Shanghai kangquan Valve Co. Ltd. |

|

Ductile Iron Silence Globe Needle Check Valve Flange End Epoxy

Coating

The Silent Check Valve is the preferred choice in applications

where silent operation and cost are major concern.

Its short linear stroke and spring return action combine to close

the valve prior to flow reversal which effectively eliminates the

shock and water hammer normally associated with the sudden stoppage

of a reverse flow.

Features:

⊙Professional design

The inner cavity of valve is designed as streamline shape, which can effectively stop the turbulence. The spherical surface is introduced to form the front of disc and cone contact for the seating couple; these structures will extremely the shock force of medium and decrease the resistance coefficient of flow. Thin shell structures is employed when design the diversion component to ensure the laminar flow and greatly drop the weight. The reasonable open height and cavity space enable the obtaining of maximum area of flow section. It can avoid occurring of the air chamber; the valve parameter Cv is improved.

⊙Excellent proof corrosion characteristics

Internal and external epoxy resin coating.

⊙Reliable hygiene principles

Epoxy resin and rubber comply with hygiene standard, the trim, such as disc, spring, etc., are made of stainless steel.

Mail part & material

Body, Line: GGG50 with internal and external epoxy resin coating

Disc: GGG50 or casting steel

Guiding stem, Spring: 1Cr17Ni12Mo2Ti, Stainless steel

Guiding bushing: Bronze CuAI10Fe3

Flange washer, O-ring: NBR, EPDM or FPM

Technical Specification

-Nominal diameter:50~350mm

-Nominal pressure:1.0/1.6Mpa

-Strength testing pressure:1.5/2.4Mpa

-Sealing testing pressure:1.1/1.76Mpa

Executive standard

Design standard | AWWA A508 |

Face to face | Enterprise standard |

Flange end | DIN 2501 |

Test & inspection | JG/T 9092-1999 |

Working temperature | NBR<80℃; EPDM<120℃; FPM<160℃ |

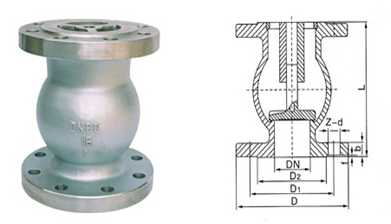

DN | L | Flange dimensions comply with GB/T17421.6-1998 | ||||||||||

O | C | g | f | b | n-d | |||||||

1.0MPa | 1.6MPa | 1.0MPa | 1.6MPa | 1.0MPa | 1.6MPa | 1.0MPa | 1.6MPa | 1.0MPa | 1.6MPa | |||

50 | 120 | 165 | 165 | 125 | 125 | 99 | 99 | 3 | 19 | 19 | 4-19 | 4-19 |

65 | 150 | 185 | 185 | 145 | 145 | 118 | 118 | 3 | 19 | 19 | 4-19 | 4-19 |

80 | 180 | 200 | 200 | 160 | 160 | 132 | 132 | 3 | 19 | 19 | 8-19 | 8-19 |

100 | 229 | 220 | 220 | 180 | 180 | 156 | 156 | 3 | 19 | 19 | 8-19 | 8-19 |

125 | 254 | 250 | 250 | 210 | 210 | 184 | 184 | 3 | 19 | 19 | 8-19 | 8-19 |

150 | 267 | 285 | 285 | 240 | 240 | 211 | 211 | 3 | 19 | 19 | 8-23 | 8-23 |

200 | 292 | 340 | 340 | 295 | 295 | 266 | 266 | 3 | 20 | 20 | 8-23 | 12-23 |

250 | 330 | 395 | 405 | 350 | 355 | 319 | 319 | 3 | 22 | 22 | 12-23 | 12-28 |

300 | 356 | 445 | 460 | 400 | 410 | 370 | 370 | 4 | 24.5 | 24.5 | 12-23 | 12-28 |

350 | 381 | 505 | 520 | 460 | 470 | 429 | 429 | 4 | 24.5 | 24.5 | 16-23 | 16-28 |