Jiangyin Dingbo Technology Co., Ltd |

|

Verified Suppliers

|

|

A drywall stud and track roll forming machine is a specialized piece of equipment utilized in the construction industry to produce metal studs and tracks used in drywall framing systems. These components play a crucial role in the construction of interior walls and ceilings, providing the necessary structural support for gypsum board or other wall finishing materials.

The roll forming process is a cost-effective and efficient technique for manufacturing these components in large quantities. This method involves continuously feeding metal stock into a series of roll stations, where it is shaped and cut to the desired dimensions. This allows for precise and consistent production of drywall studs and tracks, meeting the high demand of the construction industry.

Investing in a drywall stud and track roll forming machine can greatly benefit construction companies, as it not only increases productivity and reduces labor costs, but also ensures the quality and reliability of the components. With this specialized equipment, construction projects can be completed efficiently and successfully, meeting the needs and standards of clients.

Features:

Features:

The production process of stud and track begins with a material feeding system, which is responsible for accepting coils of galvanized steel or other suitable metal. These coils, also known as raw material, are used to create the final product.

Upon loading the steel coils onto a decoiler, the metal strip is unraveled and fed into the roll forming machine.

The most essential part of the machine is the roll forming stations, consisting of a series of rollers and dies that progressively shape the metal strip into the desired profile of the stud or track. Each station plays a specific role in forming different parts of the profile.

After the metal strip is shaped, a cutting system is utilized to cut the continuous length of the material into individual studs or tracks of the required length. This can be achieved through the use of a flying cutoff or a stationary shear.

Additionally, some roll forming machines include punching and embossing stations. Punching creates holes or slots in the studs for wiring or plumbing purposes, while embossing adds strength to the material.

Once the studs and tracks are cut and formed, they are usually stacked or collected in an organized manner for easy handling and transportation.

Modern machines come equipped with a control system that allows operators to set parameters such as the desired length of studs or tracks, the number of punched holes, and other specifications. This ensures precision and consistency in the production process.

Many roll forming machines are designed to be adjustable, enabling quick changeovers between different stud and track profiles. This versatility is essential for meeting the various requirements of construction projects.

Technical Parameters:

| Items | Specifications | |

| Material of Coils | Material | Galvanized |

| Width of material | As per sketch | |

| Thickness | 0,4-0,6 mm | |

| Manual decoiler | 3 Tons | |

| Roll forming | Rolling Speed | 0-20m/min |

| Roller Stations | 13 stations | |

| Roller Material | 45#steel | |

| Shaft Material | 45#steel | |

| Shaft DIA | D56mm | |

| Main Motor Power | 2.2kw | |

| Side Plate | Wall plate | |

| Way of Drive | By chain | |

| Sizes adjust | Manually adjust by change spacers | |

| Servo cutting | Hydraulic Power | 3KW |

| Servo motor power | 1.1KW | |

| Mould and Blade Material | Cr12Mov | |

| Blades | 3 pieces | |

| Tolerance | +-1.5mm | |

Electrical control system

| Electric Source | 380V, 50HZ |

| PLC Control | Panasonic |

Main Items

Main Items| No. | Name | Qty |

| 1 | Manual uncoiler | 1 |

| 2 | Main roll forming machine | 1 |

| 3 | PLC control box | 1 |

| 5 | Hydraulic station | 1 |

| 6 | Output table | 2 |

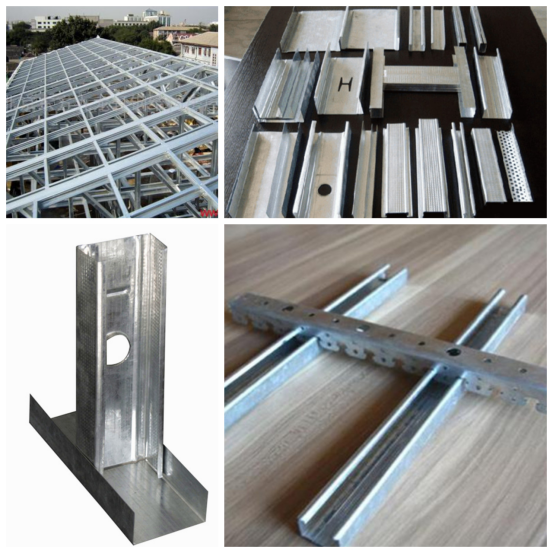

Drywall studs and tracks are essential components in the construction industry, especially for framing interior walls and ceilings. These versatile materials have found widespread applications in various construction projects, from residential buildings to commercial spaces and institutional structures.

Drywall studs and tracks play a crucial role in the construction of residential buildings, including single-family homes, apartments, and condominiums. They form the framework for interior walls and ceilings, providing a sturdy base for the installation of gypsum board and other wall finishing materials.

In commercial buildings, such as offices, retail spaces, and warehouses, drywall studs and tracks are extensively used for partition walls and other interior structures. These components not only contribute to the overall structural integrity of the building but also allow for the creation of functional spaces.

Drywall framing is also prevalent in institutional buildings, such as schools, hospitals, and government facilities. The versatility of studs and tracks enables the efficient construction of various room configurations and layouts within these structures. They also provide a sturdy base for soundproofing and fire-resistant materials, enhancing safety and functionality.

Packing and Shipping:

The Deck Floor Roll Forming Machine is carefully packaged and shipped to ensure safe delivery to our customers. Here are the details of our packaging and shipping process:

Once the package arrives at its destination, our customers can expect a smooth delivery process. Our team works closely with trusted shipping partners to ensure timely and safe delivery of the Deck Floor Roll Forming Machine.

FAQ

1. Q: What's the warranty period? (24hours online)

12 months warranty period, starting from the date of the successful installation and commissioning of the equipment at the Buyer’s Installation site. During which all parts damaged because of quality problem will be changed for free.

2. Q: Do you have installation and commissioning service?

A: If buyers come to our factory to inspect, the training to install and operate is provided face to face. If not, manual and video is provided to show how to install and operate.

B: If buyer need we will send technician to buyer site to do installation and commissioning and training.

C: installation and commissioning cost: One engineer will visit Buyer’s workshop for installing, commission and training. The buyer has to pay USD100 per day and visa fee, air tickets fee, accommodation and food, necessary communication, etc.

(Normally ,It takes about a week to install )

3. Q: What’s your after-sales service ?

We provide 24-hour online service for our customers.

And we are happy to give advice and also have skilled technicians available to maintain the machine overseas to customers’ workshop if needed.

4. Q: What's your delivery time ?

Normally we can finish production and testing within 45-70 days after receiving deposit. Some machines in stock, can be delivered at any time

5. Q: You are trading company or factory?

We are Manufacturer, and we export our machine by ourselves.

6. Q: Do you provide customized machine?

Sure, we can design the machine according to the requirement and profile drawing you provide. Our engineers can offer the best professional solution to our worldwide clients.

7. Q: How to visit your factory?

We are in jiangyin city,belongs to Jiangsu province, near Shanghai. If you

arrive at Shanghai Airport,we can pick you up(It is 160 kilometers from

Pudong Airport, about 3 hours.

It's 110 kilometers from Hongqiao airport, about 2 hours; It's 125 kilometers from downtown Shanghai about two and a half hours.

It is very convenient.Please let me know if you have booked the tickets

so that I can prepare and book a hotel for you,we will arrange for car to pick you up.

By high speed train from Shanghai to East Wuxi (Wuxi Dong station), half an hour.

8. Q: How to place order ?

Inquiry---confirm the profile drawings and technical specification and price--- confirm the PI--- arrange the deposit or L/ C--- start production-- do inspection--- Shipment

9. Q: What certificate do you have ?

We have CE and ISO certificate.

10. Q: What are your terms of payment ?

First payment: 40 % by T/ T, second payment: 60% by T/ T, after the successful inspection at seller’s workshop, and before delivery.

11. Q: What can you do if the machine breaks down?

We have 12 months warranty period, if the broken parts can not be repaired, we will send new parts to replace the broken for free.But if the warranty period is over,you need to pat the express fee.We can solve problems through negotiation and provide technical support for the whole life of equipment .