Shanghai Shenglin M&E Technology Co., Ltd. |

|

Crypto Cooling Mineral Oil immersion Cooling Hybrid Dry Air Cooler

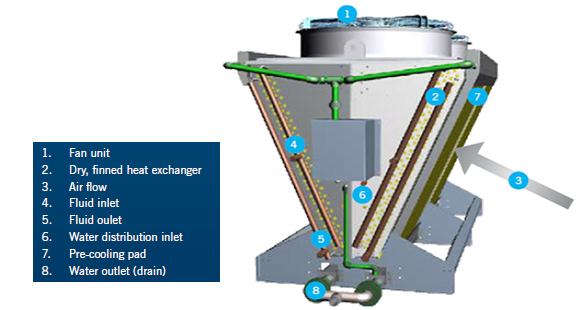

Adiabatic dry coolers combine the best of evaporative and dry cooling to optimize energy and water savings. Users can reduce peak energy use by 44% vs. traditional air-cooled products or reduce water use by 90% vs. traditional evaporative products.

For all of your commercial and industrial refrigeration application needs dry cooler, and fluid cooler models are available.

Principle:

Features of normal dry cooler

| High efficiency heat exchanger: capacity designs for maximizing the heat transfer relative to the energy consumption of the fan. Tube and tube coupling design for low pressure drop in the coil on the media sides(maximum 100KPa at water designing condition). Our thermodynamic and aerodynamic designing software is long year tested and proved in Germany |

| Fan: only choose low specific energy consumption fans. Fan nozzle designs for maximum air flow and air throw.Our fans from the world`s leading manufacturer are practically proved to be reliable in operation and long lasting. Motor: protection class IP 54 and insulation class F. Air separator for each fan. |

| We facilitate you to have a long lasting and low maintainance operation. Durable material and rigid enclosure with hard gloss powder coated finish. Protective enclosure for both manifolds and U-bends. Unit design for outdoor installation. 100% leakage tested at 31bar. |

Options

| Coil design refrigerant: water, oil, glycol. | Multiple circuits. |

| Sub-cooling circuits. | Stainless steel or aluminum casing. |

| Coated aluminum or copper fins. | Explosion proof motor. |

| Customized fin spacing. |

Technical parameter

Dry cooler FLAT SERIES SINGLE ROW FANS series parameter

| H*FS*91 H*FS*125 H*FS*180 | Van Dim mm | * | H*FS191 H*FS1125 H*FS1180 | H*FS291 H*FS2125 H*FS2180 | H*FS391 H*FS3125 H*FS3180 | H*FS491 H*FS4125 H*FS4180 | H*FS591 H*FS5125 H*FS5180 | H*FS691 H*FS6125 H*FS6180 | H*FS791 H*FS712 H*FS7180 | H*FS891 H*FS8125 H*FS8180 |

| Rated Capacities (kW) Heat Exchange Surface (㎡) | ||||||||||

| Fluid Coolers | 910 | D | 61kW-648kW 120㎡-2307㎡ (Water/Ta25℃/Tin40℃/Tout35℃) | |||||||

| 1250 | 138kW-1528kW 302㎡-4542㎡ (Water/Ta25℃/Tin40℃/Tout35℃) | |||||||||

| 1800 | 198kW-1920kW 363㎡-5084㎡ (Water/Ta25℃/Tin40℃/Tout35℃) | |||||||||

| Freon Condensers | 910 | F | 73kW-764kW 120㎡-2307㎡ (R404A/Ta35℃/Tk50℃) | |||||||

| 1250 | 166kW-1549kW 302㎡-4842㎡ (R404A/Ta35℃/Tk50℃) | |||||||||

| 1800 | 230kW-1920kW 330㎡-5103㎡ (R404A/Ta35℃/Tk50℃) | |||||||||

| Ammonia Condensers | 910 | A | 72kW-779kW 141㎡-2721㎡ (NH3/Ta35℃/Tk50℃ ) | |||||||

| 1250 | 181kW-1554kW 351㎡-5625㎡ (NH3/Ta35℃/Tk50℃ ) | |||||||||

| 1800 | 262kW-1986kW 421㎡-5907㎡ (NH3/Ta35℃/Tk50℃ ) | |||||||||

| Gas Coolers | 910 | G | 49kW-862kW 96㎡-1824㎡ ( CO2/Tair32℃/Tin113℃/P94Bar/Tout34℃) | |||||||

| Oil Coolers | 910 | O | 49kW-1041kW 120㎡-2307㎡ (OIL ISO VG 46/Ta35℃/Tin85℃/Tout60℃) | |||||||

