and are designed to be strong, durable, and

weather-resistant. They come in a variety of shapes and sizes to

accommodate different types of solar panels and installation

locations.

The main types of solar brackets include roof mounts, ground

mounts, and pole mounts. Roof mounts are attached directly to the

roof and are commonly used in residential and commercial

installations. Ground mounts are installed on the ground and can be

used in residential, commercial, and utility-scale projects. Pole

mounts are attached to a pole and are commonly used for off-grid

installations.

When selecting a solar bracket, it is important to consider factors

such as the size and weight of the solar panels, the type of

roofing material, wind and snow loads, and local building codes and

regulations.

Solar brackets are typically made of metal, such as aluminum or steel. The choice of material will depend on a number of factors, including the size and weight of the solar panels, the type of mounting system being used, and the local weather conditions.

Aluminum is a popular choice for solar brackets because it is lightweight, corrosion-resistant, and easy to work with. Aluminum brackets are often used in residential and commercial installations, as they are well-suited for roof-mounted systems and can be easily installed using standard tools.

Steel is another common material used for solar brackets. Steel brackets are generally stronger and more durable than aluminum brackets, making them a good choice for ground-mounted systems and installations in areas with high wind or snow loads. However, steel brackets are heavier and more difficult to work with than aluminum brackets.

In addition to aluminum and steel, there are also hybrid solar brackets that are made from a combination of both materials. These brackets typically feature an aluminum frame with steel reinforcement in key areas to provide additional strength and durability.

Ultimately, the choice of material for a solar bracket will depend on the specific needs of the installation, and should be determined in consultation with a qualified solar panel installer or supplier.

Solar brackets may be certified by various organizations to ensure that they meet certain safety and performance standards. Some common certifications for solar brackets include:

(1)UL 2703: This is a safety standard for mounting systems, which includes testing for mechanical loading, fire resistance, and electrical bonding.

(2)ICC-ES: The International Code Council Evaluation Service (ICC-ES) provides third-party evaluation and certification of building products, including solar brackets.

(3)ASCE 7-16: The American Society of Civil Engineers (ASCE) provides guidelines for wind and seismic loads, which are important considerations for solar bracket design.

(4)TÜV Rheinland: TÜV Rheinland is a global provider of testing, inspection, and certification services, and offers certification for solar brackets to ensure that they meet certain safety and performance standards.

(5)Other certificates required by customers.

(1)Adapt to multiple scenarios: garden, balcony, railing, walls and

etc.

(2)Modular design with plug and play connection, quick and easy

installation

(3)Adjustable angle manually to adjust the PV module angle for more

energy generation.

| ||||||||||||||||||||||||||||

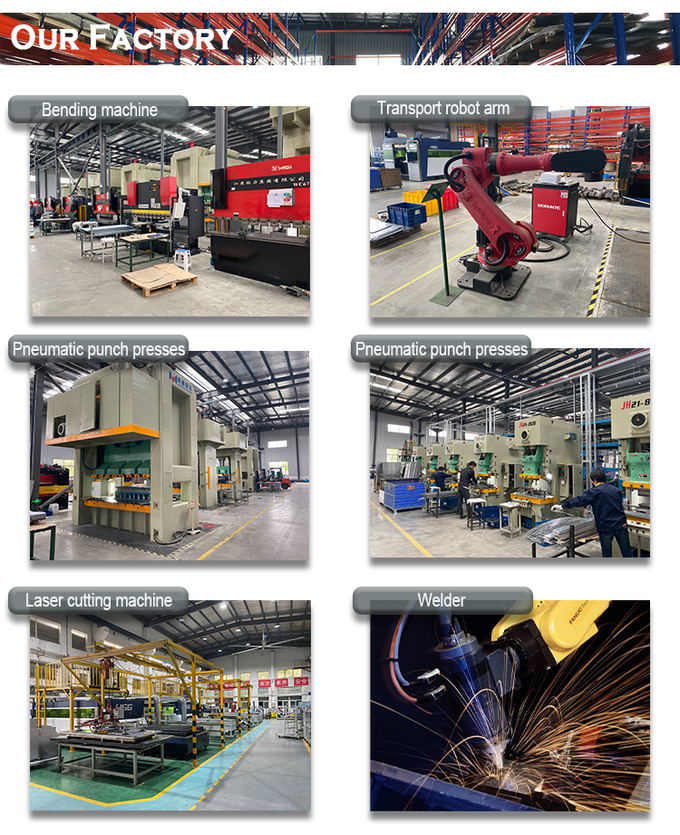

Strong has many advanced production equipments: 50+ punch press machines (highest 1000 ton),20+plastic injection machines (highest 740ton), 20+ bending machines (highest 600 ton), 20+ automatic welding arms, 50+ welding working tables, 8+ laser cutting machines, and a 400m powder coating line,etc. In terms of the QC testing tool, We have CMM, a two-dimensional measuring instrument, hardness

tester, salty frog tester, etc.

Strong metal was established in June 2003 with a total registered capital of 67 million yuan and a total construction area of 30,000 square meters. It has 5 factories in total which are located in Nantong, Taicang, Nanjing, Vietnam, and Shanghai.

The company has more than 300 employees, and more than 40 engineers, including engineering engineers,drawing engineers and so engineers, quality engineers, and process engineers. We can provide services from drawing to drawing Samples and bulk, 24 hours technical support.

Our factory's main products are OEM and ODM metal and plastic manufacturing services.

Strong focused on metal manufacturing and has comprehensive ability in mold self-design, metalstamping,sheet metal, laser cutting, powder coating, welding, plastic injection, etc.

In 2021, the yearly turnover of Strong had exceeded 200 million yuan and we keep going to search and offer better solutions to our customers and make more value to create a better world.

We could customize products according to the 2D/3D drawings from customers. We could offer laser cutting, bending, welding, powder coating, milling, molding, machining, plastic injection, and so on.

Strong focus on lean production and we aim to try out best to be more efficient, time saved, and cost saved.

Q: Are you a trading company or manufacturer?

A: We are a manufacturer.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is

15-20 days if the goods are not in stock,

it is according to quantity.

Q: Do you provide samples? is it free or extra?

A: Yes, we could offer the sample for free charge but do not pay

the cost of freight.

Q: What are your terms of payment?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 30%

T/T in advance ,balance

before shipment.

If you have another question, pls feel free to contact us.