Changzhou Yutai Mould Co., Ltd. |

|

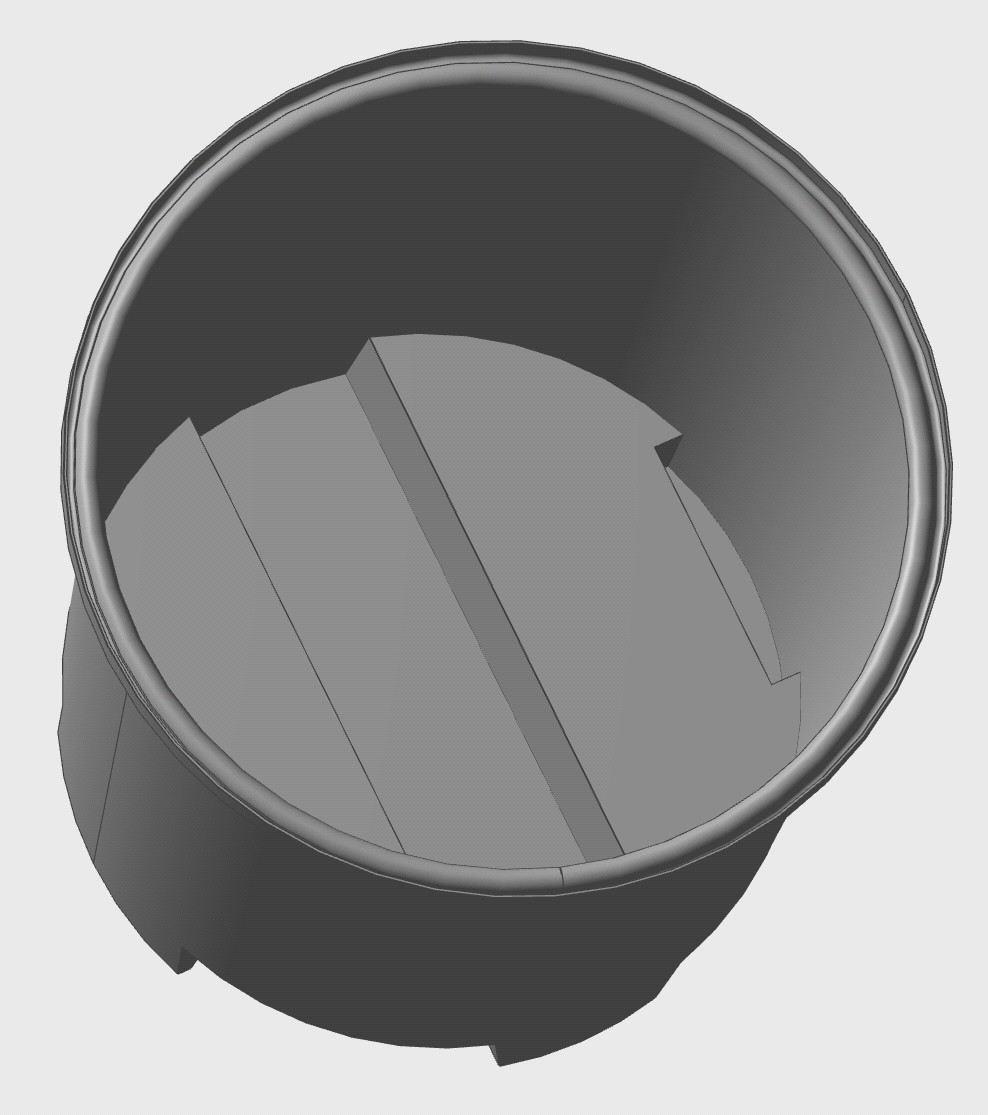

Three hundred liters of forklift bucket mold for making plastic products.

Another consideration is in the draft angles. These are required to remove the piece from the mold. On the outside walls, a draft angle of 1° may work (assuming no rough surface or holes). On inside walls, such as the inside of a boat hull, a draft angle of 5° may be required. This is due to shrinkage and possible part warping.

Another consideration is of structural support ribs. While solid ribs may be desirable and achievable in injection molding and other processes, a hollow rib is the best solution in rotational molding. A solid rib may be achieved byinserting a finished piece in the mold, but this adds cost.

Rotational molding excels at producing hollow parts. However, care must be taken when this is done. When the depth of the recess is greater than the width there may be problems with even heating and cooling. Additionally, enough room must be left between the parallel walls to allow for the melt-flow to move properly throughout the mold. Otherwise webbing may occur. A desirable parallel wall scenario would have a gap at least three times the nominal wall thickness, with five times the nominal wall thickness being optimal. Sharp corners for parallel walls must also be considered. With angles of less than 45° bridging, webbing, and voids may occur.

| Raw Material | Steel |

| Hardness | High |

| Thickness | 2.5 to 3mm |

| Product Specifications | CY-300L |

| Production Method | Forging |

| Use | Plastic forklift bucket production |

| Color | Customizable |

| Brand | Yutai |

The plastic forklift bucket is light in weight, convenient to handle, large in capacity, and convenient to clean.

The rotomolding mold has no hot runner, cooling groove, etc., and the structure is relatively simple; the product molding process is pressureless molding, so the mold wall thickness is relatively thin and the structure is simple.

Rotomolding products have good one-time molding integrity, relatively high material utilization rate, no welding, and no leakage.

Mold production time and manufacturing costs are relatively small, and maintenance and repair are relatively easy. Molds of different sizes and different tonnages can be customized according to requirements.

Plastic products have strong impact resistance, high tensile

strength, good oxidation resistance and aging resistance. Compared

with traditional anti-corrosion storage tanks, it is inexpensive

and cost-effective; plastic has the characteristics of internal and

external corrosion and can be placed in a strong corrosive

environment; and has excellent chemical resistance, can withstand

most substance solutions, except for a few that can make it

Swelling solution.

Company Introduction

Changzhou Yutai Mould Co., Ltd. is a set of design, manufacturing, sales as one of the mold machinery and equipment manufacturers, specializing in making all kinds of rolling and plastic machinery and equipment molds.With an experienced team of designers, providing one-stop services in mold design (SOLIDWORKS,UG,PRO/E,CAD), mold casting, model processing, surface treatment, mold specimens, etc.We produce rolling and plastic machinery and equipment molds include: barrels, square boxes, water tower, fishing boats, charge boats, tourist boats, transportation facilities and other specific rolling and plastic machinery and equipment, sales of all kinds of rolling and plastic plastic products, and exported to overseas around the world.

FAQ

Q1: Why choose us?

A:We are a professional manufacturer of mould.

Q2: Do you provide samples?

A:No, but we can provide drawings on request.

Q3: How long is your delivery time?

A:Generally 15 days to two months, slightly different according to the quantity and size.

Q4: What is your terms of payment?

A: Payment under USD1,000, 100% T/T in advance.

B: Payment more than USD1,000, 30% T/T in advance, balance before shipment.

Q5: What is your packing?

A: usually by wooden boxes, and can be packed as your require.