| 1250 | 75kW-2021kW 302㎡-4842㎡ (OIL ISO VG 46/Ta35℃/Tin85℃/Tout60℃) | |||||||||

| 1800 | 92kW-2505kW 330㎡-5103㎡ (OIL ISO VG 46/Ta35℃/Tin85℃/Tout60℃) | |||||||||

| Fan Model | 910 | EC | W3G910KU2503 (2.55kW) or FN091-ZIQ.GL.V5P1 (3.2kW) | |||||||

| 910 | AC | W6D910GB0101 (2.02kW) or FN091-SDS.6N.V7P2 (1.85kW) | ||||||||

| 1250 | EC | 160M2-8P-5.5kW/720RPM/1250_5-5_LP_39°_PPG_9W2L | ||||||||

| 1250 | AC | 160M2-8P-5.5kW/720RPM/1250_5-5_LP_39°_PPG_9W2L | ||||||||

| No of Fans | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | ||

| Overall Dimensions | 910 | Lenth-1 | 1980 | 3480 | 4980 | 6480 | 7980 | 9480 | 10980 | 12480 |

| Lenth-2 | 2280 | 4080 | 5880 | 7680 | 9480 | 11280 | 13080 | 14880 | ||

| Width | 1230 | |||||||||

| Height | 1740 (Including 800Leg) | |||||||||

| 1250 | Lenth | 2600 | 4600 | 6600 | 8600 | 10600 | 12600 | 14600 | 16600 | |

| Width | 2280 | |||||||||

| Height | 1970 (Including 800Leg) | |||||||||

| 1800 | Lenth | 3000 | 5400 | 7800 | 10200 | 12600 | 15000 | 17400 | // | |

| Width | 2280 | |||||||||

| Height | 2170 (Including 1000Leg) | |||||||||

Application:

Industrial field: process engineering, heat / power plant, power generation, chemical industry, air conditioning chiller, heat transformer, smelting, etc.. It is suitable for all equipment which needs heat dissipation and is installed in the open air.

How to design a dry cooler?

Tell Shenglin the datas as following:

A. Required electrolyte inlet temperature?

B. Required electrolyte outlet temperature?

C. Electrolyte flow?

D. Ambient temperature?

E. Supply power(voltage-Hz-phase)

G. Any other requirements ?

Reference:

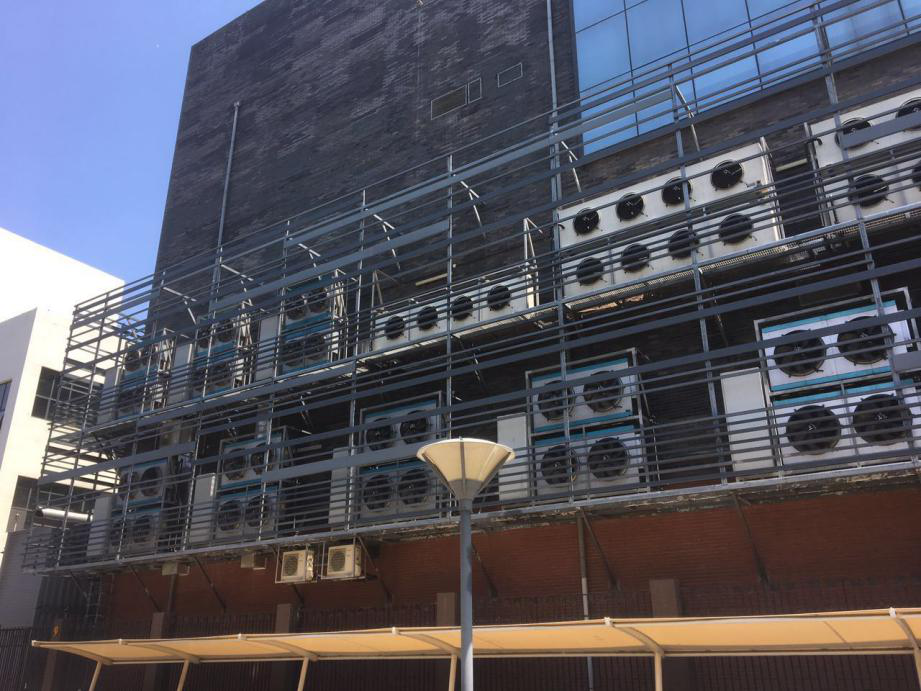

| Dry cooler case | |

| Case 1: used in chemical plant. | Case 2: used in chemical plant. Refrigerant: ethylic acid(flow: 372 ton/h) |

|   |

| Case 3: used in communication station as air conditioner outdoor unit in China. | Case 4: used in communication station as air conditioner outdoor unit |

|  |