FRIENDSHIP MACHINERY CO,LTD |

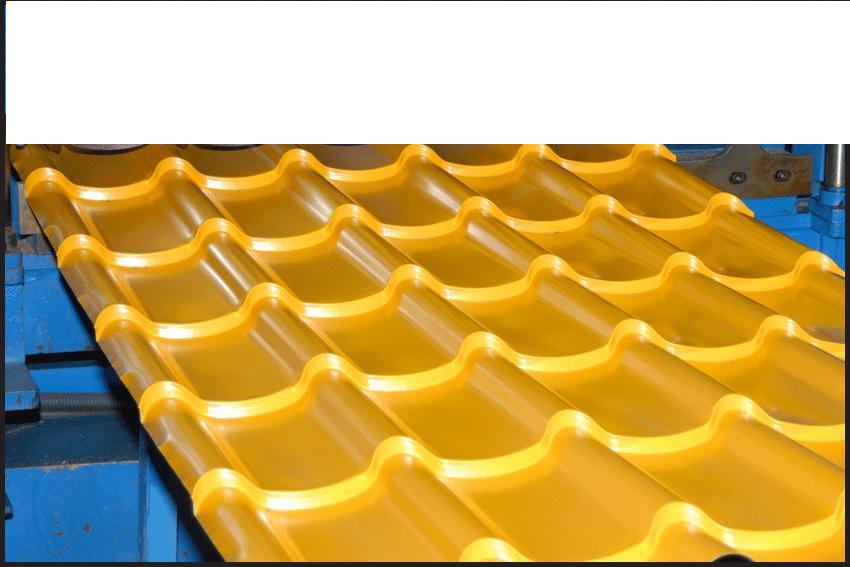

Hydraulic Cutting Glazed Tile Roof Roll Forming Machine High Efficient

General Description

This series high speed tile forming machine is a

new-generation type with high speed and high-efficient ,including

decoiler system,sheet guiding system,roll forming system,pressing

system,cut system,auto-stacker system,hydraulic system,controlling

system etc.

We can customize machine according to your

requirements.

Specifications of Tile Roll Forming Machine

Material thickness: 0.2-0.8mm,Color Steel, Galvanized coil

Material width: depend on customer’s requirement

Decoiler Type: manual or automatical type (depend on customer’s requirement )

Weight Capacity Of Decoiler: 5 Ton

Main Motor Power: 5.5 Kw

Hydraulic Motor Power: 11 Kw

Forming Station: 12-18 ( depend on profile drawing )

Material of Roller: High grade 45# forge steel, Polished and coated with 0.05mm Chrome Surface.

Main Axis Material: High grade 45#, quenched and heat treatment.

Axis Diameter: ¢ 75mm

Working Speed: 0-15 m/min

Transporting Type: Chain Transmission

Heat Treatment of Cutting Blade: HRC 50-60

Type of Cutting: Hydraulic cutting

Material Of Cutting Blade: C r 12

Heat Treatment of Cutting Blade: HRC 50-60

Machine Frame stand: Welded structural steel

Thickmess of Fame Steel: 18mm

Electrical Control: PLC Frequency Control System with touch screen

PLC: PANASONIC Brand

Encoder: OMRON Brand

Transducer: PANASONIC Brand

Machine Weight: about 8.5 Ton

Main Components

| Decoiler | 1 Unit |

| Film covering device | 1 Unit |

| Feeding guide | 1 Unit |

| Main roll forming machine | 1 Unit |

| Hydraulic pressing device | 1 Unit |

| Hydraulic cutting device | 1 Unit |

| Hydraulic Station | 1 Unit |

| PLC computer control | 1 Unit |

| Output table | 1 Unit |

Working Flow

Decoiler --- Fedding Guide --- Film Covering --- Roll Forming ---

Pressing --- Cut-to-length --- Run out table

Application

This roof panel used as the roofing of factory, warehouse. It is easy to realize the reliable and safety installation.

Good toughness: with super toughness, Tere is no necessary to do any treatment amontg the nail hole, it is sealing and can prevent leaking water.

Long life: life ≥ 25 years, is an alternative to steel sheet

Corrosion resistance: strong acid, alkali, salt, anti-static, anti-vapor corrosion, etc.

Noise performance: noise performance is good, away from the noise.

The appearance of the shape: color and length can be arbitrarily chosen.

Character of Main Structure

The structure is simple and the appearance of the machine is beautiful because we adopt the shape-steel structure and process as a whole after welding. It has the ability of strong loading and stable operation when running the machine.

All the components of machine are from brand-famous enterprise so that they ensure the machine normal function very effectively.

We adopt the automatic length-fixed forming and cutting to guarantee the length to be precise and the finished product clear without deforming .

It is very easy to install the equipment and suitable for producing in the factory.

The machine has features of low noise and high efficiency.

Introduction

We, Friendship Machinery Co.,Ltd, attaches great

importance on technology innovation,progress has been made on

scientific management as well as Co.,culture.China leading expert

in designing and manufacturing equipments for welding and cutting,

automation system and metal works. We use and produce

high-technology utilizing the most available robotic and automatic

techniques. Every work is uncompromisingly designed to improve our

clients' competitiveness and productivity.

We invest more on developing roll forming

machine such as Metal roof & wall panels machines,C&Z

purlin machines drywall Stud-track forming machines,Metal decks

machines,No-girder and Column curves forming machine,Guard rails

forming machines,Downspout pipes forming machines and so on.With

fast development ,very short period for construction and beautiful

external appearance,as well reasonable price was occupied in the

market of building industry.

EXCELLENT QUALITY AND COMPETITIVE PRICE !

CHOOSE US , CHOOSE THE BEST !

Thank you for your time !