Jufu Water Technology Co., Ltd |

|

RO Water Treatment System Ultra-Pure Water EDI Water Treatment For Pharmaceutical

Technical Specifications of EDI Water Treatment Plant

EDI System | |

Model | JFEDI-1000L |

Host Size | can be customized |

Operating Pressure | 0.1-0.3MPa |

Recovery Rate | 95% |

Rack Material | SUS304/Carbon Steel (Optional) |

Pipe Material | U-PVC/ C-PVC/Stainless steel (Optional) |

EDI Brand | Ionpure/Canpure/GE (Optional) |

Raw Water Pump | CNP/NYP/GRUNDFOS (Optional) |

Tank Material | SS/FRP(Optional) |

Outlet Flow | 1000L/h |

Power Supply | 220V /380V/460V - 50Hz/60Hz,220V 50Hz can be customized |

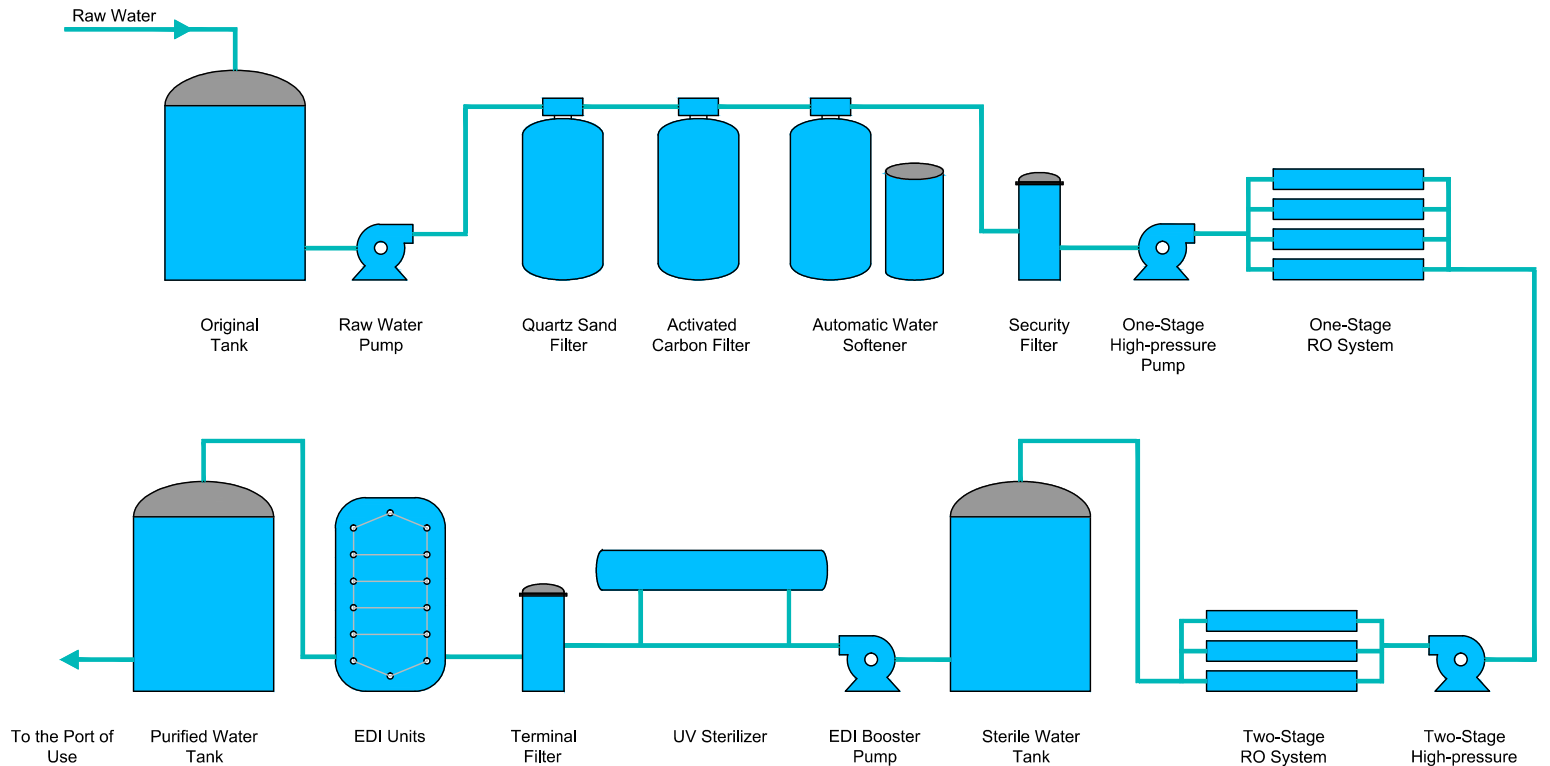

EDI Water Treatment Plant Working Principle

In the EDI membrane block, a certain number of EDI units are

separated by grids to form a concentrated water chamber and a fresh

water chamber. In turn, negative/positive electrodes are provided

at both ends of the cell. Driven by direct current, the anions and

cations in the water flow through the fresh water chamber migrate

to the concentrated water chamber through the anion and cation

exchange membrane respectively and are removed in the fresh water

chamber.

