Chengdu Zhengxi Hydraulic Equipment Manufacturing Co., Ltd. |

|

Composite Molding Sheet molding compound machine , SMC Sheet Molding Compounds Product,Fiberglass Compression Molding

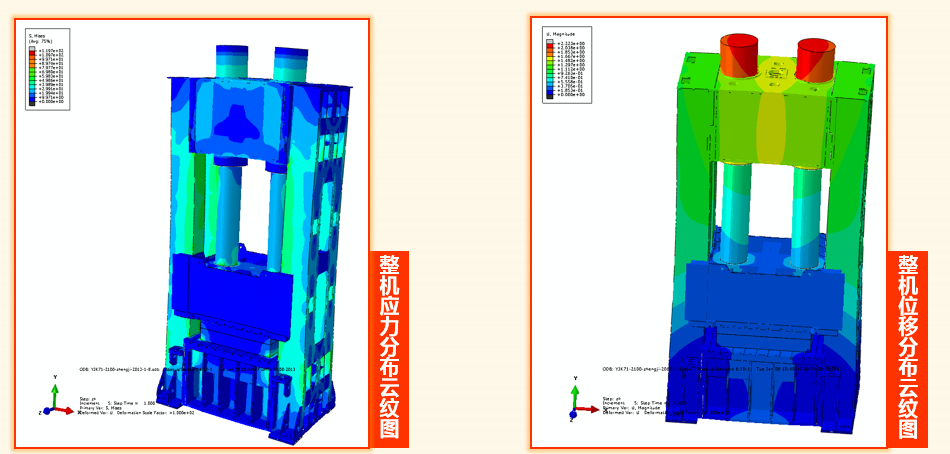

Company composite molding equipment performance characteristics

Company composite molding equipment performance characteristics

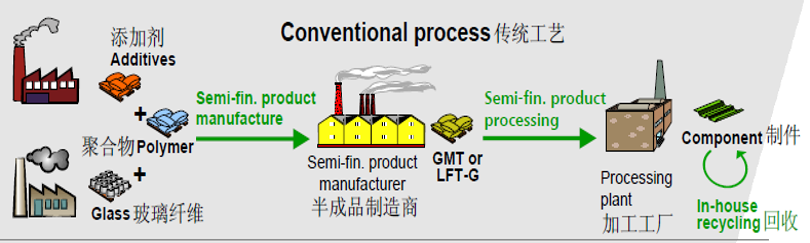

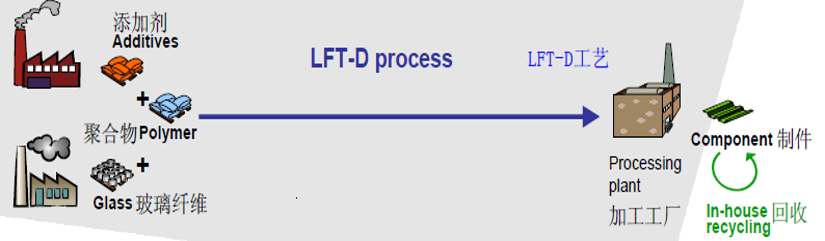

LFT-D long fiber reinforced thermoplastic directly inline molding

Main functional unit

1. Glass fiber yarn pretreatment unit: the fiber bundle is

dispersed by the yarn dividing device, and the dispersed fiber

bundle passes through the yarn guide frame and enters the yarn

immersing device. After the immersion agent is infiltrated, it

enters the drying device, and is dried and then wound on the

package for preparation. Feed into the extruder.

Compounding and extruding unit: The base resin, auxiliary agent,

fiber, etc. are mixed and plasticized in a first-order and

second-order twin-screw extruder according to a set ratio by a raw

material supply and feeding device, and the required size is

extruded. band.

2. Insulation conveying unit: The LFT material strip extruded from

the screw extruder enters the insulated double conveyor belt device

and is to be grabbed by the robot.

Robotic gripping unit: The multi-joint robot is responsible for

grabbing and placing the composite material block on the conveyor

belt in the press cavity.

3. Press forming unit: After receiving the signal, the slider goes

down and presses the block into the desired product.

4. Bus control unit: monitors all production units and their

interactions and issues action commands to ensure accurate and safe

operation. It consists of three networks: 1. PROFIBUS-DP bus; 2.

ETHERNET (industrial Ethernet); SAFETY BUS (Safety Network).

This manual sets out to describe Sheet Moulding Compound (SMC) and Bulk Moulding Compound (BMC), their composition, characteristics, processing, end-uses and recycling. Recommendations are given on how to achieve the best results and how to maximise the benefits that these unique materials offer. It is primarily intended to inform and assist design engineers and technicians, especially those working in the following industries:

Applications

Electrical & Electronics

(mechanical integrity and electrical insulation)

Low voltage and medium voltage energy systems Fuses and switchgear

Cabinets and junction boxes Motor and anchor insulations

Encapsulation of wiring and electronic circuits Electrical components with reduced surface resistivity Lamp housings

Mass Transportation

(light weight and fire resistance)

Train, tram interior and body parts Electrical components

Track switch components

Under the hood components for trucks

Automotive & Truck

(low fuel emissions through weight reduction)

Light weight body panels for vehicles

Lighting systems, headlamp reflectors and LED lighting Structural parts, front ends, interior dashboard parts body panels for trucks and agricultural vehicles

Building & Construction (durability and design freedom)

Drinking water tanks Panels

Doors

Building supply systems Drain and trench covers Access chambers