ZHENGZHOU SHINE ABRASIVES CO.,LTD |

|

Verified Suppliers

|

|

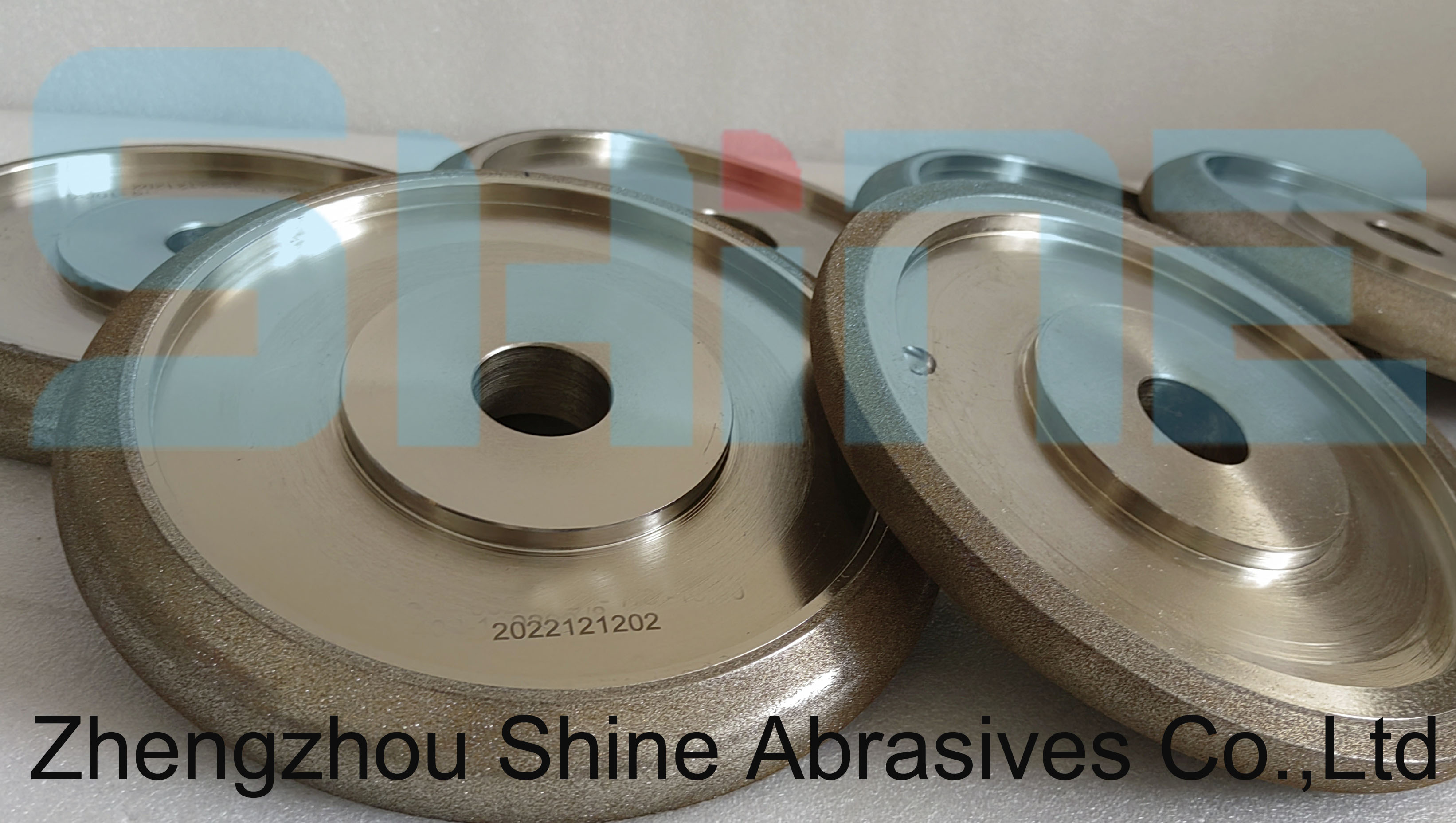

Electroplated diamond tools are widely available and offer a low environmental impact. They come in a variety of sizes, shapes and abrasion resistances, which can be customized to suit any application. Commonly used electroplated diamond tools include electroplated saw blades and diamond profile wheels, which are available in 40#~1000#, and can be customized to fit any specific needs. These tools are highly resistant to abrasion, thus ensuring a long lasting product that can be used in many applications.

| Parameters | Description |

|---|---|

| Process | Electroplating |

| Availability | Widely Available |

| Material | Diamond |

| Environmental Impact | Low |

| Cutting Speed | High |

| Abrasion Resistance | High |

| Shape | Customized |

| Cutting Efficiency | High |

| Corrosion Resistance | High |

| Application | Cutting, Grinding, Drilling, Polishing |

| Grain Size | 40#~1000# / Customized |

| Product | Electroplated saw blade, electroplated diamond tools |

Electroplated diamond tools are durable and designed for superior abrasion resistance. They are powerful tools used for cutting, grinding, drilling and polishing. With the brand name Electroplated Diamond&CBN grinding wheels and model numbers such as 1A1.6A2.9A3.11A2.4V2.6A9.3A1, they are manufactured in China and offer unparalleled cutting efficiency with a range of grit from 40#~1000# or more customized according to your needs. They are ideal for a wide range of applications, such as gemstone polishing, ceramic grinding, carbide grinding and more.

Our electroplated diamond tools are perfect for gemstone polishing and offer superior abrasion resistance and heat resistance. Our products are available in a range of grits from 40# to 1000# and can also be customized to fit your needs. Our tools come with a high cost but are worth it for the superior performance they offer.

At , we are committed to providing comprehensive technical support and service for our electroplated diamond tools. Our technical support team is available to answer any questions you may have and provide advice on product application, troubleshooting, and more.

We also offer a range of services to keep your electroplated diamond tools in top condition. These services include sharpening and sharpening verification, repair and reconditioning, and maintenance. Our trained technicians can also provide custom fabrication and modification services.

If you have any questions or would like to learn more about our technical support and service for electroplated diamond tools, please contact us. We are always happy to help.

Electroplated diamond tools are carefully packaged and shipped to ensure that they are not damaged during transit. The tools are placed in a foam-lined box or cushioned envelope. This helps prevent any damage to the tools during shipping. The box or envelope is then placed inside a sturdier box or container and sealed with tape. This provides extra protection against shocks and vibrations that can occur during transit.

All packages are shipped via a reliable carrier and tracked for delivery. The packages are insured to cover any potential damages that may occur during transit. Customers receive a tracking number for their order, so they can track the progress of their shipment.