EDI Modules

The Main Reasons for EDI Water Treatment Plant

1. The EDI membrane block runs at high current for a long time, and

the accumulated heat cannot be dissipated, causing the EDI to be

close to the two poles.

The diaphragm is heated and deformed, the pressure difference of

the EDI concentrated water increases, and the water quality and

water volume decrease to varying degrees.

2. If the EDI membrane block is not cleaned and maintained for a

long time, it will cause calcium and magnesium scale on the EDI

membrane and channel, which will make the

The water pressure difference increases, resulting in a decrease in

the quality of the produced water and an increase in the voltage,

which in turn makes the current unable to be adjusted.

ultimately unusable.

3. The use of unreasonable cleaning and disinfection agents will

directly lead to damage and fragmentation of EDI resin, and water

in and out.

The pressure difference increases, resulting in a decrease in the

quality and quantity of the produced water. 4. The EDI system is

powered on under water shortage

It directly leads to the heating and burning of the diaphragm and

resin, and the cleaning is invalid and cannot be used.

5. There is no security filter before the EDI enters the water,

which directly causes foreign matter to block the EDI channel, and

the pressure difference between the inlet and outlet increases.

Caused a serious decline in the amount of water produced, cleaning

is ineffective.

6. Poor pretreatment (softener, sodium bisulfite, RO, etc.),

control system failure/failure (safety

full interlocks, low flow protection issues), improper system

design.

7. The residual chlorine in the EDI water exceeds the standard,

resulting in the oxidation of the resin of the EDI membrane block

and the oxidation of the diaphragm. Increased differential

pressure, flux decline, water quality declines.

Product Photos of EDI Water Treatment Plant

Daily Maintenance of EDI Water Treatment Plant

1. The personnel who operate the industrial EDI ultrapure water

treatment equipment must switch the equipment on and off strictly

according to the operation process, and the operator needs to

inspect the equipment at least three times a day to ensure the

normal operation of the ultrapure water equipment. .

2. The operator should do more than 2 patrol inspections every day

to ensure the normal operation of the equipment.

3. Operators and maintenance personnel should always pay attention

to keeping the equipment clean and tidy, eliminate dripping and

leakage problems in time, and make records for problems that cannot

be solved in time, and must be solved after research.

4. All joints and water pipes of industrial EDI ultra-pure water

treatment equipment should be checked regularly, such as whether

there is looseness or damage, etc., and the operation of

high-pressure pumps and water pumps should also be checked

regularly. Pay attention to Freeze-proof.

5. Regularly replace the filter screen and PP cotton of the

industrial EDI ultra-pure water treatment equipment to ensure that

the water treatment standard is within the range.

6. Regularly check the operation of the water pump and

high-pressure pump, and report any problems in time.

7. If the operator finds that the equipment is abnormal, he should

immediately find out the reason and report it in time.

8. Always check whether the connector of the electric control box

is off or disconnected, and ensure the safety of electricity use.

Our advantages, Jufu Water Purification Five Guarantees:

01 Focus on water treatment equipment for 14 years, the quality is

trustworthy;

02 The product passed the ISO9001 quality system standard

production

03 Provide free water treatment solutions;

04 Door-to-door installation service can be provided;

05 Provide lifetime after-sales service.

Pre-sale service:

1. Inquiry and purchase consultation.

2. Raw water test support.

3. Visit our factory

After-sales service:

1. Training how to install the machine, training how to use the

machine

2. Lifetime online and telephone technical support services.

3. Overseas mechanical maintenance engineer on-site service

installation or maintenance.

Here's a guide to getting the best offer

1. What is the source water to be treated? Industrial wastewater,

tap water, well water, groundwater or seawater? Is there a water

quality analysis report for conductivity?

2. How much capacity water treatment system do you need? 1000

liters per hour, 5000 liters per hour or more?

3. What is the purpose of outputting purified water? Drinking

water, food, beverage manufacturing, industrial use or medical

production use?