Jiangsu Zhuohe Mould Co., Ltd. |

|

Casting PU Post Foam Jig With 4 Inject Holes Aluminum Fixture

What is Rotational Molding?

Rotational moud or Roto Molding which is a high temperature, low volume, low pressure thermoplastic forming process .It mainly suite for producing hollow, one piece parts such as large oil or chemical tanks, kayaks, point of purchase displays, frames, cases, furniture,

carts, dispensers, park equipment. The material can be UV resistant which can ensure the outdoor use of your products .

Product Parameter

| Shaping type | Rotomolding mold |

| Mould material | Aluminum A356 6061T6 Block CNC |

| Product material | LLDPE/HDPE/LDPE/MDPE mixing powder or modified powder |

| Mould thickness | 8mm-12mm Customized |

| Product wall thickness | 4mm-8mm Customized |

| Mold making technology | Die casting and CNC |

| Design Software | CAD/UG etc. |

| Surface treatment | /Mirror/Sandblasting/Gloosy |

| Application | Kayak/canoe/cases/dispensers/park equipment/chair/frames |

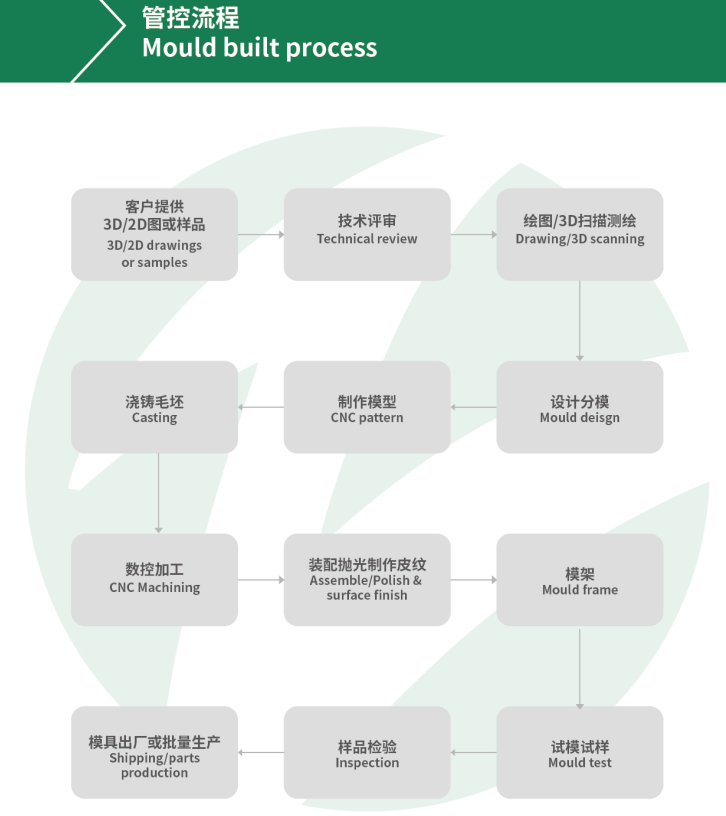

| Work Flow | Drawing confirmed→mold design→mold making→manufacture |

Genernal tools specifications:

1- Foam tooling model as casting patterns. Or, Block CNC machined

tools available.

2- Aluminum castings with cast mounting posts. (Nominal 5/16” wall

castings).

3- No or minimal porosity, guaranteed not to blow holes.

4- 2” wide x 9/16” parting lines.

5- Tongue and groove parting lines, pins design also available.

6- Tongue is on the side that will mount to arm. (So plastic powder

isn’t spilled into groove)

7- Two options for texture, 0.8mm/1.5mm shoot blasted. Mat or shiny

available.

8- Fabricated frame, minimum (1-1/2” x 1-1/2” mild steel tubing)

9- Spring loaded mounting system available.

10- Heavy duty Clamps designing available.

11- Mild steel lifting hooks available.

12- treatment available.

13- Required tools shrinkage according customer.

The following is an overview of molds available for the plastic rotational molding process.

Cast Molds are the most common type of rotational molds to produce parts varying from very small to large. Cast molds produce parts that require considerable detail or elaborate shapes and they can be modified to integrate design changes.

CNC Molds are used when extreme precision or extended production runs are required. Because of a higher cost, they are used only in special cases. When an part needs to be in production very quickly, machining the tool is sometimes the only answer.

Epoxy Molds use a liquid thermosetting polyester and epoxy material that is formed and cured at room temperature.

Fabricated Molds are the lowest cost tools and are used mainly for large parts with simple shapes. They're fabricated from steel, aluminum or stainless steel these molds and tend to be lightweight with a thin cavity wall. A fabricated rotational molding tool is the least costly approach for making with large simple molds.

The most important thing to consider with all types of molding is the quality of the mold. There is no substitute for an excellent mold. A Production rotational molder can advise you on the type of mold best for your application, and the plastic material most suitable for your product.

SUZHOU ZHUOHE MOULD TECHNOLOGY

specialized in custom aluminium rotatioanl moulds, located in Taicang city of Jiangsu, which is very close to Shanghai, one hour from Hongqiao Airport, two hours from Shanghai Pudong International Airport.

Mr.Guangming Huang, the founder of Zhuohe, with over 28 years experience in rotational moulds filed, he joined in 2008 Beijing Olympic drum project, 2010 Shanghai Expo Madrid project, China military case projects. Now he is leading a team with over 15 years experience in building aluminum rotational moulds, well mastered in developing cleaning machine part moulds, auto & fuel tank moulds , icebox series moulds, kayak moulds, planter moulds and so on.

Company plant covers an area of 6000 square meters, with 6 CNC machines and 3 rotomoulding machines and other related equipments. The annual tooling production capacity about 300 sets and molding plastic parts over 1200 tons. Exported to all countries in the world.

We offering one-stop service, from mould design to finished plastic parts ,as long as a sample or an approved drawing is sent to us, you can expect a sample within lead time.

Good quality, Good price, Good service.