Shenzhen Honkia Prototype Co., Limited |

|

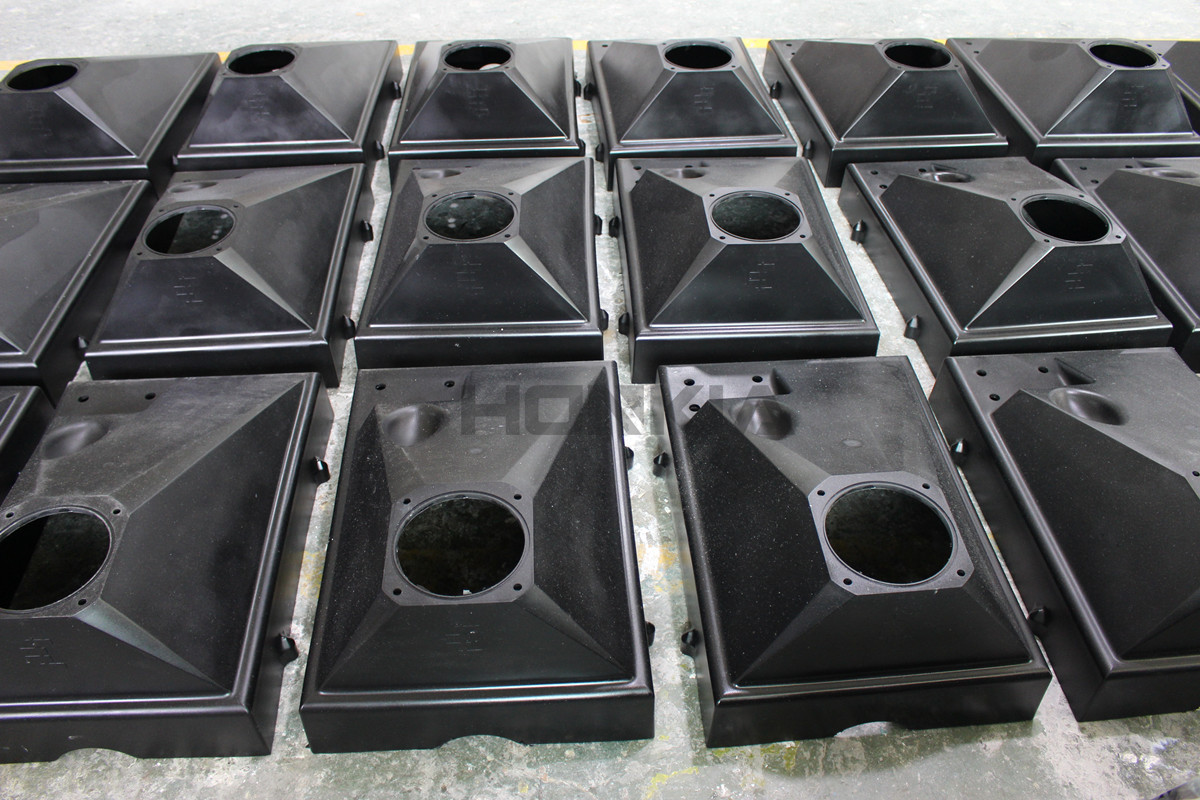

Reaction Injection Molding RIM Housing Parts Big Size Rapid Prototype To Production Cheap Price

Reaction Injection Molding (RIM) is an innovative manufacturing process used to produce the large and complex plastic parts with high flexibility, strength and durability. RIM involves the mixing of liquid bi-component polyurethanes in a mixer at certain amount ratio, then injecting the liquid mixture at room temperature and low pressure into mold cavity where the mixture reacts and cures into a solid part.

Advantages of RIM Parts:

Thick and Various wall thickness for one part

Excellent mechanical properties

High flexibility, strength and durability

Good chemical resistance

Great impact resistance

Excellent dimensional stability

This was an Engine Casing that was originally manufactured by the sheet metal fabrication with lots of welding. To save cost, customer modified the design of this casing to be Reaction Injection Molded. The different wall thicknesses of 5/7/10/20 mm brought challenge to shrinkage control.

The high pressures used cause the plastic to conform to the mold’s shape, thereby generating the part. Like metal die casting, custom plastic injection molding typically produces components that require little or no additional work. Reaction Injection Molding (RIM) is a specialized subset of the injection molding technique that chemically bonds two or more plastics into a polymer before they are introduced into the mold.

Our RIM tooling was usually made of Epoxy Resin & Silicone Rubber, the silicone rubber pieces were usually replaced after 100 shots. Low-Pressure & Room-Temperature Injection Molding required fairly low mold locking force, thus the simple clamps were fine for our RIM process.

RIM Parts Design Considerations:

When designing parts for RIM production, it's important to consider

factors such as size, structure, wall thickness, draft angles, and

gating. RIM parts can be designed with complex geometries and

intricate details, but it's important to ensure that the part

design is manufacturable and the tooling favors the design.

One shot of injection molding time was around 40 seconds. More big size and volume of the part, More time of the reaction injection molding. Insert Molding and Overmolding were also feasible for our RIM process. 4 stainless steel M6 nuts were inserted for injection molding.

We are respected in RIM industry in China, the RIM service we send out to global market are quick, economical and quality that are proven by the customers used our service, especially from automobile field. We look forward to doing more and better by our continuously improving RIM expertise and experience.

Industry Applications:

RIM is commonly used in the low volume manufacturing or prototyping

of automotive, aerospace, medical devices, and consumer goods

parts. Such as automotive bumpers & grills, body panels,

interior components, aerospace ducting, large enclosures, big

housings and medical covering shells.

We are a professional supplier. We know what we are doing. We keep a very stable quality level for years. Thanks to our professional production and technical team, our qualified products rate is 99.75% and we are constantly improving it, we hope our clients can get what they paid for.

Due to the low injection molding temperatures and pressures, RIM is well-suited for molding large parts with variable wall thickness and smooth surface finishes. We can also benefit from its relatively high turnover rate, which makes it proficient in handling low to middle volume production projects. In addition, RIM parts have high tensile strength, heat resistance, and good resistance to corrosive acids or solvents. However, prolonged exposure to sunlight can degrade polymer-based parts.

How does HONKIA compare to other suppliers on price?

Compared to other Chinese suppliers, we choose not to compete on price but to offer the high level of quality, rapid response, and professional results. That’s why some customers cooperate with us for many years, compared with the price, they need a reliable partner to avoid serious losses caused by annoying after-sales service or even the trouble of finding no one.

What if I am not completely satisfied with the parts I receive?

HONKIA will free remake or amend the returned parts that you are not completely satisfied, or refund the full arrived payment, though this is rarely happened in the past. Any disputes based on a subjective or unilateral determination shall be discussed and negotiated to reach a reasonable result. Our continuing business relies on earning your confidence in our ability to meet and exceed the reasonable expectations.