S&G Engineering Solution Lmt. |

|

Detailed Product Description

For steel roller shutter roll forming machine, according to our company standard, we will offer you following components as the standard configuration.

Main Specifications

| Coil Material | Thickness | 0.22-0.35mm |

| Coil width | Custom-made | |

| Yield Strength | 100-260Mpa | |

| Material | Aluminum | |

| Decoiler / Uncoiler | Coil Width | Max. 350mm |

| I.D | 300mm | |

| O.D | Max. 560mm | |

| Roll Forming Machine | Forming stations | 37 Stations ( Depend on Profiles ) |

| Roller material | GCr15 steel, HRC58-62 | |

| Diameter of shaft | 40mm | |

| Shaft material | High grade 45# steel | |

| Drive type | Gear box with universal joint transmission system | |

| Forming speed | 15-30m/min | |

| Main power | 11KW | |

| Cutting | Cutting type | Pneumatic servo flying saw cutting |

| Cutting Tolerance | 10m+/-0.5mm | |

| Encoder | OMRON Brand | |

| Electrical control | PLC | Delta Brand or Custom-made |

| Inverter | Delta Brand or Custom-made | |

| Touch screen | Delta Brand or Custom-made | |

| Operation type | Touch screen & Button | |

| Runout Table | Table type | Simple nonpower type |

| Function | To support the finished panels |

A, Main technical parameters

| Working speed | 12M/min (without stop cutting time) |

| Forming roller station | according to the profile |

| Main motor power | according to the profile |

| Hydraulic power | according to the profile |

| Roller material | NO.45 steel with treatment, coated with chrome |

| Roller shaft material | NO.45 steel with treatment |

| Roller shaft diamete | according to the profile |

| Cutting type | hydraulic drive, cutting after forming |

| Shear material | Cr12 with quenching |

| PLC control system | Mitsubishi FX-IS series |

| Cut to length | 10m±2mm |

| Frequency | Dan Fuss |

| Control cabinet | xinjie OP320A |

B, Components

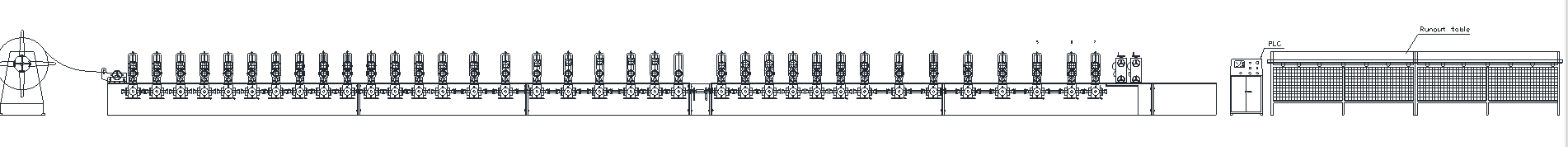

This machine is composed of 3T manual decoiler, transmission device, main roll forming machine (including guiding platform), back-seaming device, back-cutting device, PLC control system, hydraulic shear, and stacker.

C, flow chart

Decoil--guide feeding---roll forming---seaming---cut to length---run out table

D, Payment:

Pay 30% of total cost as deposit, the balance before delivery. L/C is acceptable. (Arrange the payment after the inspection of the machine is passed and before shipment.)

E, Warranty, Year warranty

During the warranty period, maintain and change the spare parts for the customers for free (except for the instrument damage caused by human factors or natural disasters.) And provide technical support for life-long.

Other descriptions,

1. Accompanied with working instructions and a CD. Please operate as required.

2. Machine only to be shipped after the inspection is passed.

3. CE certificated, guaranteed quality.

4. In a 40 feet container.

Main Components

| Main Roll Forming Machine | 1 Unit |

| PLC Computer Control Board | 1 Unit |

| Fast conveyor belt | 1 Unit |

| Decoiler / Uncoiler | 1 Unit |

| Cutting To Length | 1 Unit |

| Runout Table | 1 Unit |

Technical Process

Decoiling---foam--- Heat preservation---roll forming---automatic cutting---off---discharging

Application

For shutter door Garage door

Our Advantage

Why S&G

1), Q: Do you have after sales support?

A: Yes, we are happy to give advice and we also have skilled technicians available across the world. We need your machines running in order to keep your business running.

2), Q: How do your machines compare with other big companies in this market?

A: We are up to date with the latest technology and improve our machines accordingly

3), Q: How does your factory do regarding quality control?

A: Quality is priority. JINGJING MACHINERY People always attach

great importance to quality control from the very beginning to the

end of the production. Every product will be fully assembled and

carefully tested before it's packed for shipment.

4), Q: Do you sell only standard machines?

A: No, most of our machines are built according to customers specifications, using top brand name components

5), Q: Will you deliver the right goods as ordered? How can I trust you?

A: Yes, we will. The core of our company culture is honesty and credit. JINGJING MACHINERY is ALIBAB’s Gold supplier with BV assessment. If you check with ALIBABA, you will see that we have never got any complaint from our customers.

About S&G

To be best partner in your great business, JINGJING MACHINERY keeps exploring the best solution for all world market.

The following photos show here we do the works for you.

Contact S&G

Thanks very much for your time, welcome to contact S&G, we are with you within 24 hours.

We want to know following information.

1), What is the exact profile you want to produce?

2), What kind of material you will use, such as steel or aluminium, max coil weight, thickness?

3), What kind of decoiler and stacker you need?

Product Images:

Machine Images: