Roofing Roll Forming Machine line

1). To design and make the best roll forming machine

2). Choose the best material and components, and adopting our 20+ years experience;

3). The machine working speed can be 20m/min;

4). Very easy to install and operate.

1. Specification of the material

| 1 | Suitable Material | PI/ PPGI |

| 2 | Width of the raw material | 914/1220mm |

| 3 | Thickness | 0.3-0.8mm |

2. Machine Detailed Parameters

| 1 | Roll Forming Machine | Roofing roll forming machine |

| 2 | Machine structure | Wall board structure |

| 3 | Total power | About 18.5kw |

| 4 | Roller stations | 22 stations |

| 5 | Productivity | 0-20m/min |

| 6 | Drive system | By chain |

| 7 | Diameter of shaft | ¢76mm solid shaft |

| 8 | Voltage | 480V 60Hz 3phases (Customized) |

| 9 | Color Of The Machine | Bule and yellow |

| 10 | Deliver time | 60 days |

| 11 | Terms Of Payment | 30%T/T 70% pay before shipment |

3. Profile drawing

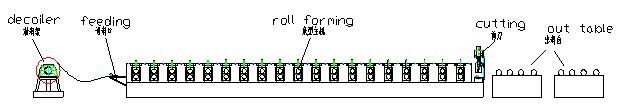

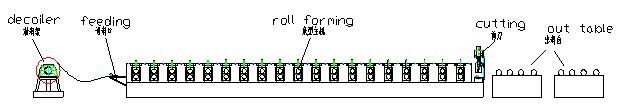

4. The Chart of Process Flow

Hydraulic Decoiler—Roll Forming—Cutting—Out table

5. Machine photos for reference

6. Specification of Components

(1) 5T Hydraulic Un-coiler

- Width of feeding: 1250mm

- Capability: 5 Ton

- Inter diameter: 460-560mm

- Maximal out diameter: 1600mm

- Working speed: 50m/min adjustable

- Main motor power: 7.5KW AC motor

- Hydraulic power: 4KW

- Speed controlled by frequency converter

- De-coiler should be with Loop control to prevent the material

falling to the ground.

- Color: blue

- Quantity: 1

(2) Main Roll Forming Machine

- Roller material:ASTM1045 chrome plated surface with chrome

- Shaft diameter: ¢76mm material: SAE1045 with quenching and

tempering

- Roll station: 22stations

- Main machine power: 11kw

(3) Machine Structure

- Main frame by 350H beam welding

- Machine structure: wall board

- Drive by chain

(4) Hydraulic cutting system

- Cutting after forming: Cut the sheet after roll forming to required

length

- Material of blade:Cr12, 58-62 HRC hardness

- Cutting power by hydraulic,7.5KW

- Working pressure: 12Mpa adjustable

- Length measuring: Automatic encoder length measuring

- Tolerance of length: +/- 1.5mm for each piece end product

(5) Computer Control Cabinet

- Programmable setting of profile length and quantity

- Operating system language: English and Chinese

- Computer used to control length & quantity. Machine will

automatically cut to length and stop when required quantity is

achieved

- PLC: Panasonic or customerization

- Touch screen: MCGS

- Inverter: YASKAWA

7. FQA

Q1. What are the main key points for selecting right machines?

A1: Whole structure,Roller Shaft,Roller Material,Motor&Pump,and

Control system. As the new buyer, please kindly know that price not

the final point. Good quality is for long-term business

cooperation.

Q2. Can you provide OEM service for roll forming machine?

A2: Yes, most of cold roll forming machine need to be customized as

detailed request, because raw material , size , production usage,

machine speed, then machine specification will be some different.

Q3. What’s your standard trade terms ?

A3: We can provide the technical offer with FOB,CFR,CIF,and so on.

Please kindly tell the detailed port name for competitive ocean

freight.

Q4. How about the after-sale service?

A5: We provide 18 months free warranty and free technical support

for the whole life of any machine. During warranty period, if parts

still broken, we can send the new ones freely.