Botou Golden Integrity Roll Forming Machine Co., Ltd |

|

Verified Suppliers

|

|

Galvanized Steel Metal Floor Decking B Roof Deck Sheets Cold Roll Forming Machine Price

1. Description of floor decking roll forming machine:

Floor decking Roll Forming Machine is a steel deck profile cold roll-machine. The floor decking Roll Forming Machine use PLC control,it’s very easy to operate. The machine realizes continuous production automatically. This cold roll forming machine is energy-saving and high-effective to producefloor deck .Floor decking Roll Forming Machine is used to manufacture deck floor for steel-structured buildings in constructional engineering.

Metal deck can be used for a variety of applications. Two of the most common types of metal deck are roof deck and floor deck. B Deck is the most common structural roof deck. It is also our top-selling metal deck. Typically B Decking is the ideal solution for short to medium span applications in roof, canopies, and awning construction.

2. Technical details of floor decking roll forming machinery:

| floor decking roll forming Machine Specifications | |

| Weight | About 12tons |

| Size | About 14mx1.4mx1.3m(length x width x height) |

| Color | Machine Main color: blue or can as your requirement |

| Warning color: yellow | |

| Suitable Raw Material | |

| Material | Galvanized Steel Coils,color steel |

| Thickness | 0.8-1.5mm |

| Yield Strength | 235Mpa |

| Main Technical Parameters | |

| Quantity of forming rollers stations | 26stations |

| Diameter of forming rollers shafts | 95mm |

| Roll Forming Speed | 15-20m/min |

| Forming rollers material | No.45 steel, coated with chromed treatment |

| Cutter material | CR12 mould steel, with quenched treatment |

| Controlling system | PLC and Converter |

| Electric Power requirement | Main motor power: 18.5kw+18.5kw |

| Hydraulic unit motor power: 5.5kw | |

| Electric voltage | According to customer’s requirement |

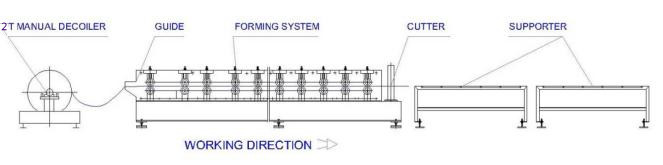

3. Main components of floor decking roll forming machine

| Decoiler | 1 Set |

| Guiding Equipment | 1 Set |

| Roll Forming Unit | 1 Set |

| Post Cutting Unit | 1 Set |

| Hydraulic Station | 1 Set |

| PLC Control System | 1 Set |

| Reveiving Table | 1 Set |

4. Production Flows

Uncoiling the sheet---Infeed guiding--Roll forming---Rectifying the straightness---Measure length---Cutting the panel--panels to the supporter (option: automatic stacker)

5. Advantages

We are very rigorous in every tiny detail,including raw material and making machines.

6. Application

This machine is widely used in the production of the roof and floor systems. Metal floor decking roll forming machine popular sell in many countries, such as United States, Mexico, Chile, Peru, Australia, Rwanda, Nigeria, Kenya, Dubai, Qatar, Thailand, India, Indonesia, Malaysia, Colombia Coil width before rolling is 1200mm /1220mm / 1250mm. Material common is PPGI material, material thickness common between 0.8-1.5 mm.

7. Product photo

FAQ

Q. Can you be responsible for transport?

A: Yes, please tell me the destination port or address. we have rich experience in transporting.

Q. How to visit your company?

A: 1) Fly to Beijing airport, By high speed train From Beijing Nan to Cangzhou Xi (1 hour).

2) Fly to Shanghai Airport: By high speed train From Shanghai Hongqiao to Cangzhou Xi(4.5 hours), then we can pick up you.

Welcome to inquiry.